Silicone products are widely used in many fields because of the features of non-toxic, tasteless, high-temperature resistance, stable performance, etc. In our daily life, silicone products can be found everywhere from silicone baby feeding to silicone kitchen utensils, from auto parts to medical equipment, and from beauty products to consumer goods, like silicone toys and gifts.

Silicone rubber products are welcome not only because of their high-quality physical properties but also because their chemical structure is based on alternating units of silicon and oxygen. They can be made with different organic and carbon bases, as well as additives and fillers integrated into their molecular framework to create products with different shapes, hardness or elasticity, color, transparency, tear strength, resistance to environmental or mechanical stress, and more.

How to Manufacture Silicone Products?

As a professional manufacturer of silicone products with many years of experience in the industry, Ruiyang silicone manufacturing processes include:

- Compression molding

- Liquid silicone rubber injection molding

- High-consistency rubber injection molding

- Extrusion molding

- Calendering molding

- Transfer molding

The choice of which process to use varies from product to product depending on the complexity of the silicone product structure, size, quantity, cost, special performance needs, etc. Therefore, it is critical to understand the materials and manufacturing processes to optimize silicone product quality, productivity, and consistency. Let’s take a closer look at these methods.

Compression Molding

Compression molding is a very common method for processing silicone. It is mainly done by the fit of the mold, and the shape of the mold determines the shape of the silicone product. The silicone is usually molded by high-temperature molds. First, the solid silicone raw materials are mixed with a vulcanizing agent. Then the material is pressurized through the vulcanizer to fill the whole cavity and vulcanized under high temperature, and the heating and pressure are maintained until the silicone is cured. During this process, the silicone rubber remains somewhat flexible, and the hardness of molded silicone is usually between 30°C and 70°C. This manufacturing process is relatively simple and applicable to the majority of silicone products.

Advantages of compression molding include

- Lower tooling cost

- Less waste of raw materials

- Cost-effective, especially for large parts and high-volume orders

- Suitable for small parts and more complex shapes

- Wide range of applications including computer keyboards, kitchen supplies, electrical parts, and some medical and dental equipment

Types of Compression molded Silicone Products

Baby silicone products, kitchen silicone products, household items, gaskets, sealing gaskets, O-rings, silicone duckbill valves, silicone custom auto parts, etc.

Injection Molding

Injection molding is more complex than compression molding, transfer molding, or extrusion molding. Short cure times and low viscosity make injection molding an excellent choice for a wide variety of silicone products. Mold design, gate size, and location are key factors in optimizing the injection molding process.

Using the injection molding process has the following benefits:

- Adapt to high-volume production

- Multiple materials can be used at the same time

- Can be automated

- Low production price per component

- Short molding cycle

- No prefab preparation required

- Under the correct mold design, no trimming is required

- Very suitable for products requiring dimensional tolerance or uniformity

Of course, in addition to the advantages, there are also some points that need to pay attention to in the process of using injection molding to produce silicone products.

- Flashing, warping, bubbles, dents

- Insufficient injection volume will cause the mold part to fail to fill

- In multi-cavity molds, balance gates to optimize material flow

- Venting with fast fill and short focus times may be necessary to eliminate trapped air

- Refreshing material mixtures prior to molding improves part yield

- Keep the cavity clean and identify

- Curing of the product

- Best for thin-walled products

Types of Injection Silicone Molded Products

Small precision parts, auto parts, swimming supplies, kitchen appliances

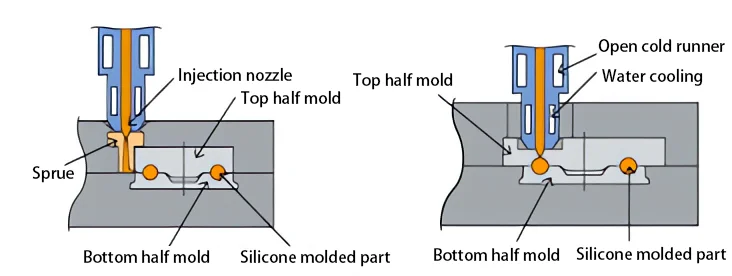

Liquid Silicone Rubber (LSR) Injection Molding

Liquid silicone rubber is a high-purity, two-component, cured silicone reinforced with specially treated silica. It has relatively high requirements for strength, resistance, and high quality. LSR is less viscous than HCR, making it a pumpable material ideal for liquid injection molding.

