Silicone rubber strips are versatile components used in various industries due to their durability and flexibility. Have you ever wondered how these essential products are manufactured? Let’s dive into the intricacies of the silicone rubber strip manufacturing process.

What is Silicone Rubber?

Silicone rubber is a synthetic elastomer prized for its heat resistance, low chemical reactivity, and biocompatibility. It’s widely used in industries ranging from automotive to healthcare.

Silicone Rubber Strip Manufacturing Process

1. Raw Materials and Preparation

The manufacturing process begins with selecting high-quality raw materials. Silicone polymers, fillers, cross-linkers, and additives are carefully chosen to achieve desired properties such as hardness and resilience.

2. Mixing and Compounding

These ingredients are precisely mixed in batch or continuous mixing equipment to ensure uniform distribution. Proper mixing is crucial to avoid defects and ensure consistent product quality.

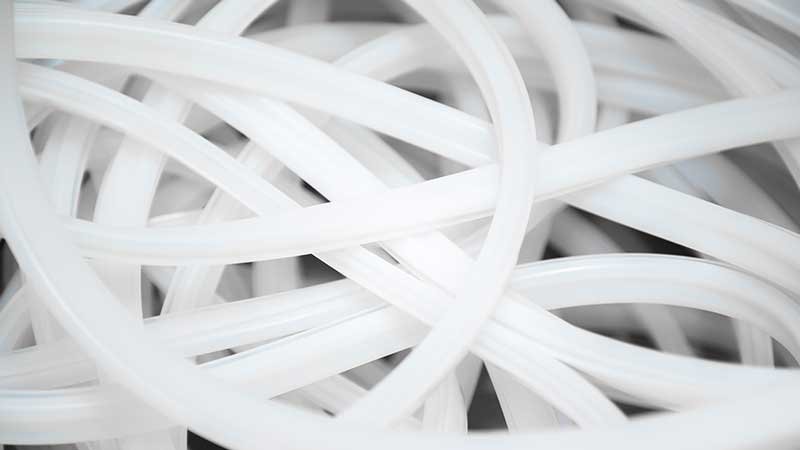

3. Extrusion Process

Once the compound is ready, it undergoes an extrusion process. In this step, the silicone material is forced through a die to create a continuous profile in the form of a strip. Extrusion machines play a pivotal role in shaping the silicone into the desired dimensions and profiles.

4. Curing and Vulcanization

The extruded silicone strip is then cured or vulcanized to enhance its mechanical properties. Curing typically involves subjecting the strip to heat for a specific period, allowing cross-linking of polymer chains. This step determines the final hardness and elasticity of the silicone rubber.

5. Cutting and Finishing

After curing, the silicone strip is cut to the required length and undergoes finishing processes such as surface treatment or printing. These steps add functionalities or aesthetic appeal to the final product.

6. Quality Control

Throughout the manufacturing process, stringent quality control measures ensure that the silicone strips meet industry standards and customer specifications. Testing for physical properties such as tensile strength, elongation, and hardness is conducted to validate product integrity.

7. Applications and Industries

Silicone rubber strips find applications in various industries, including automotive seals, electronic gaskets, medical devices, and aerospace components. Their versatility and reliability make them indispensable in modern manufacturing.

Why Choose Silicone Rubber Strips?

Silicone rubber strips offer superior performance in challenging environments due to their thermal stability and resistance to UV exposure and chemicals. Their ability to maintain elasticity over a wide temperature range makes them ideal for diverse applications.

Conclusion

Understanding the silicone rubber strip manufacturing process highlights the precision and innovation involved in producing these essential components. Whether for sealing, insulating, or protecting, silicone rubber strips play a crucial role in modern industry.

Related:

Silicone Products Manufacturing Process