Choosing the wrong silicone sheet hardness can lead to product failures, poor performance, or customer complaints.

Silicone sheet durometer ratings measure the hardness and flexibility of the material, helping manufacturers choose the right silicone for specific applications.

Silicone sheet hardness affects flexibility, performance, and safety. I’ve learned the hard way that choosing the wrong Shore hardness can cost time and money. Let’s look deeper into what these numbers actually mean.

What is Durometer in Silicone Sheets?

Ever bought a silicone sheet and felt confused by the Shore A number on the spec sheet?

Durometer is a measure of how hard or soft silicone is, using a Shore hardness scale—commonly Shore A for flexible materials.

The term durometer refers to both the tool used and the measurement result. Most silicone sheets are rated on the Shore A scale, which ranges from 10 (very soft) to 90 (very hard). A lower durometer means more flexibility and softness, while a higher durometer offers more rigidity and less compression.

Here’s a basic table showing how Shore A ratings translate into feel and function:

| Shore A Rating | Texture Feel | Common Use Cases |

|---|---|---|

| 10–30 | Gel-like, very soft | Baby products, medical cushioning |

| 40–50 | Soft, flexible | Gaskets, seals, moderate compression |

| 60–70 | Firm but flexible | Industrial sheets, insulation |

| 80–90 | Hard, rigid | Structural uses, heavy-duty sealing |

Each application requires different mechanical properties. Understanding the durometer rating helps me choose silicone sheets that perform well and last longer in their intended use.

How is Shore Hardness Measured?

I used to think durometer ratings were just estimates, but there’s real science behind them.

Shore hardness is measured by pressing a standardized indenter into the silicone surface and recording the resistance force.

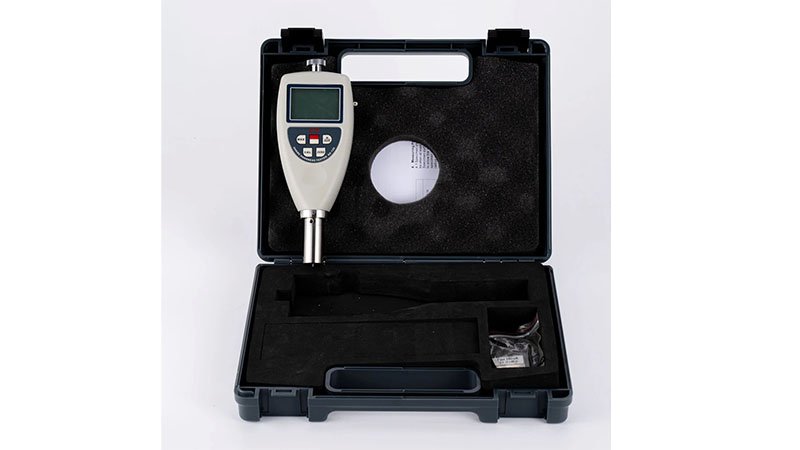

In testing, a durometer tool applies force through a spring-loaded indenter. For Shore A silicone, the device uses a blunt, rounded needle. The result is a number from 0 to 100, which reflects how much the material resists penetration.

The testing must follow ASTM D2240 standards. It’s done at controlled room temperatures with samples of a specific thickness—usually around 6 mm for accuracy. Even slight changes in thickness, surface texture, or temperature can impact readings.

In my experience, suppliers who regularly calibrate their measuring equipment tend to deliver more consistent silicone products. When accuracy matters, always ask for the testing method and certification details.

Why Does Durometer Matter for Silicone Performance?

I once chose the wrong Shore hardness for a food-grade project. The material tore too easily under pressure. Lesson learned.

Durometer affects silicone’s flexibility, compression resistance, and long-term durability under stress.

Silicone used in baby products must be soft and safe for gums. But industrial gaskets need enough firmness to seal against pressure. The durometer determines how well silicone resists deformation, tearing, and wear.

Here’s how different Shore A ratings behave:

- Soft silicone (20–40): Highly compressible, absorbs shock well, good for gentle contact.

- Medium silicone (50–60): Balances flexibility and strength, often used in automotive and kitchen applications.

- Hard silicone (70–90): Best for mechanical stability, tough environments, and chemical resistance.

I always match the Shore A rating to the application’s stress level and temperature range. The wrong durometer can cause leaks, breakage, or deformation over time.

Which Shore Hardness is Best for My Application?

Clients often ask, “What hardness should I choose?” My answer: it depends on what you’re making.

The best Shore hardness depends on the product’s function—soft for comfort, firm for sealing, and hard for support.

Let’s break it down:

| Application | Ideal Shore A | Why It Works |

|---|---|---|

| Baby Teethers, Pacifiers | 20–30 | Soft, gentle on gums |

| Gaskets, Seals | 50–70 | Flexible yet pressure-resistant |

| Industrial Pads | 60–80 | Impact and heat resistance |

| Baking Mats, Cookware | 40–60 | Flexible for handling, withstands heat |

| Machine Vibration Pads | 70–90 | Rigid for absorbing repetitive shock |

I once worked with a baby care brand where we tested both 20A and 40A silicone for teething rings. The 20A passed better in user feedback. It felt softer and more comforting to babies. Always test if unsure.

Can Durometer Change Over Time?

One mistake I made early on was not considering how silicone ages under stress.

Yes, silicone durometer can increase slightly over time due to compression set, heat exposure, or aging.

Silicone is stable, but not immune to environmental effects. Continuous pressure, UV exposure, and high temperatures can harden the material over time. This is called durometer drift or hardening.

High-quality silicone resists this better, especially those with additives for heat or UV resistance. For baby products, food-grade and platinum-cured silicone hold up well. For industrial applications, I always ask about long-term test data before choosing a supplier.

Here’s what affects Shore A over time:

- Compression set: Permanent deformation reduces elasticity.

- Thermal cycles: Expansion and contraction can stiffen silicone.

- Chemical exposure: Oils and solvents may change surface texture or hardness.

Understanding aging helps me plan for product lifespans and replacement intervals.

How to Choose the Right Silicone Sheet Supplier?

Not all silicone sheets are created equal—even if the specs say “60 Shore A.”

A good supplier provides certified, tested silicone with consistent Shore hardness and application support.

Choosing the right supplier affects everything from safety to customer satisfaction. I always look for:

- Material certification: FDA, LFGB, RoHS compliance

- Shore A test reports: Verified by third-party labs

- Custom cutting options: For thickness, color, and texture

- Batch consistency: Especially for baby and medical-grade uses

- Customer service: Can they recommend the right durometer?

Working with RuiYang Silicone has helped me solve many of these issues. They provide reliable durometer options, offer customization, and understand the baby product market well. Their silicone stays consistent from batch to batch, which saves me a lot of rework.

Conclusion

Understanding durometer and Shore hardness helps me choose silicone sheets that last longer and perform better.