Ever scorched a table or workstation with a hot pan, soldering iron, or glue gun? It’s a costly mistake—damaging surfaces, halting workflow, or even causing safety risks. Cheap plastic or cloth mats just don’t cut it.

Heat resistant silicone mats are engineered to handle high temperatures without melting, warping, or releasing toxins. Whether you’re in a kitchen, lab, or electronics workspace, these mats offer a reliable heat barrier, are customizable to your needs, and protect your surfaces while improving safety and efficiency.

Let’s dive into what makes them so effective, and why your customers should never go without them.

Why Are Ordinary Mats Dangerous for High-Heat Environments?

Most standard mats can’t withstand temperatures beyond 100–150°C. Beyond that, they begin to deform, melt, or even emit harmful fumes. That’s dangerous in industrial, culinary, or crafting environments.

We’ve seen customers lose entire batches of products—or worse, experience injuries—because they relied on inferior materials. With heat resistant silicone mats, that worry is gone.

What Makes Silicone Heat Resistant?

Silicone has a unique molecular structure that gives it outstanding thermal stability. It remains stable across an extremely wide range of temperatures.

- Typical heat resistance: –40°C to +230°C

- High-temp silicone (special blends): up to +300°C or more

The cross-linked polymer structure of silicone allows it to stay flexible and non-toxic even under direct heat, making it ideal for hot tool stations, ovens, and countertops.

Applications: Where Heat Resistant Silicone Mats Are Essential

You’ll find these mats in a wide range of industries and household settings. Here’s where they truly shine:

- Kitchen & Baking: Perfect for placing hot trays, pans, pots, or handling chocolate/candy work.

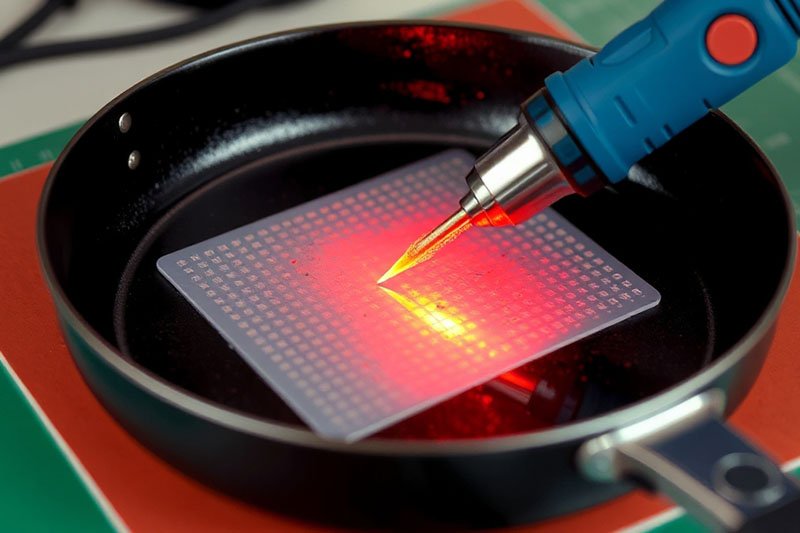

- Electronics Workstations: Protects workbenches from soldering heat or glue guns.

- Beauty Industry: Heat mats under curling irons or straighteners.

- Crafting & DIY: Ideal for resin work, candle-making, and other high-heat processes.

- Industrial & Lab Use: Acts as a thermal buffer in equipment maintenance or chemical testing environments.

These mats don’t just survive the heat—they work with it.

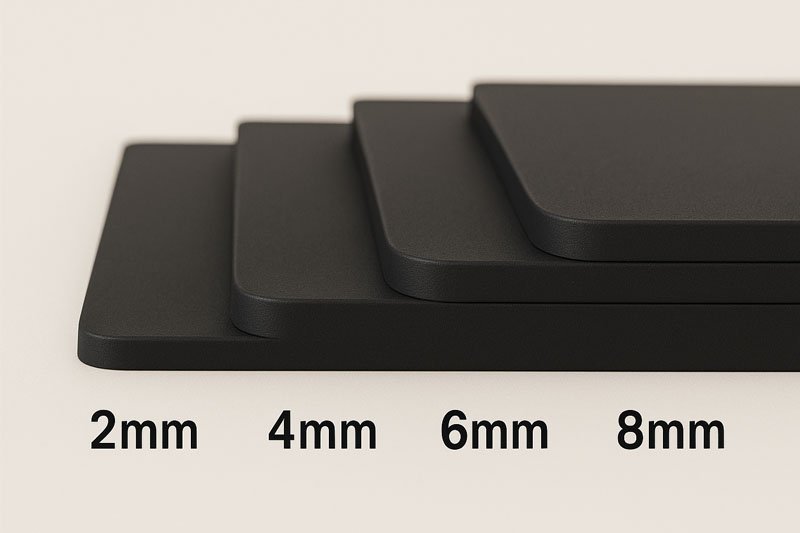

How Thick Should Heat Resistant Silicone Mats Be?

Thickness plays a major role in thermal insulation and durability. Here’s a general guide:

- 1–2 mm: Best for lightweight kitchen use or baking trays.

