You’re standing at a crossroads in your product development. Your team needs silicone parts, but the supplier is throwing around terms like “LSR” and “HTV” with wildly different price quotes. One promises faster cycles but demands higher tooling investment. The other seems cheaper upfront but might bottleneck your production line.

LSR (Liquid Silicone Rubber) uses injection molding with automated cold runner systems, delivering faster cycles and superior consistency for high-volume production. HTV (High-Temperature Vulcanizing) silicone relies on compression molding, offering lower tooling costs but slower throughput. Your choice hinges on annual volume, part complexity, and quality requirements—LSR excels at micro parts and medical-grade applications, while HTV suits prototyping and mid-volume batches.

But here’s what most engineers miss: the “cheaper” option often becomes the expensive one when you factor in cycle time, scrap rates, and post-processing labor. I’ve seen procurement teams commit to HTV tooling only to scramble for LSR capacity six months later when demand doubled. Let’s break down exactly how these processes differ and when each makes financial sense.

What Makes LSR Injection Molding Different from HTV Compression?

I remember the first time I watched an LSR machine cycle. The precision was mesmerizing—liquid material flowing through heated channels, filling micro-cavities in seconds. Then I saw an HTV press, where an operator manually placed preforms into the mold. Night and day.

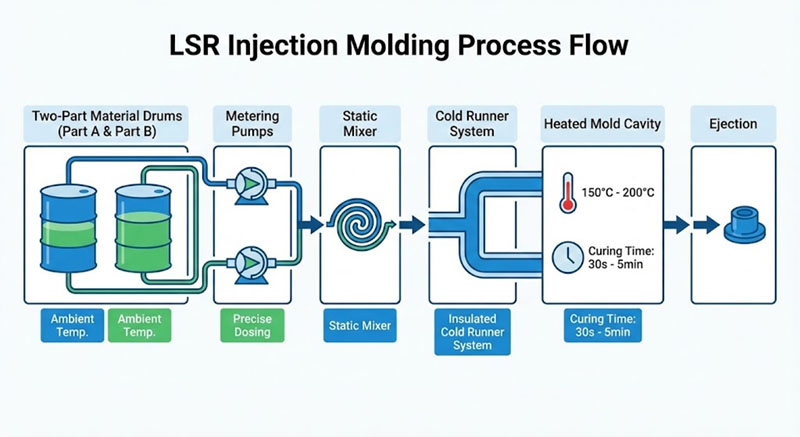

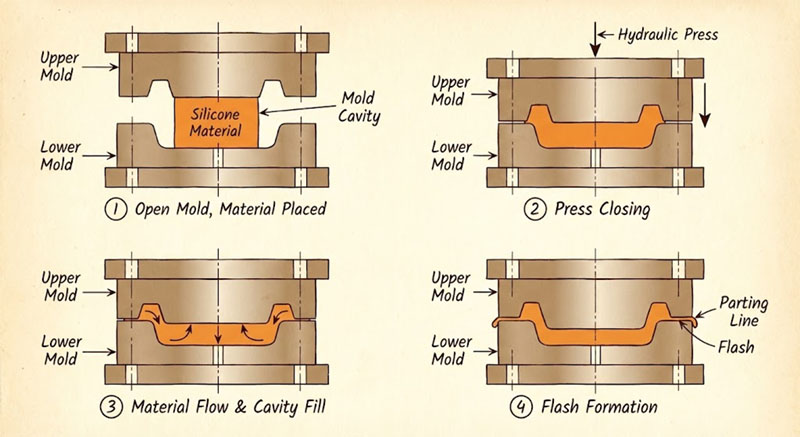

LSR injection molding pumps two-part liquid silicone through a cold runner system into heated molds (typically 170-200°C), curing in 20-60 seconds per cycle. HTV compression molding places pre-mixed silicone chunks into open molds, then presses and heats them (150-180°C) for 3-10 minutes. LSR automates material handling and reduces labor, while HTV requires manual loading and longer cure times.

Process Mechanics: Cold Runner vs Manual Loading

The LSR cold runner is the game-changer. It keeps the two-part silicone separate until the mixing nozzle, preventing premature curing. This system allows for:

- Fully automated cycles: No operator touching material between shots

- Consistent shot weights: Precision pumps deliver ±0.5% repeatability

- Zero flash waste: Cold runner material returns to the supply drums

HTV, by contrast, uses solid or putty-like silicone. Operators weigh chunks, place them in cavities, and trim excess flash after curing. I’ve timed this—even skilled workers need 15-30 seconds per cavity for loading. On a 4-cavity mold, that’s 2 minutes of manual labor per cycle before the press even closes.