The main difference between LSR and HCR is the “flowable” or “liquid” nature of the LSR material. Also, while HCR can use peroxide or platinum curing processes, LSR only uses platinum additives. Due to the thermoset nature of the material, LSR injection molding requires special handling such as intensive distributive mixing while keeping the material at a low temperature before it is pushed into a heated cavity and vulcanized.

How does the LSR injection molding process work and what are its advantages?

LSR injection, like its HCR counterpart, is used to create a molded end product in a cavity. The LSR process uses an unheated liquid or viscous material that is pumped through an injection nozzle into the mold cavity. The raw material is simply conveyed under pressure into the closed heated cavity, filling the cavity in an instant. Due to its simplicity, LSR injection molding is a very fast manufacturing method, using a metering device to draw directly from the barrel, with fast turnaround times, ideal for producing very high volume parts.

Key advantages of LSR injection

- Short and precise molding cycles

- Mass production

- Efficient and economical processing

- Wide range of uses, can make a variety of general products

- Fast cure and excellent mold release

High Consistency Rubber (HCR) Injection Molding

High Consistency Rubber (HCR) is also known as Heat Cured Rubber or HTV (High-Temperature Vulcanized) Silicone Rubber. This material is made of reactive silicone with very high-weight macromolecules.

Various raw materials can provide specific functions for HCR, such as fumed silica or precipitated silica with a high specific surface area to improve mechanical properties, heat stabilizer, plasticizer, or anti-recombination agent.

HCR elastomers outperform traditional organic elastomers, providing superior mechanical strength in the temperature range of -50°C to +300°C. They also have good aging properties, are chemically inert, are stable when exposed to light or oxygen, and are easily colored and even transparent, making them ideal for food packaging and medical aid applications.

Incorporating various additives into HCR opens up limitless custom solutions for existing and new applications in various industries. Aerospace, Automotive, Healthcare, Oil & Gas, Construction, Electronics, Electric Vehicles, and more.

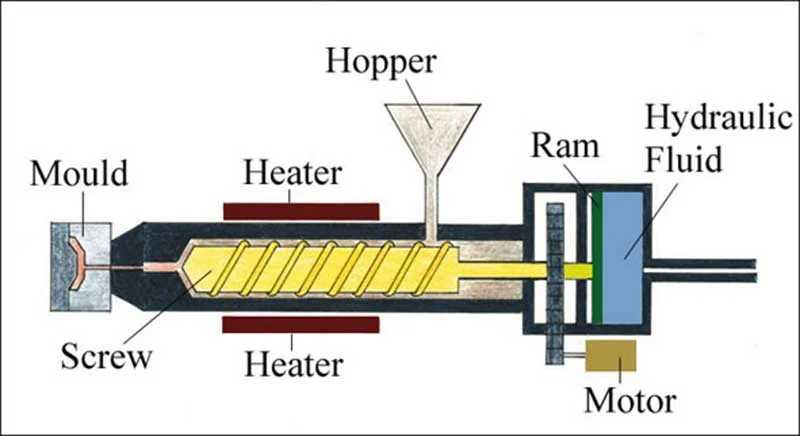

How does the HCR injection molding process work and what advantages does it yield?

Metered HCR is injected directly from the cylinder into the closed heated mold through the screw mechanism and nozzle, through the gate. The material fills and fills the cavity of the mold, forming the part.

The main advantages of HCR injection molding

- Short and precise molding cycles

- lower unit cost

- Less material waste

- Possibility of molding with other materials such as plastic or metal

- In terms of finished products, production is stable

- Superior accuracy and filling of complex parts compared to compression or transfer molding.

- It is arguably the most common and powerful method of forming, where products can vary widely in size, complexity, and application.

The difference between Compression molding and injection molding

Compression molding and injection molding are similar in that they both fill pre-formed cavities, but they differ in that compression molds are directly pre-filled with filler, whereas in injection molding, the filler is injected previously fully in a closed cavity.

Manufacturers of different types of parts often use both compression and injection molding, but for different types of parts. In general, injection molding is preferred when making more complex (and often smaller) parts, while compression works very well for simple or basic designs and large parts that cannot be produced using extrusion.

Other points of comparison include: injection molding has shorter cycle times and is therefore generally faster and more cost-effective for high-volume products, while compression molding is mostly used for low- to medium-production series parts.

Extrusion Molding

Extruded silicone products are usually formed by an extruder. Silicone rubber extrusion is generally used for the manufacture of hoses, ropes, complex profiles, and cross-section parts, often quite long, often multi-layered components, as well as rods, oven seals, cables, wire insulation, gaskets, seals Wait.

Silicone tubing is widely used in medical and mechanical equipment. It can also be used as a buffer for packaging materials.

