Traditional gaskets don’t always fit odd shapes, which leads to leaks, noise, or wasted energy in HVAC systems.

Cut-to-fit silicone sheets offer a customizable sealing solution for HVAC systems, improving insulation, durability, and installation efficiency.

I’ve worked on HVAC projects where pre-made seals never quite fit. That’s when I started using cut-to-fit silicone sheets. They solved many problems in one simple move. Here’s why I now recommend them for nearly every HVAC application.

What Are Cut-to-Fit Silicone Sheets?

Ever needed a gasket or seal urgently, only to realize none of the pre-made options fit?

Cut-to-fit silicone sheets are flat silicone materials that can be trimmed to any shape or size, ideal for sealing irregular HVAC components.

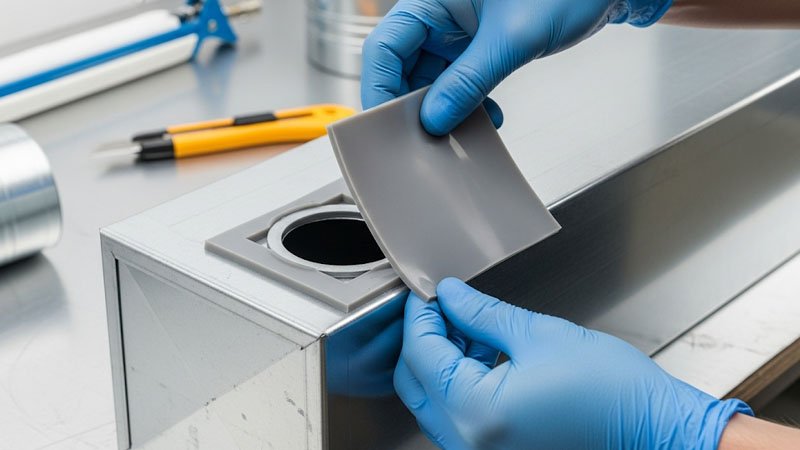

These sheets come in various thicknesses, typically from 1mm to 6mm. They can be cut on-site with scissors, blades, or die tools. That flexibility makes them perfect for sealing around air ducts, insulation panels, HVAC doors, blower housings, and custom metal enclosures.

Cut-to-fit sheets are usually made from high-temperature silicone, which resists cracking, compression, and thermal expansion. For one rooftop unit I worked on, standard foam gaskets failed after one season. We switched to a 3mm silicone sheet cut to match the panel—and it’s been going strong for three years.

Why Is Silicone Ideal for HVAC Applications?

I used to think rubber or foam was good enough—until clients started complaining about gasket failure in hot or cold weather.

Silicone is ideal for HVAC because it resists heat, cold, ozone, and compression—making it durable in extreme environments.

HVAC systems face wide temperature swings and constant vibration. Silicone’s thermal stability (–60°C to +230°C) allows it to maintain its shape and sealing ability across all seasons. It’s also non-toxic, flexible, and doesn’t degrade with ozone or UV exposure, which is critical for rooftop units and duct systems.

Key reasons I use silicone for HVAC:

- Wide temperature range: Doesn’t shrink or harden

- Long service life: Outlasts neoprene and foam

- Moisture resistance: Prevents mold and mildew

- Low compression set: Maintains seal under constant pressure

Here’s a quick performance comparison:

| Property | Silicone Sheet | Neoprene Foam | Rubber Gasket |

|---|---|---|---|

| Temp Resistance | –60°C to +230°C | –40°C to +100°C | –30°C to +120°C |

| UV/Ozone Resistance | Excellent | Moderate | Poor |

| Reusability | Yes | No | Sometimes |

| Mold Resistance | Yes | No | No |

In every tough HVAC environment I’ve seen, silicone always performs better.

How Do Cut-to-Fit Sheets Improve Installation?

We once spent hours retrofitting a pre-made seal that still leaked. That’s when we switched to cut-to-fit silicone.

Cut-to-fit sheets speed up HVAC installs by allowing on-site trimming, minimizing downtime, and eliminating the need for exact replacement parts.

When HVAC systems need repair, time is critical. Using cut-to-fit sheets means you don’t have to wait for OEM gaskets. You cut the shape on-site and install it instantly. Whether it’s for a flange, compressor panel, or duct joint, this method saves hours.

