Frustrated with surfaces that trap sticky glue, burnt food, or chemical residues? Cleaning becomes a nightmare. Worse—damaged products, delayed production, and wasted time. Traditional mats just can’t handle it.

Silicone mats use advanced non-stick surface technologies to resist adhesion from glue, food, and chemicals. Their hydrophobic and oleophobic properties repel sticky substances, making them perfect for industrial, culinary, and crafting applications. Combined with heat resistance and easy cleaning, they’re the ideal reusable surface solution.

Let’s break down the science, use cases, and why your brand should be offering these to your customers ASAP.

What Makes Silicone Non-Stick by Nature?

Unlike plastics or metals, silicone has a low surface energy, meaning adhesives and residues struggle to bond with it. On a molecular level, silicone’s inert, flexible chains repel both water-based and oil-based substances.

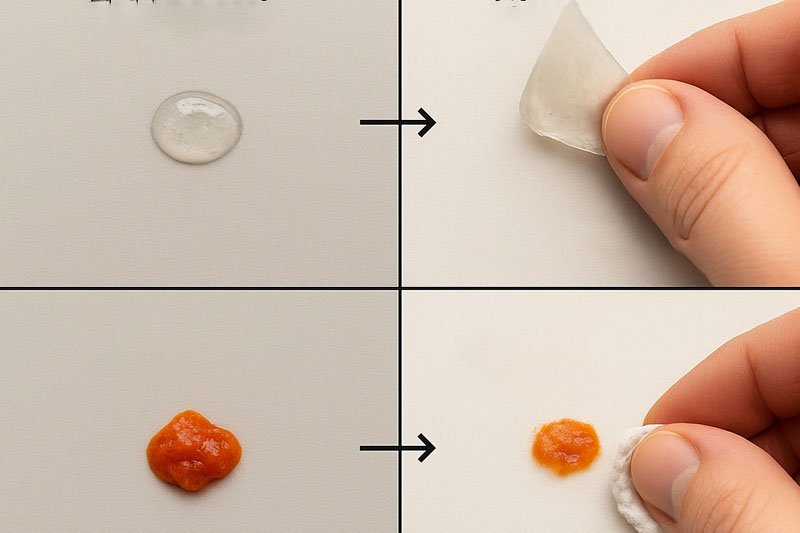

The result? Most glues, baked-on sugars, or spilled chemicals just sit on the surface—waiting to be wiped off. No scraping. No residue.

- Hydrophobic: Repels water and water-based adhesives.

- Oleophobic: Repels oils, grease, and synthetic glues.

Where Non-Stick Silicone Mats Shine

Non-stick mats are used across industries. Here’s where they make life cleaner and easier:

- Baking & Cooking: Pastry, dough, caramel, and chocolate slide right off.

- Crafts & DIY: Resin, hot glue, epoxy, and acrylics don’t bond.

- Electronics & Assembly: Silicone mats resist flux, solder residue, and adhesives.

- Chemical Labs: Acids, solvents, and lab spills won’t etch or cling to the surface.

Customers love the convenience—and your brand earns points for delivering a smart, long-lasting solution.

How Do We Enhance the Non-Stick Properties of Silicone Mats?

While silicone is naturally non-stick, we take it a step further:

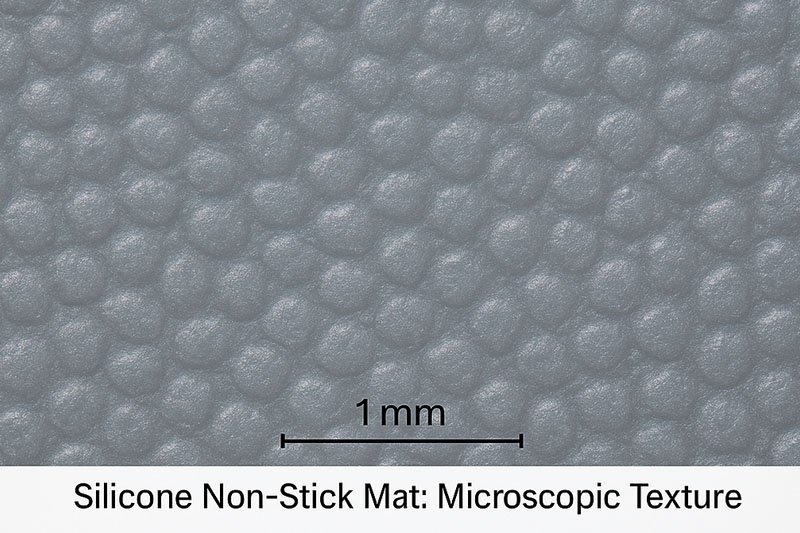

- Surface Texture Engineering Smooth or lightly textured surfaces reduce contact area, enhancing release performance. Think of it like Teflon but more flexible and eco-friendly.

