Overmolding is a cool way to make things better, like making a smartphone case more comfortable to hold or adding a logo to a tool handle. It’s done by putting a special rubber called Liquid Silicone Rubber (LSR) on top of something else.

What is Liquid Silicone Rubber (LSR)?

LSR is like super rubber. It’s flexible, can handle heat, doesn’t get hurt by chemicals, and is safe for medical stuff. It’s also really precise, which means it can make things that fit perfectly together. Plus, it doesn’t waste much material, which is good for the planet.

To learn more about Liquid Silicone Rubber

What is Overmolding?

Overmolding is a dynamic manufacturing process that involves the application of a second material, often a thermoplastic or elastomer like Liquid Silicone Rubber (LSR), over an existing substrate or component. This technique is used to create a seamless bond between the two materials, resulting in a single, integrated product. Overmolding serves a dual purpose:

- Enhanced Functionality: Overmolding can add new features, such as ergonomic grips, sealing, or cushioning, to a product that improves its functionality and user experience.

- Improved Aesthetics: It offers the opportunity to enhance the visual appeal of a product by adding colors, textures, or branding elements.

Key Characteristics of Overmolding:

- Material Compatibility: Overmolding requires careful consideration of the compatibility between the substrate and the overmold material. In the case of LSR overmolding, the material’s unique properties make it suitable for bonding with various substrates, including metals, plastics, and other elastomers.

- Precision: Overmolding demands precision in the molding process to ensure a seamless, reliable bond between the materials. Tight tolerances are crucial to achieving a high-quality end product.

- Versatility: Overmolding is versatile and adaptable to a wide range of industries and applications, from healthcare and automotive to consumer electronics and industrial equipment.

- Cost-Effective: While it may add an extra step to the manufacturing process, overmolding often leads to cost savings in the long run by reducing the need for additional assembly and improving product durability.

- Design Freedom: Designers have greater freedom to create products with complex shapes and ergonomic features, as overmolding can cover intricate details of the substrate.

In the context of LSR overmolding, this process harnesses the exceptional properties of Liquid Silicone Rubber to enhance products across various sectors. The versatility and compatibility of LSR make it an ideal choice for overmolding, offering manufacturers innovative solutions to meet specific design and performance requirements.

Benefits of Liquid Silicone Rubber (LSR) vs. Solid Silicone

Liquid Silicone Rubber (LSR) overmolding offers a plethora of benefits that have made it a preferred choice in various industries.

1. Enhanced Product Performance

LSR overmolding enables the creation of products with superior performance characteristics. The flexible and durable nature of LSR enhances the overall functionality and longevity of the final product. Whether it’s providing cushioning for electronic devices, sealing automotive components, or improving grip on tools and handles, LSR overmolding enhances product performance across a wide spectrum of applications.

2. Cost-Efficient Production

While LSR overmolding may involve an additional manufacturing step, it often leads to cost savings in the long run. The process reduces the need for post-molding assembly, which can be both time-consuming and costly. Moreover, LSR’s low material waste and efficient molding processes contribute to overall cost efficiency.

3. Seamless Bonding

One of the standout features of LSR is its excellent bonding capabilities. When used in overmolding, LSR creates a seamless and robust bond with a variety of substrates, ensuring that the overmolded material stays securely in place even under stress. This results in products that are highly resistant to delamination or separation.

4. Improved Aesthetics

LSR overmolding allows for the integration of colors, textures, and branding elements into the final product, enhancing its visual appeal. Manufacturers can create products that are not only functional but also aesthetically pleasing, making them more attractive to consumers.

5. Reduced Material Waste

The precise nature of LSR molding minimizes material waste during the manufacturing process. This aligns with sustainability efforts, as it reduces the environmental impact associated with excess material disposal.

6. Complex Geometries

LSR’s liquid form enables it to conform to intricate shapes and details, which is particularly advantageous when overmolding complex substrates. Manufacturers can achieve designs that might be challenging or impossible with other materials.