Here’s the cost breakdown I use with clients:

| Factor | LSR Injection | HTV Compression |

|---|---|---|

| Cycle Time | 20-60 seconds | 3-10 minutes |

| Labor per Cycle | 0 seconds (automated) | 60-120 seconds |

| Material Waste | <2% (cold runner recycles) | 10-15% (flash trimming) |

| Tooling Cost | $15,000-$50,000 | $3,000-$12,000 |

The LSR tooling premium hurts upfront. But when you’re making 100,000 parts per year, those 4-minute cycle time savings compound. I calculated for one client that LSR paid back its tooling difference in 8 months purely through reduced labor and increased throughput.

How Do Quality Standards Compare Between LSR and HTV?

A medical device client once rejected an entire HTV batch because of visible voids in the silicone. The material hadn’t de-aired properly during mixing. We switched them to LSR and the problem vanished. Not because HTV is inherently defective—but because LSR’s process controls are tighter.

LSR delivers optical-grade transparency, minimal volatile residues (FDA-compliant out of the gate), and part-to-part consistency within ±0.02mm tolerances. HTV can achieve similar material properties but requires post-curing (4-8 hours at 200°C) to eliminate residual peroxide, and manual mixing introduces variability. For medical, food-contact, or infant products, LSR’s inherent purity and consistency justify the investment.

Material Purity and Post-Processing Requirements

LSR cures through platinum catalysis. No peroxides, no byproducts. Parts come out of the mold ready for assembly. HTV uses peroxide crosslinking, which leaves trace residues. I’ve measured volatile organic compound (VOC) levels in as-molded HTV parts at 800-1200 ppm. After post-curing, they drop to <100 ppm—but that’s an extra oven cycle, energy cost, and 8 hours of lead time.

The odor difference is immediate. Fresh HTV parts smell like rubber bands. LSR parts? Odorless. For consumer products—baby bottle nipples, kitchen utensils, wearable sensors—that sensory experience matters. I’ve had brands reject HTV samples purely on smell, even when the material met specifications.

Transparency is another tell. LSR can achieve water-clear optics for light pipes, lens seals, and aesthetic parts. HTV’s mixing process traps micro-bubbles, giving even “clear” grades a translucent, milky appearance. I use this comparison table with designers:

| Property | LSR (As-Molded) | HTV (Post-Cured) |

|---|---|---|

| Transparency | Optical-grade clear | Translucent to opaque |

| VOC Residues | <50 ppm | <100 ppm (after post-cure) |

| Odor | None | Faint rubber smell |

| Dimensional Tolerance | ±0.02 mm | ±0.05 mm |

For prototyping, HTV’s variability is forgivable. But once you’re shipping 50,000 units per month, that ±0.05mm tolerance means rejected assemblies and warranty claims. I watched a client’s seal failure rate drop from 2.3% to 0.1% by switching from HTV to LSR for their gasket. The LSR tooling cost $28,000 more, but they saved $15,000 per month in rework labor.

When Does HTV’s Lower Tooling Cost Make Sense?

Not every project needs LSR. I had a startup designing a custom grip for adaptive bicycle pedals. They needed 500 parts for a pilot program. LSR tooling would have cost $35,000—more than their entire prototype budget. We went with HTV compression molds at $6,000 and delivered parts in 3 weeks.

HTV compression molding is ideal for annual volumes under 50,000 parts, large or thick-walled geometries (over 10mm), and projects with uncertain demand. The lower tooling investment reduces financial risk, and the process handles material variations (like adding fillers or pigments) more forgivingly. For short production runs, prototypes, or parts where cycle time isn’t critical, HTV’s economics win.

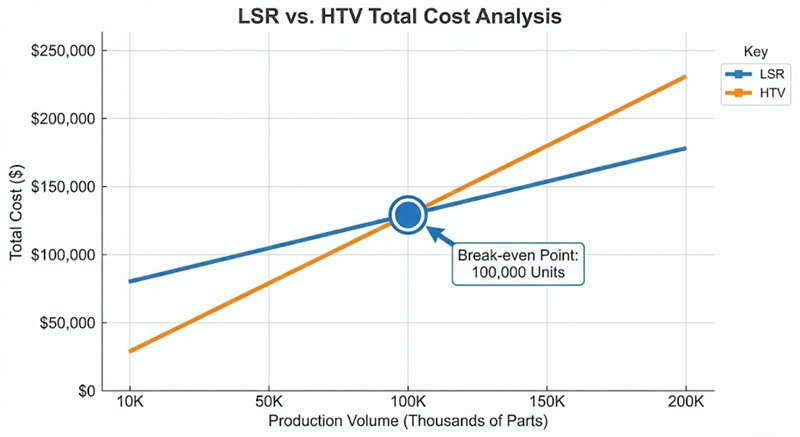

Volume Break-Even Analysis

I run this calculation for every client: at what production volume does LSR’s per-part cost advantage offset its tooling premium? The formula considers cycle time, labor rates, material waste, and machine hour costs. Here’s a real example from a consumer electronics project:

- LSR scenario: $40,000 tooling, 35-second cycle (4-cavity), $0.18 material per part, $0.05 machine/labor per part = $0.23 per part + amortized tooling

- HTV scenario: $8,000 tooling, 5-minute cycle (4-cavity), $0.15 material per part, $0.42 machine/labor per part = $0.57 per part + amortized tooling

At 10,000 parts: LSR total cost = $40,000 + ($0.23 × 10,000) = $42,300. HTV total cost = $8,000 + ($0.57 × 10,000) = $13,700. HTV wins.

