AirPods are everywhere—and so is the demand for stylish, protective, and branded silicone cases.

Custom silicone AirPod cases from China offer a profitable opportunity for brands looking to sell unique accessories with low MOQ, full customization, and fast turnaround times.

Whether you’re launching a new product line or adding a branded tech accessory to your collection, silicone AirPod cases offer high demand, wide design flexibility, and excellent margins. Sourcing them from China opens the door to full customization and scalable production. But it’s important to choose the right supplier, understand the process, and plan for quality control. This guide covers what you need to know.

Why Choose Silicone for AirPod Cases?

Not all AirPod cases are created equal—and material makes a big difference in user satisfaction.

Silicone is shock-resistant, flexible, durable, and offers excellent color control—making it a favorite for protective and promotional AirPod cases.

Silicone protects AirPods from drops, scratches, and dirt. It’s lightweight but tough. It feels soft in hand, grips well, and can be molded into endless shapes—from minimalist designs to cartoon characters.

Most importantly, it supports:

- Pantone color matching

- Custom molds and forms

- Logos via printing, debossing, or PVC appliqué

- Heat resistance and waterproofing

These features make it ideal not just for tech brands, but for lifestyle labels, influencers, retail chains, and even promotional campaigns.

What Can Be Customized in a Silicone AirPod Case?

Customization goes far beyond adding a logo.

You can fully customize the shape, color, texture, print method, and packaging of your AirPod case—creating a product that reflects your brand DNA.

Here’s what you can typically customize when working with a manufacturer in China:

| Feature | Customization Options |

|---|---|

| Size/Model | AirPods 1/2, AirPods 3, AirPods Pro, Pro 2 |

| Color | Exact Pantone match, gradients, two-tone |

| Shape/Form | Classic, pouch-style, character, themed |

| Logo/Branding | Silk-screen print, debossing, embossed PVC logo |

| Texture/Finish | Matte, glossy, soft-touch, textured grip |

| Accessories | Keychain ring, carabiner, lanyard, dust plug |

| Packaging | Blister pack, gift box, zip pouch, custom sleeves |

You can also request molds based on your own 3D files or collaborate with the factory’s design team to turn ideas into manufacturable products.

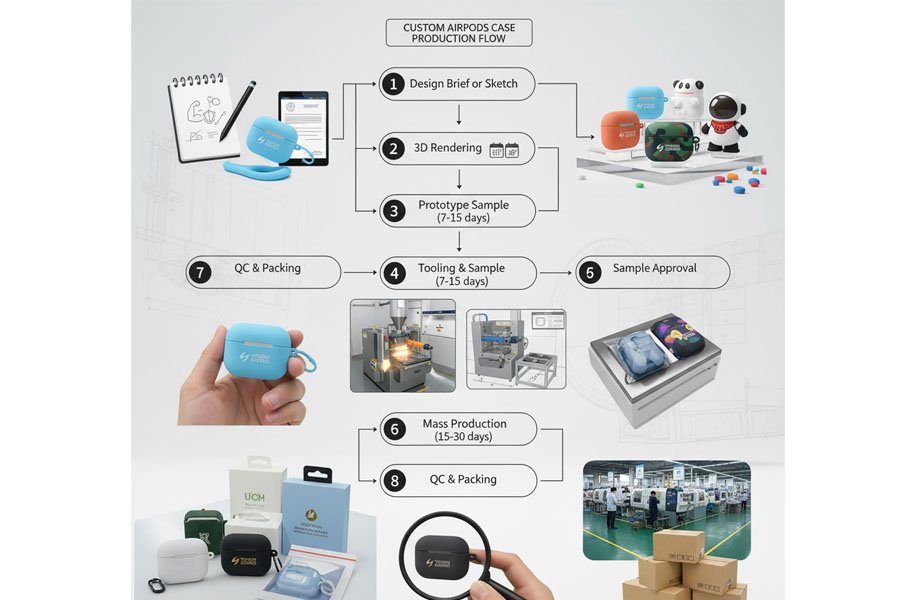

What’s the Typical Manufacturing Process?

Making a custom AirPod case involves several stages—but with a good supplier, the process is streamlined.

From concept to mass production, expect sampling, mold development, and final approval before full manufacturing begins.

Here’s a simplified overview of the process:

- Design Brief or Sketch – Provide concept, target model, and style references.

