Silicone bakeware is loved by both home cooks and professional bakers. But have you noticed that not all silicone tools feel the same? Some look shiny and smooth, while others feel soft and matte. This difference comes down to surface finish—glossy vs. matte.

In this article, we’ll explore these two finishes from different angles, including how they’re made, how they perform, and how they feel in real use. With this guide, you’ll be better prepared to choose the right finish based on your product goals and user needs.

What Are Matte and Glossy Finishes?

In silicone products, surface finish refers to the texture created by the mold or added through post-processing. The two most common types are glossy and matte finishes.

A glossy finish feels smooth and has a subtle shine. It reflects light well, giving the product a clean, polished appearance. A matte finish, on the other hand, has a soft, frosted texture with little to no shine. It looks more understated and feels dry to the touch.

There’s no right or wrong choice, just different finishes for different needs. Surface texture not only affects how the product looks, but also how it feels and functions. It can influence mold release, grease resistance, and how easy the item is to clean.

How Are Glossy and Matte Silicone Surfaces Made?

The difference in surface finish comes from how the silicone is made. Glossy and matte surfaces use different mold treatments during production.

Matte Silicone

A matte surface comes from special treatments on the mold. Common methods include:

- Sandblasting: The mold is blasted with fine particles to create tiny, even textures.

- Etching or Engraving: Chemicals or lasers create a dull pattern on the mold surface.

Some makers also add matte agents to the silicone or spray a matte coating after molding. But for food-grade items, all materials must be safe and approved.

Cost Note: Matte molds are more complex to make. They often cost more at the start. They also need better cleaning and care to keep the texture even.

Glossy Silicone

Glossy surfaces come from molds that are polished until smooth like a mirror. This smooth surface gives the silicone a bright, shiny look after molding.

Cost Note: Glossy molds cost more to make. They need better steel and high-level polishing. During production, the area must stay clean. Any dust can affect the final shine.

How Do Matte and Glossy Finishes Feel and Look Different?

When choosing silicone products, people often wonder whether surface finish affects how a product looks or feels. The truth is, both matte and glossy finishes have their own strengths. The right choice depends on how the product will be used and the kind of experience you want.

The table below compares these two finishes in terms of look and feel to help you decide which suits your needs best.

| Feature | Matte Finish | Glossy Finish |

| Style & Look | Soft, understated, professional | Bright, vivid, highly eye-catching |

| Color Appearance | Milder tones, more neutral in feel | Rich and vibrant with strong color |

| Surface Touch | Dry feel, more grip, steady to hold | Smooth and sleek, low friction |

| Handling Comfort | Better grip, great for tool-like use | Looks good but more slippery—ideal for easy release |

Which Surface Performs Better in Real Use?

Surface texture may seem like a small detail. But it can affect how the product works, how easy it is to clean, and how long it lasts. Here’s a side-by-side comparison to help you understand the practical differences between glossy and matte finishes.

| Performance | Glossy Surface | Matte Surface |

| Non-stick Ability | Easy to release cakes and chocolate molds | Slightly less effective, especially with sugary foods |

| Ease of Cleaning | Rinses off easily but may show water marks or fingerprints | Needs more care to remove grease |

| Scratch Resistance | Scratches easily and shows wear over time | More durable and hides daily wear |

| Oil Resistance | Smooth surface resists oil stains | Porous texture may trap grease |

| Product Longevity | Needs proper care to avoid surface aging | Longer lifespan and easier maintenance |

Which Finish Fits Your Product?

Glossy and matte finishes serve very different purposes. Choosing the right one can make a big difference in how a silicone product performs. Here’s how each finish fits different types of tools.

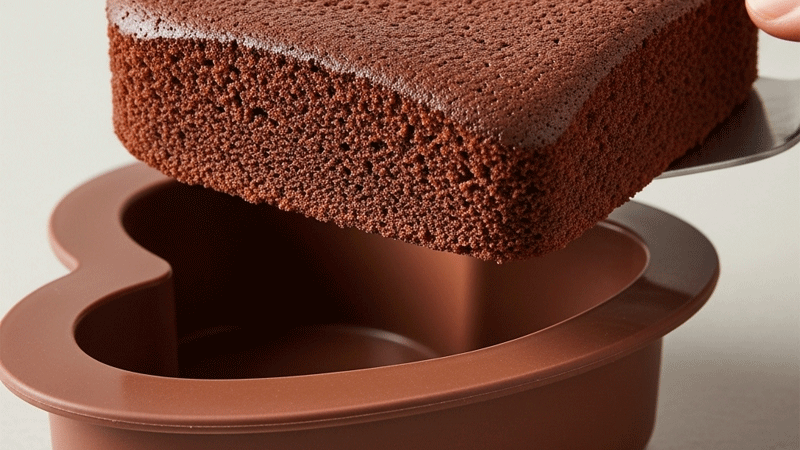

Glossy Silicone: Best for Clean Release and Visual Appeal

For cake or chocolate molds, a glossy surface is the top choice. Its ultra-smooth texture makes it much easier to release baked goods without tearing or sticking. This helps keep the original shape and fine details intact.

Glossy silicone is especially ideal for chocolate molds. It gives the finished chocolate a shiny, polished look, making it more attractive and marketable.

Matte Silicone: Better Grip and Safer Handling

For tools that involve more hands-on operation, matte surfaces offer clear advantages. Items like baking mats benefit from better grip on the countertop. Whether you’re kneading dough or rolling it out, a matte-finished mat stays in place, making the whole process smoother and safer.

The same goes for handheld tools like silicone spatulas. A matte surface provides a stronger grip, even when hands are wet or dusted with flour. Any product with a handle, such as brushes or whisk grip, can gain better control and comfort with a matte finish. The added friction improves handling and gives users a more secure feel during use.

Conclusion

Choosing matte or glossy isn’t just about looks. It’s a decision that affects user comfort, product function, manufacturing cost, and even brand identity. If you’re designing molds, glossy surfaces are often the better fit. But if your product needs grip, matte is a more practical choice.

Ready to create bakeware that looks great and performs even better? Get in touch—we’re here to help.