At 100,000 parts: LSR total cost = $40,000 + ($0.23 × 100,000) = $63,000. HTV total cost = $8,000 + ($0.57 × 100,000) = $65,000. LSR wins.

The crossover happens around 90,000-120,000 parts, depending on part complexity. But there’s a hidden factor: lead time. If your product launch depends on shipping 20,000 units in 4 weeks, LSR’s 35-second cycle means one press can produce 500 parts per 8-hour shift. HTV at 5 minutes per cycle? Only 96 parts per shift. You’d need 5 HTV presses to match one LSR line.

I also consider design flexibility. LSR excels at thin walls (down to 0.3mm), undercuts, and micro-features. I’ve molded LSR keypads with 0.5mm button walls and integral living hinges—impossible in HTV compression. If your part geometry pushes the limits of moldability, LSR’s injection pressure and flow characteristics give designers freedoms that HTV simply can’t match.

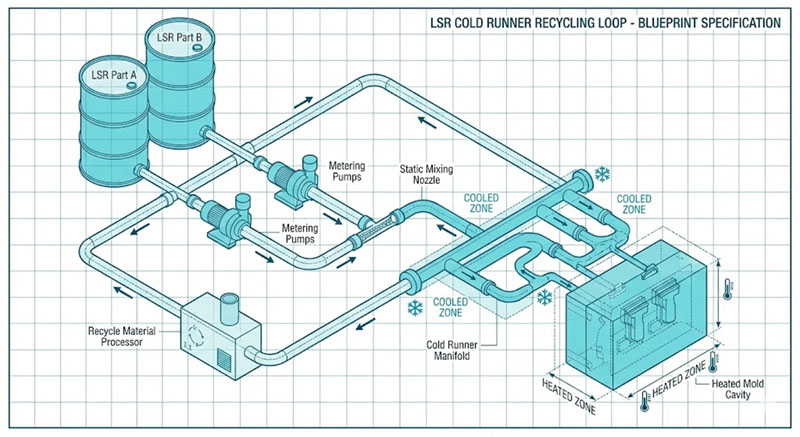

What About Cold Runner Material Recycling?

A client once asked me, “If the cold runner recycles material, why does LSR still have any waste?” Great question. The answer involves practical realities of production and material shelf life.

LSR cold runner systems recycle uncured material back to the supply drums, achieving near-zero waste during steady-state production. However, startups, shutdowns, and color changes generate 2-5% scrap. The two-part silicone has a pot life (time before it begins curing) of 4-8 hours in the cold runner, so overnight shutdowns require purging. HTV generates 10-15% waste from flash trimming that cannot be reprocessed without degrading properties.

Material Handling and Pot Life Realities

LSR’s two-part system is elegant but demanding. Part A (base) and Part B (catalyst) sit in temperature-controlled drums. Pumps meter them at precise ratios (typically 1:1 or 10:1) into a static mixer at the injection nozzle. Once mixed, the clock starts ticking. Most LSR grades cure fully in 10-30 minutes at room temperature—faster if exposed to heat.

During production, the cold runner keeps material at 15-25°C, slowing the cure. As long as the line runs continuously, material cycles through every 2-3 minutes and never fully cures in the runner. Waste is minimal—just the small amount in the mixing nozzle that can’t be recovered.

But stop the line for lunch? The material in the runner starts to gel. After 4 hours, it’s partially cured and unusable. We purge it—2-3 shots’ worth of material—before resuming. For a 20-gram part, that’s 60 grams of waste per restart. On a single-shift operation with one lunch break and one afternoon stoppage, that’s 120 grams per day. Over a year, it adds up.

HTV waste is more straightforward: it’s the flash you trim off. Compression molds intentionally overpack to ensure complete cavity fill, so excess material squeezes out the parting line. On a simple gasket, flash might be 10% of the part weight. On complex geometries with multiple parting lines, it can hit 20%. And you can’t just re-mix it—once HTV is crosslinked, it’s thermoset. Game over.

Some suppliers offer HTV regrind services, where they pulverize scrap and blend it with virgin material at 10-20% ratios for non-critical applications. But the properties degrade—tensile strength drops 15-25%, elongation suffers. I only recommend this for cost-driven projects where performance isn’t tightly specified.

Conclusion

Choose LSR when volume exceeds 50,000 parts annually, design complexity demands thin walls or tight tolerances, and quality standards require FDA-grade purity. Accept HTV’s simplicity for prototypes, low-volume production, and thick-walled parts where cycle time and labor costs don’t dominate your economics.