The process uses an HCR compound with a catalyst, which is prefabricated into strips or blocks. The preform is then fed into a screw extruder that forces the compound through a hardened steel die with a pattern of cuts. The shaped silicone then passes through a heated chamber on a conveyor belt and is cured in a continuous pull oven.

The main challenge for manufacturers using this technology is how to select the appropriate grade of silicone rubber and adapted catalyst system to perform optimally in a specific mechanical, temperature, and speed-controlled process and to get the final product to specification, Tolerance standards, and compliance with regulatory standards.

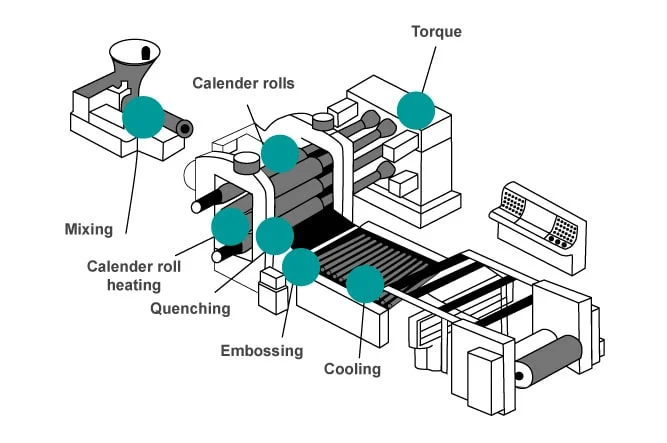

Silicone Rubber Calendering

Calendering is a mechanical process that involves compressing and smoothing the material in a continuous fashion by moving the sheet through pairs of heated rollers. These sets of double or multiple layers of hard steel rolls are called calendars. They are pressure adjusted to produce a predetermined and uniform thickness, surface finish, and texture of silicone rubber which can be glossy, matte, smooth, adhesive or embossed, etc.

The raw material, usually HCR, which determines the mechanical properties of the finished product, is previously heat softened or extruded and then forced through arrayed cylindrical rolls. The calendering process compresses the uncured silicone preform into a continuous silicone sheet. Silicones can then be pressed onto various substrates such as release liners or bonded to various fabrics, glass, plastics, and more.

The main advantages of calendering processing include

- Large-volume, continuous processing of high-quality products

- Freestanding sheets (unsupported) delivered in a protective lining or products combined with other materials, including organic or man-made fabrics (polyamide, viscose, polyester, etc.), glass, plastic, etc.

- There are almost endless applications ranging from liners for construction, household products, apparel, decorations, food contact products, industrial conveyor belts, autoclavable products for medical applications, and more.

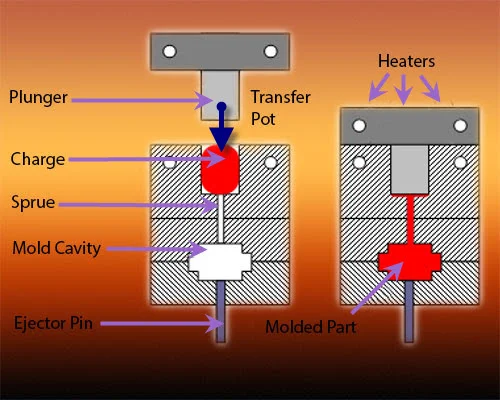

Silicone Rubber Transfer Molding

Transfer molding is similar to compression molding in several respects. It uses HCR, which is pressed from an auxiliary chamber (called a transfer tank) into a closed pressurized mold system that incorporates a heated vessel above the mold, driven using a piston Silicone rubber is filled with a unique gate and runner system that can move relatively hard materials into the mold before heating. The silicone rubber transfer molding process is ideal for manufacturing high-precision silicone molded parts, and for “stacking” with other materials to enable the molding of complex geometries. The combination of HCR and transfer molding processes can produce high-quality parts, providing design flexibility and shorter production cycles.

Transfer molding differs from compression molding in that the mold is completely closed rather than split into two parts. For this reason, it also differs from injection molding in that higher pressures are required to fill the mold. This also allows transfer molding to accept added fibers or matrix in its outer layer to produce custom-reinforced parts.

The main advantages of transfer molding processing

- Reduced tooling costs

- Uniform, accurate, and more consistent parts compared to compression molding due to the one-piece mold and high dimensional tolerance

- Efficient and agile capacity for accepting different reinforcement fibers pre-positioned in the mold, including glass, carbon, and aramid, as well as natural plant fibers.