7. Regulatory Compliance

In industries like medical and healthcare, compliance with stringent regulatory requirements is paramount. LSR overmolding is favored for its biocompatibility and ability to meet medical-grade standards, ensuring the safety and reliability of products in sensitive applications.

8. Versatility

LSR overmolding is versatile and adaptable to diverse applications, from medical devices to automotive components and beyond. Its compatibility with various substrates allows manufacturers to explore a wide range of product possibilities.

The numerous advantages of LSR overmolding make it a go-to choice for manufacturers seeking to improve product quality, reduce costs, and enhance the overall user experience.

Challenges in LSR Overmolding

While Liquid Silicone Rubber (LSR) overmolding offers a host of benefits, it is not without its challenges.

1. Material Selection

Selecting the right LSR material is critical to the success of an overmolding project. Factors such as the substrate material, intended application, and regulatory requirements all play a role in determining the most suitable LSR material. Choosing an inappropriate material can lead to adhesion issues, poor bonding, or performance failures.

2. Tooling and Equipment

Achieving precise and consistent overmolding requires well-designed molds and specialized equipment. Tooling and equipment must be capable of maintaining tight tolerances and ensuring the proper flow of LSR. Improper tooling can result in defects, such as flashing or voids.

3. Quality Control

Maintaining high-quality standards throughout the overmolding process is crucial. Variations in LSR consistency, curing times, or environmental factors can impact the final product’s quality. Comprehensive quality control measures, including regular inspections and testing, are necessary to identify and rectify issues promptly.

4. Regulatory Compliance

Certain industries, such as medical and automotive, have stringent regulatory requirements for product safety and performance. Ensuring compliance with these regulations can be challenging and requires thorough documentation and testing procedures. Non-compliance can lead to costly delays or even product recalls.

5. Material Waste

While LSR overmolding is efficient in minimizing material waste compared to traditional manufacturing methods, there may still be instances where excess material is generated. Managing material waste responsibly is essential for sustainability and cost-effectiveness.

6. Design Complexity

Overmolding complex substrates or achieving intricate designs can be technically challenging. Designers and engineers must work closely to ensure that the overmolding process can accommodate the desired product features without compromising quality or manufacturability.

7. Process Control

Maintaining consistent process parameters, such as temperature and pressure, is essential for reliable overmolding results. Process control systems and operator training are necessary to achieve these tight controls.

8. Adhesion Issues

Ensuring proper adhesion between the LSR and the substrate is critical for the durability of the overmolded product. Surface preparation and bonding agents may be required to address adhesion challenges.

9. Cost Considerations

While LSR overmolding can lead to cost savings in the long run, the initial setup costs, including tooling and equipment, may be significant. Manufacturers need to assess the cost-effectiveness of LSR overmolding for their specific applications.

Liquid Silicone Rubber Overmolding Process

The Liquid Silicone Rubber (LSR) overmolding process is a carefully orchestrated sequence of steps that require precision and expertise. It combines the unique properties of LSR with overmolding techniques to create high-quality, integrated products. Here’s a step-by-step overview of the LSR overmolding process:

1. Material Preparation

The process begins with the preparation of the LSR material. LSR is a two-component material that consists of a base and a curing agent. These components are carefully measured and mixed to achieve the desired consistency and properties. The mixture is degassed to remove any air bubbles, ensuring a uniform material.

