If you’ve ever struggled to choose the right silicone sheet thickness for electrical insulation, you’re not alone.

Too thin, and you risk a short circuit. Too thick, and you’re wasting money and space.

Let’s cut through the confusion—I’ll explain the right thickness options and what they actually mean for your performance and safety.

The ideal thickness for silicone electrical insulation depends on voltage, temperature, and usage.

For low-voltage setups, 0.3mm to 1mm may suffice. For industrial or high-heat environments, 2mm–6mm or more is common. Choose based on dielectric strength, flexibility, and environmental resistance.

Stick around—I’ll break this down by use case, spec, and even cost efficiency. This isn’t just insulation, it’s an investment in uptime.

What’s the purpose of silicone sheet thickness in electrical insulation?

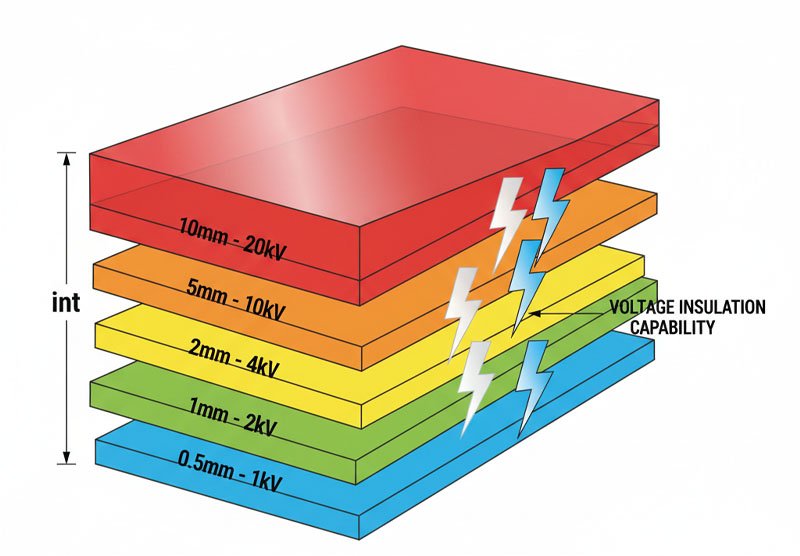

Silicone’s natural dielectric strength (typically around 20–25 kV/mm) makes it ideal for insulating against high voltage.

But not all thicknesses are created equal. In fact, overkill is a real thing.

A 0.5mm silicone sheet rated at 20kV/mm gives you 10kV of resistance.

A 3mm sheet? That’s 60kV, but it’s 6x heavier and eats up space.

So, thickness isn’t just about more protection—it’s about optimizing protection.

Use too little, and you fry your equipment. Use too much, and your enclosure doesn’t close properly.

How do you choose the right thickness based on application?

Here’s a quick cheat sheet for most common scenarios:

| Application | Suggested Thickness | Why It Works |

|---|---|---|

| Consumer Electronics | 0.3–0.8mm | Thin, flexible, still high voltage resistance |

| Automotive | 1–2mm | Heat-resistant and rugged |

| Power Distribution Panels | 3–6mm | Handles sustained high voltages |

| Outdoor/UV Exposure | 2–5mm | Extra durability, weatherproof |

| Clean Rooms / Labs | 1–3mm | Chemical resistance and easy to clean |

Need a custom thickness? We can extrude or mold to your spec. We’ve done everything from 0.2mm all the way up to 10mm for industrial clients.

What standards should your silicone insulation meet?

You don’t just need the right thickness—you need the right certifications to prove it’s safe.

Look for:

- UL 94 V-0 flame retardant rating

- RoHS compliance

- FDA grade if it’s in food-processing equipment

- IEC 60243 or equivalent for dielectric strength validation

- ISO 9001:2015 for manufacturer credibility

We test all our sheets for consistency in thickness tolerance, dielectric breakdown, and thermal endurance before they leave the factory.

Our clients care about specs—and frankly, so do we.

Can you customize silicone sheet thickness?

Absolutely.

We offer two major customization paths:

- Compression Molding – great for small batch, precise size, and specific shore hardness.

- Extrusion – ideal for continuous rolls or strips of uniform thickness.

You can specify:

- Thickness (from 0.2mm to 10mm+)

- Color (we do custom Pantone matching)

- Hardness (Shore A 10 to 80)

- Surface texture (smooth, matte, embossed)

And let’s be honest—if your supplier can’t hit your tolerance, it’s not “custom,” it’s chaos.

Is thicker always better?

Nope. Thicker silicone adds:

- Weight

- Cost

- Less flexibility

- Longer curing times

Unless you’re insulating for extreme voltages or direct heat contact, thinner is often smarter.

For example, one of our Canadian clients ordered 5mm sheets thinking “more is better”—only to find out their enclosure couldn’t close.

We retooled with 2mm, saved them $2,000, and it passed UL tests just fine.

Efficiency is the real goal—not maximum thickness.

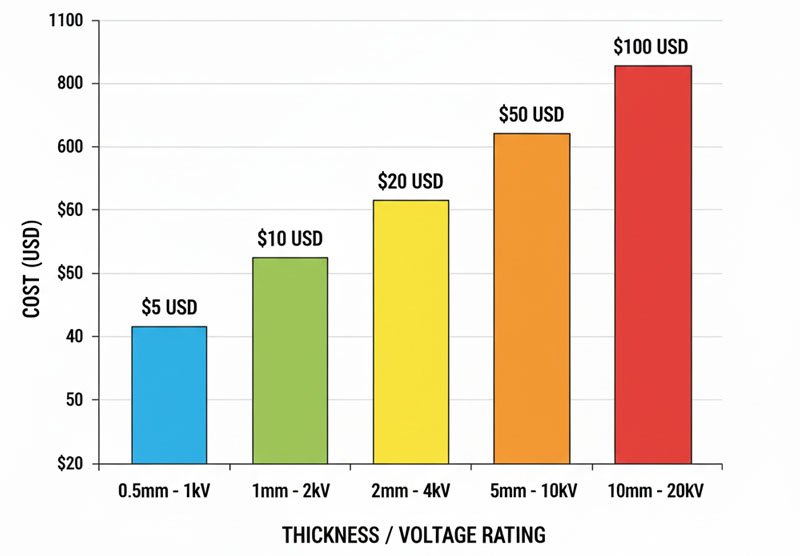

What are the cost implications of different thicknesses?

More thickness = more material = more cost. But it’s not linear.

Here’s a rough cost comparison (per m², based on standard compound):

| Thickness | Estimated Cost (USD) |

|---|---|

| 0.5mm | $4–6 |

| 1mm | $6–9 |

| 2mm | $9–12 |

| 3mm | $12–15 |

| 5mm | $17–22 |

Prices vary by volume, color compound, and certifications.

And don’t forget—custom post-processing (like adhesive backing or die-cutting) affects the bottom line.

Want a quote with your thickness spec? You know where to find me.

Conclusion

Choosing the right silicone sheet thickness isn’t just a technical decision—it’s a business one.

It impacts performance, safety, price, and even packaging.

We’ve helped thousands of customers strike the perfect balance, and we’re happy to help you do the same.

Need a sample or tech sheet? Shoot me a message at support@rysilicone.com

Let’s make sure your insulation is just right.