Food-grade silicone is trusted for its safety, heat resistance, flexibility, and durability. It’s widely used in baby products, kitchenware, and medical devices. Choosing a supplier that truly uses food-grade materials is key to protecting product safety and consumer health.

This guide will walk you through practical ways to verify if a silicone supplier meets food-grade standards. From certification review and lab testing to factory audits and long-term risk control, each step helps ensure you’re working with the right partner.

What Is Food-Grade Silicone?

Food-grade silicone is a special type of silicone made to meet international food safety standards. It won’t release harmful chemicals when in contact with food. Known for its safety, flexibility, and heat resistance, this material is widely used in baby pacifiers, teething toys, baking molds, medical tubes, and sealing parts.

In the United States, food-grade silicone falls under FDA 21 CFR 177.2600. This regulation lists approved ingredients and sets strict limits on how much can leach out under certain conditions.

Europe also has strong standards. LFGB is a strict German regulation trusted across many countries, while EU 1935/2004 sets the baseline for food contact materials across the EU. Other rules like RoHS and REACH focus on limiting heavy metals and harmful substances.

For baby products, safety labels such as BPA-free and Phthalate-free are key indicators. A truly food-grade silicone should be stable and inert. It won’t react with food. There’s no smell, no taste. The material handles both high and low temperatures without breaking down. It also resists bacteria and remains safe in acidic or alkaline conditions.

How to Review a Silicone Supplier’s Certifications and Test Reports?

To confirm that silicone is truly food-grade, your supplier must provide clear and trustworthy documentation. Below is a practical guide to the key documents and how to evaluate their reliability.

Key Certifications and Declarations

- FDA Compliance Statement

This is the most basic and direct proof. The document should clearly refer to FDA 21 CFR 177.2600, and confirm that the material passed extractables testing under food-contact conditions.

- Raw Material Traceability

Ask the supplier to provide documentation from their upstream raw material provider. Well-known silicone brands such as Dow Corning, Shin-Etsu, and Wacker usually offer reliable, food-grade raw materials.

- Quality Management Certifications

Certifications like ISO 9001 or ISO 22000 don’t prove food safety directly, but they show the supplier has a structured production process and strong quality control.

Third-Party Lab Reports Are the Gold Standard

Independent reports from trusted labs like SGS, Intertek, TÜV Rheinland, or UL are essential to prove product safety. Here are the most important test items and what they mean.

| Test | Purpose |

| Extractables Test | Verifies compliance with FDA 21 CFR 177.2600. Measures how much material may migrate into food. |

| VOC Testing | Measures volatile organic compounds released under heat or room temperature. |

| Heavy Metal Testing | Checks for lead, cadmium, mercury, and other harmful metals. |

| BPA & Phthalates | Especially important for baby and children’s products. Ensures no toxic plasticizers. |

| Sensory Test | Checks for odor or taste transfer to food. |

What to Check in the Test Report

- Date: Is the report still valid? In general, reports older than one year should be updated.

- Sample Match: Does the product name, model, or color match the item you plan to order?

- Test Method: Is it based on FDA 21 CFR 177.2600, LFGB, or other food-contact standards?

- Lab Credentials: Is the lab accredited by CNAS, ILAC-MRA, or other globally recognized systems?

How to Evaluate a Silicone Supplier’s Production Process?

Reviewing documents is important, but to truly verify if a supplier meets food-grade standards, on-site inspection is essential. Seeing how they actually produce their products gives you a clearer picture of their hygiene control and process reliability.