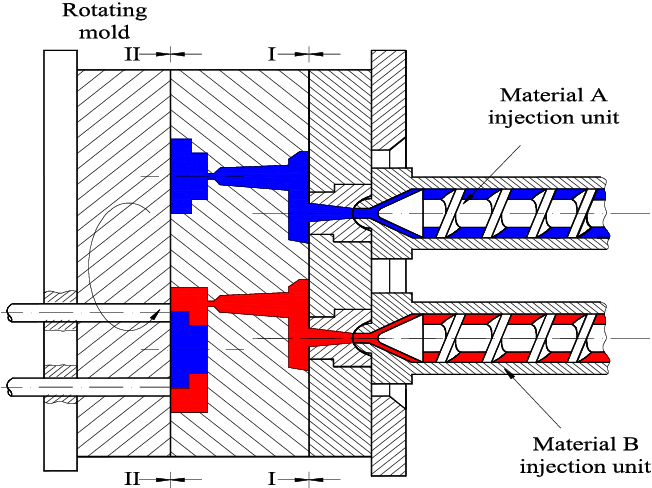

2. Injection Molding

In this phase, the LSR material is injected into a specially designed mold cavity. The mold is typically made of steel or other durable materials and is designed to match the desired shape of the overmolded part. Precision is key during injection to control factors such as temperature, pressure, and flow rate.

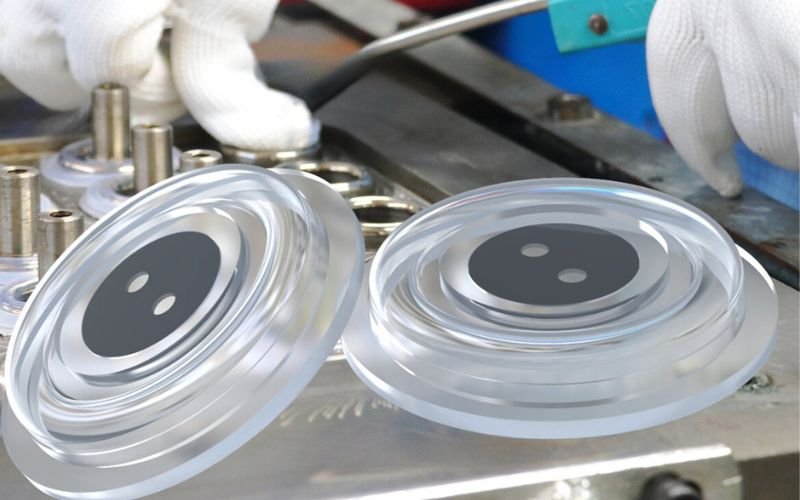

3. Overmolding

Once the initial LSR part is molded, it’s time for overmolding. The previously molded LSR component (the substrate) is securely positioned in a second mold. This mold is designed to accommodate both the substrate and the additional LSR material that will be added.

4. Curing

The mold with the substrate and LSR material is then placed in a curing oven or chamber. Curing is a critical phase where the LSR undergoes vulcanization, a chemical process that transforms it from a liquid to a solid elastomer. The curing time and temperature are carefully controlled to ensure optimal material properties.

5. Inspection and Quality Assurance

After curing, the overmolded product is carefully inspected for quality and adherence to specifications. This includes checking for defects, such as flashing or voids, and verifying that the overmolded material has securely bonded with the substrate. Quality assurance measures are taken to ensure the product meets the desired standards.

LSR Overmolding Applications

Liquid Silicone Rubber (LSR) overmolding has found wide-ranging applications across numerous industries due to its unique combination of flexibility, durability, and versatility.

1. Medical Devices

LSR overmolding is extensively used in the medical and healthcare industry for creating components such as:

- Medical Gaskets and Seals: LSR’s biocompatibility and resistance to body fluids make it ideal for producing seals and gaskets for medical devices.

- Drug Delivery Systems: LSR is used to create specialized components for drug delivery devices, ensuring precision and reliability.

- Surgical Instruments: Overmolding enhances the grip and comfort of surgical instruments, improving the surgeon’s precision and reducing fatigue.

2. Automotive Components

In the automotive sector, LSR overmolding plays a crucial role in:

- Automotive Seals: LSR provides excellent sealing properties, making it suitable for gaskets, O-rings, and weather seals.

- Interior Components: Overmolded buttons, knobs, and grips enhance the functionality and user experience of automotive interiors.

- Wire Harnesses: LSR overmolding offers reliable insulation and protection for wire harnesses and connectors.

3. Consumer Electronics

LSR overmolding is used in various consumer electronics products to:

- Enhance Durability: Overmolding reinforces fragile electronic components, protecting them from impact and wear.

