When silicone keypads fade, crack, or corrode, it’s usually not wear and tear—it’s chemistry or sunlight. These invisible threats can destroy functionality.

Silicone keypads resist chemicals and UV rays through material composition, protective coatings, and design choices that prevent degradation in harsh environments.

I’ve worked on silicone keypads for outdoor controls and lab instruments. If you want yours to last, you need to know how they stand up to chemical exposure and UV damage.

What Chemicals Can Damage Silicone Keypads?

Not all exposure is obvious. Even skin oils can degrade silicone over time.

Silicone keypads are vulnerable to strong acids, bases, solvents, and certain oils unless protected with coatings or formulated with resistant silicone types.

Here are common threats:

| Chemical Type | Risk Level | Common Sources |

|---|---|---|

| Strong Acids | High | Cleaners, lab spills |

| Alkalis | High | Industrial soap, degreasers |

| Organic Solvents | Moderate–High | Alcohol, acetone |

| Oils and Grease | Moderate | Skin contact, machines |

| Water | Low | Unless carrying other agents |

The problem isn’t always immediate. Chemicals can slowly degrade surface texture, change colors, or weaken key responsiveness. That’s why I recommend testing keypads with all substances they might encounter.

How is Chemical Resistance Achieved?

It’s not just the silicone—it’s what’s on top.

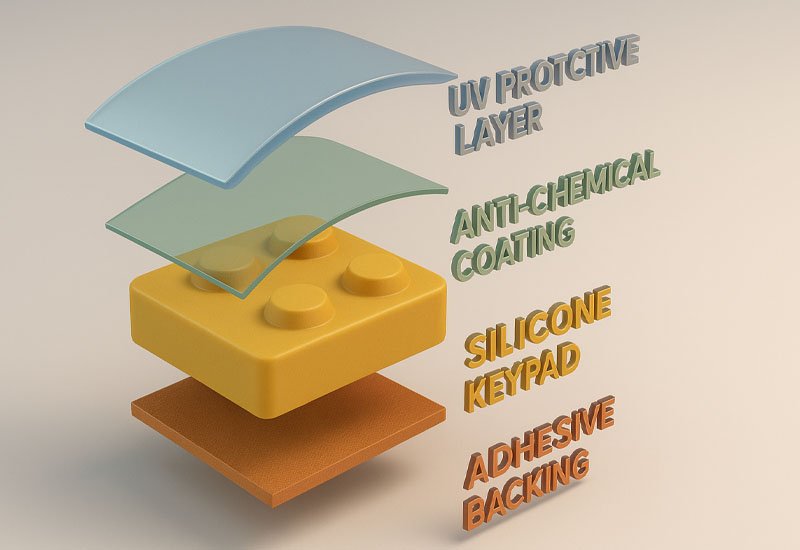

Chemical resistance is achieved using high-grade silicone formulations and protective coatings like polyurethane, fluorosilicone, or Parylene.

Key methods include:

- Fluorosilicone: Silicone mixed with fluorine for chemical resistance

- PU (Polyurethane) Coating: Adds an extra shield over the surface

- Parylene Coating: Conformal vapor-applied barrier for harsh environments

- Laser Etching with Hard Coating: Protects legends from wearing off

In a project for a food processing plant, I used fluorosilicone keypads to withstand daily alkaline cleaning. They performed flawlessly for years.

Choose the coating based on your chemical exposure profile. Some coatings alter tactile feel, so always prototype.

How Does UV Light Damage Silicone Keypads?

Sunlight isn’t soft. It breaks bonds, even in durable materials.

UV light degrades silicone keypads by breaking down polymer chains, causing yellowing, cracking, and loss of flexibility over time.

Without protection, silicone left in direct sun can:

- Fade or discolor (especially with non-UV-stable pigments)

- Lose elasticity and become brittle

- Show surface cracking

UV degradation doesn’t always look dramatic—it can start with a slight chalky texture. That’s often the first sign of surface oxidation.

I had to redesign an outdoor keypad once because after six months of sun, the buttons turned from blue to grey and lost responsiveness. Lesson learned: use UV-stabilized compounds.

How is UV Resistance Improved?

The best defense is built-in and layered.

UV resistance is improved using UV-stabilized silicone, protective coatings, and pigment additives that absorb or reflect ultraviolet rays.

There are three main methods:

- UV-Stable Pigments: Colorants that resist fading

- UV Absorbers: Additives in silicone that block UV penetration

- Surface Coatings: PU or acrylic sprays that shield from light

For critical outdoor uses, I combine UV-stabilized silicone with a PU matte coating. It preserves both function and appearance.

Ensure your supplier tests keypads under simulated UV exposure (e.g., xenon arc lamp testing) to confirm resistance over time.

Which Industries Rely on High Chemical and UV Resistance?

Exposure isn’t just likely—it’s guaranteed in some fields.

Industries like medical, food processing, automotive, and outdoor electronics rely on chemical and UV-resistant silicone keypads to ensure long-term reliability.

| Industry | Exposure Type | Why Resistance Is Critical |

|---|---|---|

| Medical | Alcohol, sterilizers | Hygiene and chemical contact |

| Food Processing | Alkali cleaners, oils | Daily wash-downs |

| Automotive | UV, hand oils, cleaners | Sunlight and frequent use |

| Marine/Outdoor | UV, salt spray, rain | Harsh weather conditions |

If your product will live in the sun or be cleaned every day, chemical and UV resistance must be part of your design spec—not an afterthought.

How to Specify Resistance in Your Design?

If you don’t ask for it, you won’t get it.

To ensure chemical and UV resistance, specify required coatings, materials, and test standards in your product documentation and supplier discussions.

Checklist for your spec sheet:

- Use fluorosilicone or UV-stable silicone blend

- Request PU or Parylene coatings

- Ask for pigment UV stability test data

- Include resistance test standards (e.g., ASTM G154, ISO 4892-2)

- Demand real-use chemical exposure testing

Working closely with your supplier from the start prevents failure down the line. I always include a test matrix with all expected environmental exposures.

Conclusion

Silicone keypads can resist chemicals and UV—with the right materials, coatings, and specifications. Durability is designed, not assumed.