Silicone keypads don’t just need to feel good—they need to look good, even in the dark.

From medical devices used on night shifts to high-end gaming gear glowing like a spaceship console, backlighting isn’t a luxury anymore—it’s a feature users expect.

But not all backlighting is created equal.

You can backlight silicone keypads using EL films, LEDs, fiber optics, or light guides—but for most OEM applications, LED + laser-etching delivers the best cost-to-performance ratio.

It’s durable, customizable, energy-efficient, and compatible with all common keypad materials and coatings.

Let me walk you through the bright and dim sides of each method—based on what we’ve seen in our 10,000 m² production floor and 13+ years of B2B projects across industries.

Why is backlighting so important in today’s products?

Backlit keypads serve two purposes:

- Functionality – If users can’t see the keys, they can’t use the product. Medical, military, and automotive markets require visibility in low-light settings.

- Aesthetics – Let’s be honest—glowing keys sell. They look modern, sharp, and give your product a premium edge.

Backlighting isn’t just for phones and keyboards anymore.

We’ve built light-up silicone keypads for everything from hospital ventilators to smart grills.

If you’re not offering it, your competitors will.

What are the main backlighting methods for silicone keypads?

Here’s the quick rundown of your backlighting options:

- LEDs (Light Emitting Diodes) – The most common and flexible solution. Direct or indirect light.

- EL (Electroluminescent) Film – Thin, even light source but shorter lifespan.

- Fiber Optic Lighting – High-end look, complex and expensive.

- Light Guide Films (LGF) – Efficient light distribution with minimal LEDs.

- Phosphorescent Pigments – Glow-in-the-dark effect without power.

Let’s dig into the pros and cons of each.

LED backlighting: the go-to solution for most silicone keypad projects

If you asked me to choose one backlighting option for 90% of applications, I’d go with LEDs.

Why? Simple: they’re cheap, bright, small, and durable.

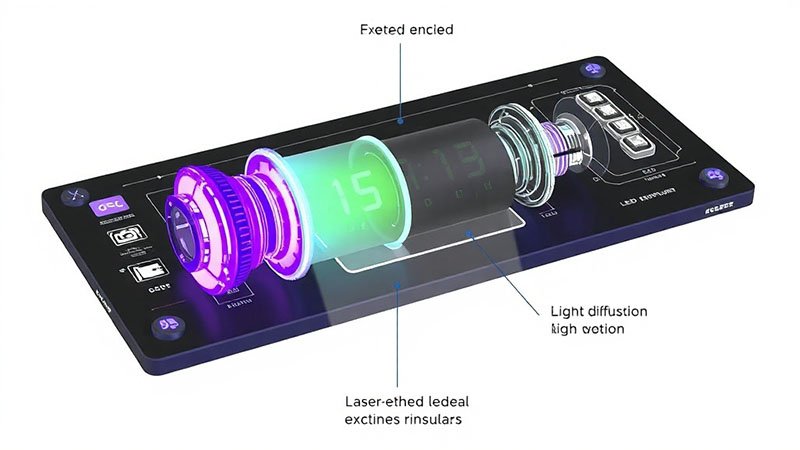

We embed surface-mount LEDs beneath or around the keypad. Then we laser-etch the legends or icons so light shines through only the characters.

Pros:

- Long lifespan (up to 100,000 hours)

- Supports multiple colors and RGB effects

- Works with laser-etching and translucent silicone

- Low power consumption

Cons:

- Needs careful placement for even lighting

- Can cause hotspots if not designed properly

Our engineers use light diffusion simulations to avoid bright spots and shadows. Want clean, even glow? Use a light guide film—I’ll explain next.

Light Guide Films (LGF): efficient and elegant for thin designs

LGFs are clear polycarbonate films with micro-lens patterns that guide light from LEDs across the keypad.

Think of them like optical highways for photons.

They’re ideal when you want to minimize the number of LEDs without sacrificing brightness.

Pros:

- Ultra-slim (good for handhelds)

- Reduces number of LEDs needed

- Provides very even backlighting

- Great for rubber dome or metal dome keypads

Cons:

- Slightly higher tooling and design cost

- Needs precise alignment with LED placement

If you’re building a compact device where battery life and internal space are both precious, LGF is a strong contender.

Electroluminescent (EL) film: even lighting with a shorter life

EL film is like a glow-in-the-dark pancake made from phosphor and electrodes. When you apply current, it glows.

It’s beautifully uniform—no hotspots, no shadows.

Pros:

- Very thin (under 0.2 mm)

- Incredibly even light

- Low heat output

Cons:

- Shorter lifespan (3,000–8,000 hours)

- Requires AC inverter (adds cost and complexity)

- Not as bright as LEDs

We used to build EL-backed panels for military radios a few years ago. These days, most customers go LED for better longevity and brightness.

Fiber optic lighting: premium, niche, and complex

This one’s for the high rollers.

Fiber optics transmit light from a central LED source via bundled strands. They can snake through complex layouts and still keep brightness consistent.

Pros:

- Can light multiple keys with a single LED

- Flexible routing

- Great for custom-shaped keypads or curves

Cons:

- High cost

- Requires careful engineering

- Not suitable for thin-profile designs

We recommend fiber optics only for very specific applications—like aviation or luxury automotive dashboards—where every detail matters.

Glow-in-the-dark pigments: the power-free option

No power? No problem.

We can mix phosphorescent powder directly into the silicone to give it a gentle afterglow.

It charges under ambient light and emits a soft glow for several hours.

Pros:

- No electricity needed

- Simple and inexpensive

- Still visible during power outages

Cons:

- Not very bright

- Fades over time (usually within 4–6 hours)

- Color choices limited (typically green or blue)

Great for emergency equipment or outdoor devices, but not suitable for products where brightness and sharp detail are important.

How to choose the right backlighting setup?

Here’s my 3-step framework I give all new customers:

- Define the use case Night use? Harsh environments? Is battery life critical?

- Consider your aesthetics Do you want glowing legends only? Or the whole key? Single color or RGB?

- Match budget and tech EL is elegant but short-lived. Fiber is flashy but pricey. LED + LGF is your sweet spot for performance and cost.

And always, always consider laser etching. It turns a functional backlight into a professional-grade interface.

Can you combine coatings with backlighting?

Yes—and you should.

We often spray silicone keypads with PU coatings, then laser-etch them to reveal legends beneath.

This gives a crisp, high-contrast backlit icon—and durability that lasts.

Want anti-microbial or anti-smudge on top? No problem. We layer coatings in sequence and cure them under heat or UV, depending on your product spec.

The only catch: you need precise alignment and masking during production.

Luckily, we’ve got that down to a science.

FAQs on silicone keypad backlighting

Q1. Can I have multi-color backlighting?

Yes. RGB LEDs can cycle or display fixed colors per key. Just be sure your PCB supports that logic.

Q2. Is backlighting waterproof?

It can be. We design keypads to IP67 or higher by sealing the light windows and gaskets properly.

Q3. Will laser etching wear off over time?

No. Laser removes coating, not silicone. The legend is permanent and only fails if the keypad is physically damaged.

Q4. Can Ruiyang provide samples with different lighting methods?

Absolutely. We ship sample kits to clients in the U.S., Canada, and EU regularly—just cover shipping. Contact support@rysilicone.com.

Conclusion

The right backlighting setup does more than illuminate keys—it elevates your whole product.

Choose wisely, blend smart coatings, and your keypad won’t just function well—it’ll glow with purpose and style.

Let there be light.

And let it be evenly diffused, color-accurate, power-efficient light—with a laser-etched logo that makes your brand shine.