Choosing the right silicone isn’t just about color or softness—it determines how your keypad performs, ages, and survives its environment.

Silicone keypads are made using different materials and grades based on flexibility, durability, regulatory compliance, and resistance to heat, chemicals, or UV exposure.

I’ve worked with everything from consumer electronics to industrial machinery. Each device has different needs—and picking the right silicone is one of the most critical design decisions. Here’s a breakdown of what’s available and how to choose wisely.

What types of silicone are used in keypad manufacturing?

There’s no one-size-fits-all silicone. The type you select changes how the keypad feels, wears, and performs.

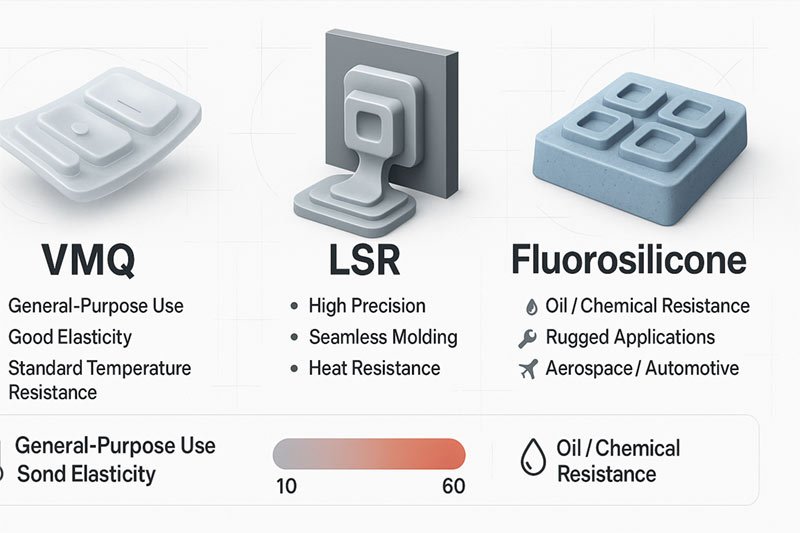

The most common silicone types for keypads are VMQ, LSR, and fluorosilicone. Each has specific benefits based on usage and environment.

Here’s how the most used types stack up:

1. VMQ (Methyl Vinyl Silicone Rubber)

This is the standard solid silicone rubber used for compression-molded keypads. It offers good flexibility, thermal stability, and moldability. Ideal for consumer and light industrial applications.

2. LSR (Liquid Silicone Rubber)

LSR is injected into molds and is ideal for high-precision or automated production. It offers excellent transparency, repeatability, and fast curing times.

3. FVMQ (Fluorosilicone Rubber)

This grade is chosen when resistance to fuels, oils, or harsh chemicals is critical—used in automotive, aerospace, and ruggedized electronics.

| Type | Best Use Cases | Key Features |

|---|---|---|

| VMQ | General, consumer, medical | Flexible, cost-effective |

| LSR | Precision devices, wearables | Clean, transparent, high consistency |

| FVMQ | Automotive, chemical exposure | Superior chemical resistance |

The right type makes all the difference between a keypad that works—and one that fails too soon.

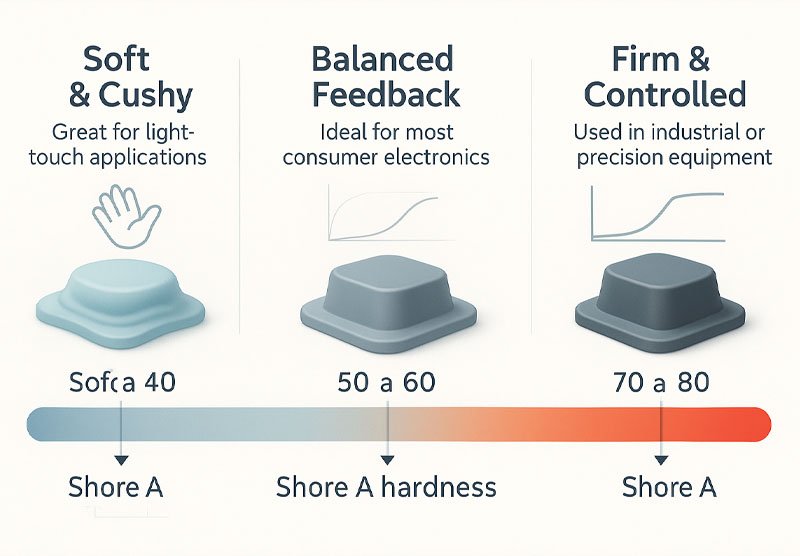

How do silicone hardness levels affect keypad performance?