- 3D Rendering or Mold Design – Factory generates CAD file or 3D sample.

- Prototype Sample – Physical sample is made for evaluation (3–7 days).

- Tooling & Mold Creation – Custom mold is built (usually 7–15 days).

- Sample Approval – You approve the shape, fit, color, and logo.

- Mass Production – Usually takes 15–30 days, depending on quantity.

- QC & Packing – Visual inspection, logo check, packaging as required.

- Shipping – Export via air, sea, or courier.

Many suppliers support low MOQs—starting from 300–500 units per design, with affordable mold costs depending on complexity.

What to Look for in a Reliable Chinese Factory?

Choosing the right supplier makes or breaks your final product quality and timeline.

Look for factories with experience in custom silicone molding, clear communication, product certifications, and transparent sampling processes.

Here’s a checklist that helps ensure a smooth partnership:

| Checklist Item | Why It’s Important |

|---|---|

| OEM/ODM Capability | Can create your design from scratch |

| Silicone Certification | FDA, RoHS, LFGB approved for safety & quality |

| Experience with Tech Accessories | Ensures better mold fit, tolerance control |

| Logo & Printing Options | More branding flexibility |

| Sampling Support | Fast iterations before bulk |

| QC Process | Avoids issues with print, shape, and color |

| Packaging Support | Retail-ready boxes, bags, or branded pouches |

RuiYang, for example, offers full customization, low MOQ, and tooling services in-house—with over a decade of experience in silicone product development and export.

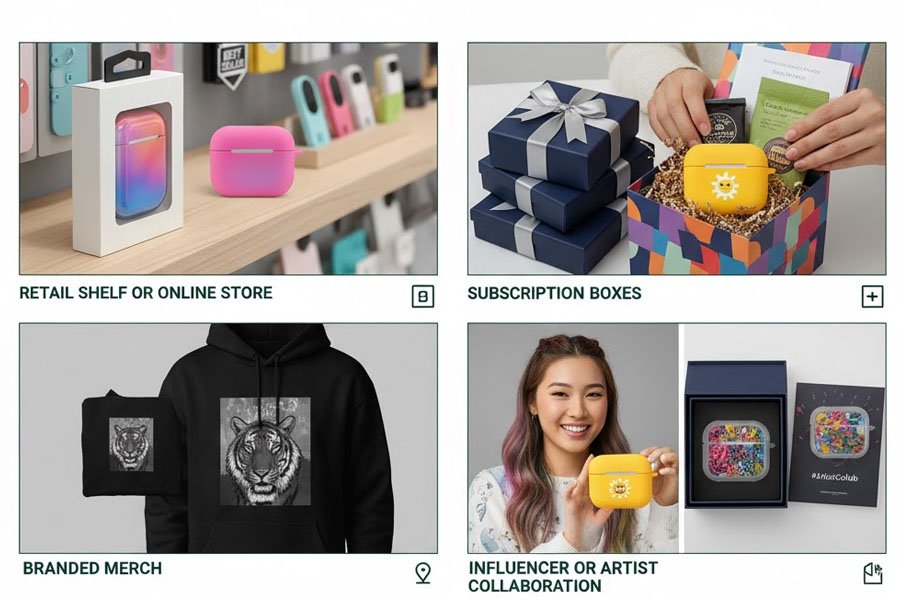

How to Position Custom AirPod Cases for Your Brand?

AirPod cases aren’t just tech accessories—they’re fashion, lifestyle, and branding opportunities.

Use your AirPod cases as standalone SKUs, add-ons, or promotional giveaways to support seasonal drops, influencer kits, or co-branded collections.

Here are a few positioning ideas:

- Retail Shelf or Online Store – Target gift buyers, teens, tech lovers

- Branded Merch – Bundle with apparel, gadgets, or creator merch

- Corporate Gifts or Events – Use logos and custom colors to align with campaigns

- Subscription Boxes – Lightweight, low-cost item with strong aesthetic impact

- Influencer or Artist Collaboration – Create limited-edition, collectible designs

Thanks to the versatility of silicone and the relatively low entry cost, AirPod cases are an easy way to expand your product catalog and boost brand visibility.

Conclusion

Custom silicone AirPod cases from China offer a high-margin, high-impact opportunity for brands in tech, fashion, or lifestyle. With the right supplier, you can create premium, retail-ready products that customers use every day.