- Plasma Treatment (Optional) Some specialty mats undergo plasma or fluoropolymer treatments for extreme non-stick applications, such as industrial or aerospace.

- Additive-Free Formulation We don’t coat the surface with anything that peels or degrades. The non-stick property is built into the silicone itself for long-term reliability.

How Easy Are Non-Stick Mats to Clean?

Here’s where silicone mats blow the competition away:

- Wipe & Go: Most spills can be wiped off with a damp cloth.

- Dishwasher Safe: Ideal for kitchen applications.

- Resistant to Staining: Even colored resins or spices won’t cling.

This reusability reduces waste and improves ROI for your customers. No more disposable liners or paper waste—hello eco-friendly solution.

Customization Options for Non-Stick Silicone Mats

Just like our heat-resistant or anti-slip variants, non-stick silicone mats are fully customizable:

- Size & Shape: Custom cut to fit your workbench, baking tray, or assembly line.

- Color Options: Branded colors, color-coded work zones, or classic translucent options.

- Logos & Graphics: Embossed or printed for brand visibility.

- Dual-Surface Texturing: One smooth side, one textured—for versatile use cases.

This level of customization allows you to offer highly specific solutions to niche markets like bakers, crafters, labs, and tech assembly lines.

The Manufacturing Process Behind Non-Stick Silicone Mats

Here’s how we turn raw silicone into your perfect sticky-proof mat:

- Raw Silicone Selection: We use platinum-cured food-grade or industrial-grade silicone based on the end-use.

- Molding Stage: Compression or injection molding defines the shape, surface texture, and dimensions.

- Surface Finishing: We apply optional plasma treatments or polish the surface to a perfect non-stick finish.

- Logo & Branding Application: Logos are added via embossing or screen-printing methods that don’t interfere with surface function.

- Inspection: Each mat undergoes non-stick performance testing—glue, oil, or sugar-based testing based on use case.

- Packing & Delivery: Each mat is packed clean, flat, and ready for B2B shipment.

What Safety and Quality Standards Should You Expect?

We know that John White and his peers care about certifications—especially when dealing with food or chemical applications.

Here’s what we deliver:

- FDA & LFGB Certification: Food-safe and non-toxic.

- REACH & RoHS Compliance: No hazardous materials—safe for humans and the environment.

- ISO 9001: Quality management for every stage of production.

- Durability Testing: Abrasion, chemical resistance, and heat cycle tests ensure your mat performs for years.

All test reports are provided with each batch to ensure complete transparency. No shady documents—just real quality, every time.

Comparing Silicone to Other Non-Stick Materials

Let’s be honest—there are alternatives out there, but none quite like silicone.

| Material | Temp Resistance | Flexibility | Reusability | Toxic-Free | Non-Stick Power |

|---|---|---|---|---|---|

| Teflon Coating | Medium | Low | Moderate | Debatable | High (short term) |

| Plastic Mats | Low | Medium | Low | No | Low |

| Wax Paper | Very Low | High | Single Use | Yes | Medium |

| Silicone Mat | High | High | Very High | Yes | Very High |

Silicone wins in nearly every category—especially in long-term use and safety.

FAQs About Non-Stick Silicone Mats

Q: Will hot glue really not stick to the mat?

A: Correct—once cooled, the glue peels off cleanly without residue.

Q: Can the non-stick surface wear off over time?

A: No. Because it’s not a coating but an inherent property of the silicone, it stays effective for years.

Q: Can I use the same mat for food and glue crafts?

A: We recommend separate mats for food and industrial use to avoid cross-contamination.

Q: What are the thickness options?

A: 1 mm to 6 mm are common. We suggest thicker mats for heavy-duty crafting or workstation use.

Q: What’s the MOQ?

A: As usual, 500 pcs—but let’s talk if you need flexibility.

Conclusion

Non-stick silicone mats are a smart, versatile solution for industries struggling with sticky messes—from kitchens to electronics labs. With advanced surface technology, high durability, and full customization, they offer both function and branding power.