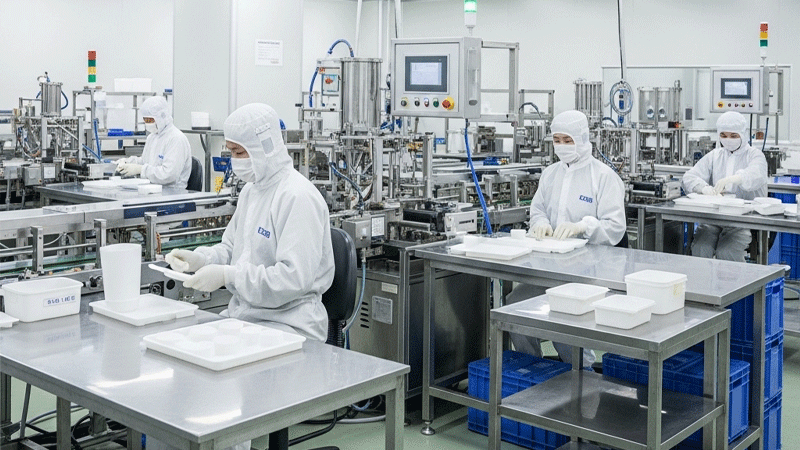

Is the Production Environment Clean and Controlled?

Food-grade silicone must be made in a clean, well-managed space to avoid contamination. Key things to check include:

- Dedicated production lines: Is there a separate line for food-grade silicone? It should not mix with non-food materials.

- Cleanroom conditions: Ideally, the factory should have dust-free rooms (like ISO 14644 Class 8), with air filters and insect control in place.

- Staff hygiene: Do workers wear proper gear—clean suits, gloves, masks, and hats? Are they following entry and disinfection protocols?

Is Raw Material Storage Safe and Traceable?

Food-grade safety starts from the raw materials. During the visit, check the following:

- Storage conditions: Are silicone materials stored separately? Are they kept in dry, ventilated, and light-protected areas?

- Batch traceability: Can the factory trace each batch of materials back to its source, production date, and operators involved?

This level of tracking is vital for quick recalls and quality accountability.

Are the Production Steps Well Controlled?

Stable, high-quality output depends on process discipline. Focus on these steps:

- Material mixing and feeding: Are there systems in place to avoid mix-ups? Does the supplier use automated feeding for better accuracy?

- Curing process: Is temperature and time strictly controlled? Undercured products may contain residual monomers or unwanted odors.

- Tool and machine cleaning: Are molds cleaned regularly? Are food-grade stainless steel or medical-grade materials used to prevent metal leaching?

How to Build a Sustainable Supplier Management System?

Verifying food-grade silicone is not a one-time task. It’s part of a long-term quality assurance process. A well-structured supplier management system helps ensure ongoing material compliance, product safety, and stable cooperation.

Sign a Clear Quality Agreement

When starting a partnership with a supplier, always sign a detailed Quality Agreement. This agreement should clearly define:

- Which standards the materials must follow (such as FDA 21 CFR 177.2600, LFGB, or GB 4806)

- Required testing items and frequency (e.g., migration tests, VOC tests, heavy metal tests)

- How to handle non-conforming products, including roles and responsibilities

- Advance notice for any material or formula changes

- Penalties and compensation terms for quality violations

A good agreement sets a shared understanding of expectations. It also provides legal protection and helps both sides follow the same quality goals.

Set Up Regular Audits and Sampling Plans

To avoid situations where the first batch meets standards but later ones fall short, create a schedule for routine checks. A mix of on-site visits and random testing helps maintain long-term control.

| Activity | Suggested Frequency | Purpose |

| On-site Audit | Once a year or every 2 years | Check production flow, cleanliness, and documentation |

| Third-Party Sampling | Every quarter or every 6 months | Test materials or products through certified labs |

| Document Review | Once a year | Review test reports, MSDS, and certification validity |

These steps help ensure the materials still meet food-grade requirements, not just on paper, but in actual production.

Conclusion

Verifying food-grade compliance isn’t just about checking a few documents. It takes a full-scope approach—clear certifications, reliable testing data, on-site inspections, and ongoing quality management. This is how you protect your brand, meet safety standards, and earn consumer trust.

If you’re looking for a reliable food-grade silicone supplier, we’re here to help. With over 10 years of industry experience, we offer full-service material testing and supply chain solutions tailored to your needs.