Hardness controls feel, feedback, and flexibility. It’s not about strength—it’s about how it reacts under pressure.

Silicone hardness, measured in Shore A, ranges from 30 to 80 for keypads. Lower values give soft, cushy keys; higher values give firm, controlled feedback.

For keypads, we typically work in the 30–70 Shore A range. Here’s how to decide:

- Shore A 30–40: Soft and flexible. Ideal for baby products or wearables.

- Shore A 50–60: Balanced feedback. Common in remote controls or consumer devices.

- Shore A 70–80: Rigid and durable. Great for industrial and outdoor use.

| Shore A Rating | Feel | Common Applications |

|---|---|---|

| 30–40 | Soft, cushiony | Baby products, smartwatches |

| 50–60 | Balanced | Electronics, household devices |

| 70–80 | Firm, rigid | Industrial, vehicle control pads |

We help our clients choose based on the user’s touch expectations and environmental stress levels.

What are the benefits of medical and food-grade silicone?

Some devices need more than comfort—they must be safe and certified for contact.

Medical and food-grade silicone are ultra-pure materials certified to meet FDA, USP Class VI, or LFGB standards. These grades are hypoallergenic, non-toxic, and easy to sterilize.

These grades are required in baby products, medical devices, or anything that may contact skin or food.

- Medical-grade silicone is used in monitors, defibrillators, and hospital controls. It resists cleaning chemicals and body fluids.

- Food-grade silicone is common in baby bottle warmers, blenders, and teething devices. It resists high heat and is BPA-free.

Certifications often include:

- FDA 21 CFR 177.2600

- USP Class VI

- LFGB (for Europe)

| Grade Type | Application Areas | Certifications |

|---|---|---|

| Medical-Grade | Healthcare, wearables | USP Class VI, ISO 10993 |

| Food-Grade | Kitchenware, baby items | FDA 21 CFR, LFGB, BPA-free |

Using the right grade keeps your product safe—and compliant with international regulations.

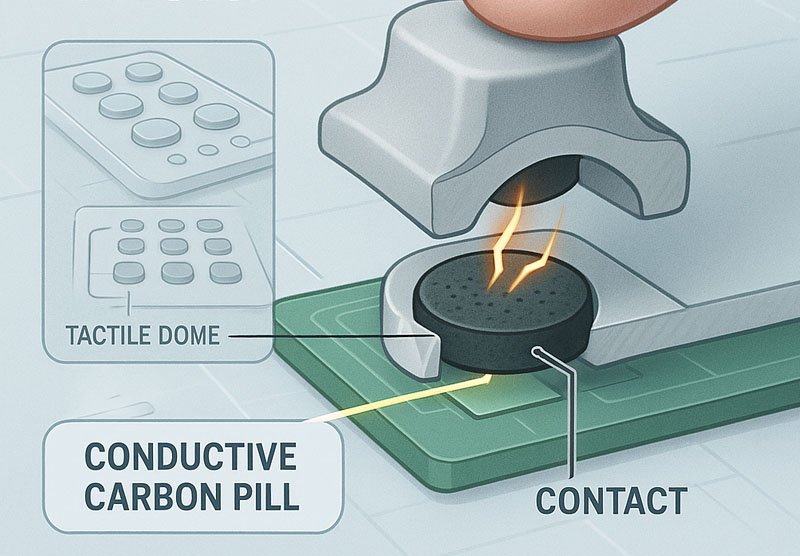

How do additives modify silicone performance?

Additives can enhance strength, conductivity, flame resistance, or even color. Silicone is flexible in more ways than one.