- Improve Aesthetics: LSR overmolding allows for the integration of vibrant colors and textures, enhancing the visual appeal of devices.

- Ensure Ergonomics: Overmolded grips and handles provide ergonomic benefits for handheld devices.

4. Infant and Childcare Products

LSR overmolding is a popular choice for infant and childcare products, including:

- Baby Bottle Nipples: LSR offers a safe and soft material for baby bottle nipples, mimicking the natural feel of breastfeeding.

- Teething Toys: Overmolding provides a comfortable and durable surface for teething toys, ensuring baby safety and satisfaction.

5. Industrial Equipment

In industrial applications, LSR overmolding contributes to:

- Tools and Machinery Components: Overmolding improves the grip and durability of tools and equipment used in various industries.

- Sealing Solutions: LSR is utilized for creating effective seals in industrial machinery, ensuring reliable performance.

6. Agriculture

In the agricultural sector, LSR overmolding is used in:

- Agricultural Equipment Components: LSR enhances the longevity and functionality of parts used in agricultural machinery.

7. More

Beyond these industries, the adaptability of LSR overmolding allows for a wide array of applications, including in the aerospace, telecommunications, and sporting goods sectors.

Future and Potential of LSR Overmolding

The future of Liquid Silicone Rubber (LSR) overmolding is marked by exciting possibilities and innovations that have the potential to reshape manufacturing processes and product design across industries.

Advancements in Material Science

Ongoing developments in material science are leading to the creation of even more advanced LSR formulations. These materials may offer enhanced properties, such as increased strength, improved heat resistance, or new levels of flexibility, opening up new application possibilities.

Sustainable Manufacturing

The growing emphasis on sustainability in manufacturing is driving innovations in LSR overmolding. Efforts to reduce material waste and energy consumption are expected to result in more environmentally friendly LSR overmolding processes.

Miniaturization and Micro-Molding

As electronic devices and components continue to shrink in size, LSR overmolding is poised to play a crucial role in micro-molding applications. The

precision and versatility of LSR make it an ideal choice for molding small and intricate parts.

Integration with Industry 4.0

The integration of LSR overmolding processes with Industry 4.0 technologies, such as automation, robotics, and data analytics, is expected to enhance efficiency, quality control, and traceability in manufacturing.

Customization and Personalization

Consumers’ increasing demand for customized products presents an opportunity for LSR overmolding to shine. Manufacturers can use this process to create bespoke products tailored to individual preferences and needs.

Expansion into Emerging Markets

LSR overmolding is gaining traction in emerging markets, particularly in regions with growing healthcare and automotive sectors. As these markets continue to evolve, LSR overmolding is likely to play a significant role in their manufacturing landscape.

Cross-Industry Collaboration

Collaborations between LSR manufacturers, material suppliers, and end-users are fostering innovation. The exchange of knowledge and expertise is leading to the development of new LSR applications and solutions.

Regulatory Evolution

In highly regulated industries like healthcare and automotive, the regulatory landscape is continuously evolving. LSR manufacturers are expected to adapt to these changes, ensuring their products meet the latest compliance standards.

Enhanced Design Tools

The availability of advanced design and simulation tools allows engineers and designers to explore complex LSR overmolding designs more easily. This facilitates the creation of innovative products.

The future of LSR overmolding is a dynamic landscape where technology, sustainability, customization, and collaboration converge to create exciting opportunities for manufacturers and end-users alike. As this innovative manufacturing technique continues to evolve, its role in product design and development is set to expand, driving advancements in a wide range of industries.

Custom LSR Overmolding Solutions from Ruiyang Silicone

In the world of Liquid Silicone Rubber (LSR) overmolding, selecting the right manufacturing partner is paramount to the success of your project. Ruiyang Silicone, with its decade-long experience and commitment to excellence, stands as a trusted partner in providing custom LSR overmolding solutions to meet the unique needs of various industries.

Contact Ruiyang Silicone today to explore how our custom LSR overmolding solutions can benefit your industry and take your products to new heights of functionality and aesthetics.