- 3–5 mm: Ideal for soldering stations, labs, or daily-use countertops.

- 6 mm and up: Heavy-duty environments like industrial floors or under large hot equipment.

We always recommend adjusting the thickness based on temperature exposure and application. Want to hold a 200°C oven tray for 5 seconds? Go thick.

Customization Options for Heat Resistant Silicone Mats

Just because it’s functional doesn’t mean it can’t look good or promote your brand.

At Ruiyang Silicone, we offer:

- Custom Dimensions: From small tool pads to large work surface covers.

- Color Matching: Brand-specific or color-coded for different stations.

- Logo Customization: Embossed, debossed, or printed branding adds a professional touch.

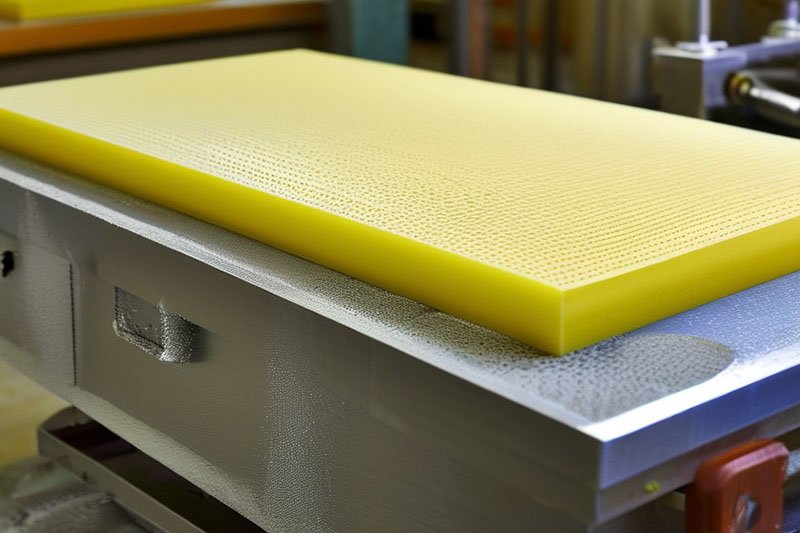

- Textured Surfaces: Grippy patterns like honeycomb or ridges reduce slipping and improve airflow beneath hot items.

Customization isn’t just about aesthetics—it improves functionality too.

What is the Manufacturing Process for Heat Resistant Mats?

Here’s how we produce top-tier heat resistant silicone mats at Ruiyang:

- Material Preparation: We select premium heat-resistant silicone compounds (food-grade, REACH-compliant, and FDA/LFGB certified).

- Molding Process: Using injection or compression molding machines, we shape the mats precisely based on the desired size and texture.

- Temperature Curing: The mats are heat-cured to enhance elasticity and heat resistance.

- Surface Finishing & Logo Application: We apply your branding using the selected method—debossed, printed, etc.

- Quality Inspection: Every mat undergoes a heat-resistance test to ensure it performs under pressure.

- Packing & Shipping: Mats are packed securely to retain shape and cleanliness during transit.

Safety Certifications and Quality Control

When it comes to high-heat applications, safety isn’t optional. Here’s what we guarantee at Ruiyang Silicone:

- LFGB and FDA Certified: Safe for direct food contact.

- REACH Compliant: Non-toxic and environmentally friendly.

- ISO 9001 Standards: Full quality management throughout the process.

We don’t play games with fake certificates. Everything is real, verified, and shared transparently with our B2B clients.

How Do Heat Resistant Mats Improve Operational Efficiency?

Here’s where the rubber (or silicone) meets the road.

- Protect Surfaces: Prevent permanent heat damage on valuable workstations or equipment.

- Reduce Downtime: No more halting work because of heat warping or burns.

- Improve Safety: Fewer accidents, especially in kitchen, electronics, or industrial environments.

- Boost Productivity: Workers spend less time worrying about tools damaging the workspace.

And let’s not forget—these mats are reusable, washable, and long-lasting, giving serious ROI.

FAQs About Heat Resistant Silicone Mats

Q: Can I use these mats directly in ovens?

A: Absolutely. Our food-grade mats withstand baking temperatures and are safe for direct contact with trays and food.

Q: Are the mats dishwasher safe?

A: Yes! Silicone is waterproof and easily cleaned with soap and water or in dishwashers.

Q: What’s the turnaround time for custom orders?

A: Typically 15–20 days depending on complexity and order volume.

Q: What’s the MOQ for custom heat mats?

A: Usually 100 pcs, but we can flex that based on your project’s needs.

Q: Can I request temperature testing data?

A: Of course. We provide lab results and temperature resistance data for your peace of mind.

Conclusion

Heat resistant silicone mats aren’t just an accessory—they’re a critical safety and efficiency upgrade for any high-temperature workspace. Whether you’re soldering, baking, or crafting, the right mat protects your equipment, your people, and your brand.

At Ruiyang Silicone, we specialize in custom silicone mats made to endure the heat—literally and figuratively. Let’s talk about your next project and design a solution that fits your brand like a (heatproof) glove.