Additives like conductive carbon, color pigments, UV stabilizers, and flame retardants help tailor the silicone to your application needs.

We often modify base silicone with the following:

- Carbon or silver powder for conductive pads (switching function)

- Pigments for brand colors or coding

- UV inhibitors for outdoor devices

- Flame retardants to meet UL 94 V-0 fire ratings

These additives are mixed in during milling or injection and thoroughly tested for uniformity.

| Additive Type | Purpose |

|---|---|

| Conductive Filler | Enables electrical switching |

| Flame Retardant | Meets fire safety standards |

| UV Stabilizer | Prevents fading or cracking |

| Pigments | Matches brand or user interface |

Custom silicone is more than the base polymer—additives turn it into a tailored material.

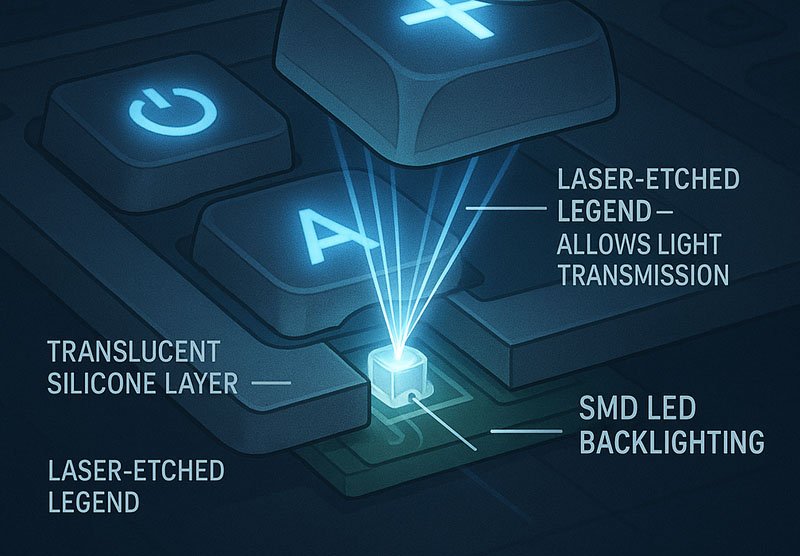

What role does transparency or opacity play?

Visibility and backlighting compatibility often depend on how light interacts with the silicone.

Silicone can be fully opaque, translucent, or transparent depending on the design need. Backlit keypads use laser-etched legends with translucent silicone.

Transparent or translucent silicone is often used in:

- Backlit control panels

- Night-use devices

- Aesthetic design elements

We choose silicone clarity based on lighting specs. In some cases, we use multi-layer molding—translucent silicone for light areas and opaque silicone for the outer shell.

| Opacity Level | Application Example |

|---|---|

| Transparent | Smartwatch buttons |

| Translucent | Backlit dashboard keypads |

| Opaque | Industrial keypads, non-lit use |

Designing for light transmission must be considered during material selection—not after tooling.

How does material choice impact environmental resistance?

Some devices live in the harshest conditions—outdoor, marine, or chemical environments.

Material choice directly affects the keypad’s resistance to UV rays, water, chemicals, and extreme temperatures. FVMQ and special-coated VMQ excel in these environments.

For rugged devices, we use:

- FVMQ silicone for chemical and oil resistance

- VMQ with UV-resistant coating for outdoor use

- Hydrophobic coatings for moisture protection

- Thermal-grade silicone for extreme cold or heat

We match the material’s properties with the expected environment to avoid swelling, cracking, or fading.

| Condition | Recommended Silicone Type |

|---|---|

| UV Exposure | UV-stabilized VMQ or LSR |

| Fuel/Chemicals | FVMQ |

| Salt Water | Coated VMQ or FVMQ |

| Extreme Heat/Cold | Thermal-grade silicone |

This is where experience matters most—we’ve seen what fails in the field and build for success.

Conclusion

Silicone keypads can be customized in material, grade, hardness, and additives to match each industry’s needs. Choosing the right combination ensures lasting performance, safety, and satisfaction.