Silicone sheet prices can look similar on the surface, but the real cost lies in the details you don’t see.

Silicone sheet cost depends on factors like raw material grade, thickness, curing method, certifications, and customization options.

I used to compare silicone sheet quotes based only on price per kilogram. I learned quickly that it’s not just about cost—it’s about what you’re really getting for your money. Let me walk you through the key things that impact silicone sheet prices.

What Role Does Raw Material Quality Play?

You can’t make high-quality silicone sheets from low-quality ingredients.

Raw material grade significantly influences silicone sheet cost—platinum-cured and food-grade silicones are more expensive than general-purpose types.

There are two main curing systems: peroxide-cured and platinum-cured. Platinum-cured silicone is cleaner, safer, and used for medical and baby products. It costs more because it requires purer base materials and more precise processing.

Different silicone polymers also affect price. High-consistency rubber (HCR) and liquid silicone rubber (LSR) have different performance and processing needs. LSR is often used for precise, injection-molded parts, while HCR is better for sheet production.

When I source silicone sheets for baby products, I only work with suppliers who use medical or food-grade silicone. Yes, it’s pricier—but the safety and reliability are worth every cent.

How Does Thickness and Size Affect the Cost?

Buying thicker silicone sheets is not just paying for more material—it’s also about processing difficulty.

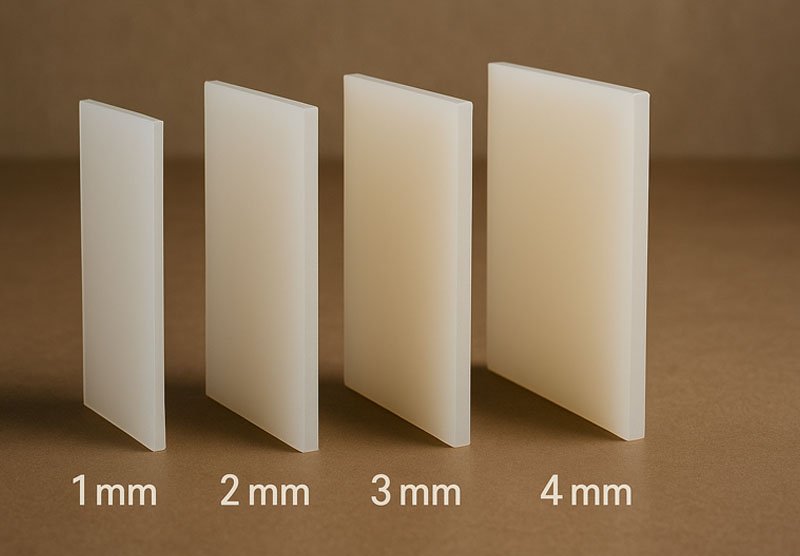

Thicker and larger silicone sheets cost more due to increased material use, slower curing times, and higher waste during production.

Most suppliers price silicone sheets by the square meter or square foot. Thickness plays a major role because it directly multiplies the raw material volume. A 5mm sheet can cost nearly double what a 2mm sheet costs, depending on the formulation.

Large custom-sized sheets can also require longer curing ovens, larger molds, and careful handling to avoid warping or air bubbles. Some sizes may need special tooling or secondary cutting processes.

Here’s a rough table comparing how size affects cost:

| Thickness (mm) | Cost Impact | Common Use Cases |

|---|---|---|

| 0.5–1.0 | Low | Electrical insulation, seals |

| 2.0–3.0 | Moderate | Kitchenware, baby products |

| 4.0–6.0 | High | Gaskets, cushioning sheets |

| 10+ | Very High | Industrial mats, padding |

For one client, we switched from a 4mm to a 2mm sheet and saved 30% without compromising function. Always test before you assume thicker means better.

Does Curing Method Influence the Price?

I once received a shockingly low quote—only to realize the sheets were peroxide-cured, not platinum.

Curing methods like peroxide or platinum have a direct impact on cost, quality, and application safety.

Peroxide-cured silicone is cheaper but leaves byproducts like benzene or formaldehyde. This is fine for industrial use but risky for food or baby contact. Platinum-cured silicone is cleaner, odorless, and more stable. That makes it ideal for FDA or LFGB-certified products, but it adds cost due to stricter controls.

Here’s a side-by-side comparison:

| Feature | Peroxide-Cured | Platinum-Cured |

|---|---|---|

| Cost | Lower | Higher |

| Odor | Slight, temporary | Odorless |

| Clarity | Cloudy | Transparent |

| Applications | General industry | Food, baby, medical |

| Safety Compliance | Limited | FDA, LFGB approved |

I never cut corners on curing when safety is involved. For baby teethers, the difference between the two is night and day.

Are Certifications and Compliance Important for Price?

I used to overlook certification costs—until I saw how much they matter in international markets.

Certifications like FDA, LFGB, and RoHS add to cost but ensure the silicone meets safety and environmental standards.

To certify a silicone sheet, the material and production must pass lab tests for toxicity, heavy metals, and migration. This involves expensive third-party testing, regular audits, and batch documentation.

For U.S. markets, FDA compliance is essential for food contact materials. For Europe, LFGB certification is even stricter. Some clients also demand RoHS or REACH certification for environmental compliance.

Here’s how certification impacts cost:

| Certification | Added Cost Impact | Benefit |

|---|---|---|

| FDA | Moderate | Access to U.S. market |

| LFGB | High | Safer and more regulated |

| RoHS/REACH | Low to moderate | Sustainability and export ease |

If your product touches food, skin, or babies, you need certified silicone—even if it adds to the price. I always include this when calculating the total cost of a project.

How Much Do Customization and Color Matching Cost?

Custom silicone might look simple—but it’s often more work than standard sheets.

Customized thickness, color, surface texture, or packaging all increase cost due to tooling, setup, and material batching.

Most manufacturers offer standard red or translucent silicone sheets. If you want Pantone color matching, textured surfaces, laser cutting, or printed branding, expect to pay more. These customizations require extra steps:

- Special pigment mixing

- Surface molding tools

- Additional QC inspection

- Low-volume runs or samples

Here’s what I consider “cost influencers” in customization:

| Customization Type | Cost Impact | Notes |

|---|---|---|

| Color matching | Moderate | Higher MOQ required |

| Surface texture | High | Needs tooling or embossing |

| Laser/logo cutting | Moderate to high | Depends on detail |

| Non-standard size | High | Longer lead times, more scrap |

I always ask clients if they really need the custom options. Sometimes we find a standard sheet that fits just as well and costs 20% less.

Does Order Quantity Affect Unit Cost?

Buying small quantities seems easier—until you compare price per sheet.

Larger orders reduce unit cost significantly due to economies of scale, optimized labor, and material efficiency.

Like most manufacturing, silicone sheet pricing benefits from bulk production. When I order 10,000 sheets, the cost per unit can drop by 25–40% compared to ordering 500. That’s because:

- Tooling and setup costs are spread out

- Raw materials are purchased in bulk

- Less waste per unit

- More efficient packaging and shipping

Here’s a rough pricing pattern I’ve seen:

| Quantity | Price per Sheet | Notes |

|---|---|---|

| 100–500 | High | Sample or pilot batch |

| 1,000–5,000 | Medium | Good for small production |

| 10,000+ | Low | Best unit price |

I always recommend clients forecast their needs for 6–12 months. Even if they don’t need everything now, batching orders saves serious money.

Conclusion

Silicone sheet costs depend on much more than just size or color—quality, curing, certifications, and volume all add up.