The sheets can be easily:

- Cut with box cutters or scissors

- Hole-punched for bolts or rivets

- Adhered using RTV silicone or high-temp tape

Some installers I know pre-cut a range of sizes and keep them in service kits. It’s one of the easiest ways to ensure flexibility in the field.

Are There Different Grades of Silicone Sheets for HVAC?

I once used general-purpose silicone for a rooftop unit. It hardened in winter. That’s when I learned—not all silicone is created equal.

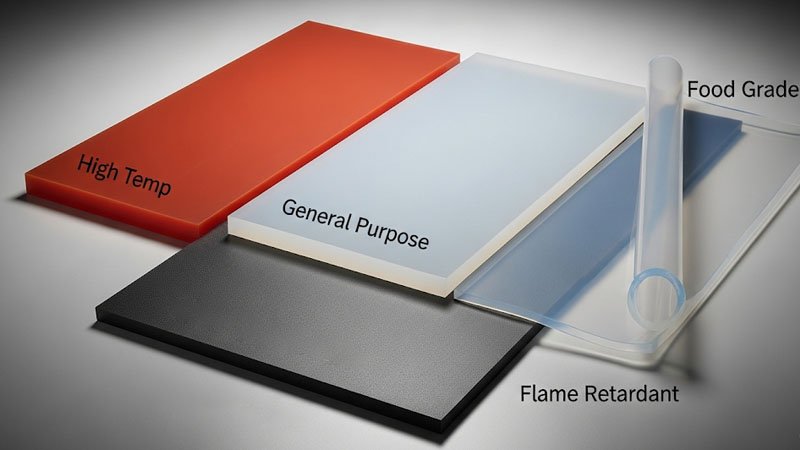

Yes, silicone sheets come in different grades such as general-purpose, high-temp, food-grade, and flame-retardant—each affecting HVAC suitability and cost.

In HVAC, the best choice depends on the location and exposure:

- High-temp silicone (red or translucent): Best for blower units, furnace seals, rooftop ducts

- Flame-retardant silicone: Essential in commercial buildings to meet fire codes

- FDA-grade silicone: Used in HVAC for clean rooms or food handling environments

- Conductive silicone: Rare but useful in EMI shielding applications

Here’s how I match silicone grades to applications:

| Application | Recommended Silicone Grade |

|---|---|

| Furnace or blower doors | High-temperature |

| Commercial building ducts | Flame-retardant (UL94V-0) |

| Cleanroom HVAC systems | FDA or medical-grade |

| Outdoor rooftop enclosures | UV and ozone-resistant grade |

Ask your supplier about the specific formulation. Some silicone sheets may look the same but behave differently under heat or pressure.

What Size and Thickness Should I Choose?

If you’re not sure which size to order, it’s easy to overspend—or under-protect.

Choose size based on surface area and thickness based on pressure resistance—most HVAC uses require 2–5mm sheets.

The most common mistake I’ve seen is using silicone that’s too thin. It might seal briefly, but under vibration or pressure, it can fail. For HVAC doors or joints, I recommend:

- 2mm: Light covers or small gaps

- 3mm: Duct flange seals, access panels

- 5mm: Heavy-duty enclosure doors or vibration isolation

Sheet size usually comes in 1m x 1m or 1m x 2m rolls. You can order bulk and trim as needed. For custom production, I sometimes ask suppliers to pre-cut to width, which saves time on job sites.

Here’s a quick reference:

| Use Case | Recommended Thickness |

|---|---|

| Light-duty duct seal | 2mm |

| Access panel gaskets | 3mm |

| Rooftop unit panels | 4–5mm |

| Anti-vibration pads | 6–8mm |

If in doubt, go one level thicker—especially for external applications.

Where Can I Get Reliable Cut-to-Fit Silicone Sheets?

After trying a few cheap suppliers, I realized the importance of consistent hardness and clean edges.

Choose a supplier that offers high-grade silicone, clear Shore hardness ratings, and customization options for HVAC needs.

I always look for:

- Shore A ratings (usually 50–70 for HVAC)

- UL94V-0 flame resistance, if needed

- UV and weather resistance

- Available in sheet and roll formats

- Custom-cutting or bulk ordering options

We provide durable silicone sheets that meet HVAC performance standards. We offer cut-to-size options, various thicknesses, and flame-retardant formulas upon request. I’ve used their products in both residential retrofits and commercial installations—and I’ve always been happy with the results.

Conclusion

Cut-to-fit silicone sheets provide flexible, reliable sealing solutions for HVAC systems of all shapes and sizes.