How is AI changing the way silicone products are made?

This article focuses on the role of AI in silicone molding. We will dive into Silicone AI-driven predictive molding and explore the benefits across different industries.

What Is Silicone AI-Driven Predictive Molding?

Silicone AI-Driven Predictive Molding is an emerging trend in the silicone industry. It combines artificial intelligence (AI) with advanced manufacturing techniques, particularly in silicone injection molding and compression molding. The main goal of this technology is to optimize the production process of silicone products through AI analysis. This leads to improved production efficiency, reduced defect rates and enhanced product quality.

How Does Silicone AI-Driven Predictive Molding Work?

The core of Silicone AI-Driven Predictive Molding is real-time data collection, analysis, and prediction. It dynamically adjusts key parameters in the molding process.

Data Collection and Sensors

Sensors such as pressure, temperature, vibration, and cycle time are embedded in molding equipment to collect real-time production data. For example, Liquid Silicone Rubber (LSR) injection molding machines are equipped with high-precision sensors to monitor mold cavity pressure and material flow rate.

Machine Learning Models

AI uses supervised learning and unsupervised learning algorithms to analyze historical and real-time data. These models establish relationships between process parameters and product quality. For instance, AI can predict mold wear or material defects by analyzing data from the last 1,000 molding cycles.

Predictive Maintenance

AI detects anomalies to predict potential equipment failures. For example, unusual vibration data may signal issues with the hydraulic system. AI can schedule maintenance in advance, reducing downtime.

Process Optimization

AI dynamically adjusts parameters like injection pressure, mold temperature, and curing time. This helps reduce defects and improves product consistency. For instance, AI can adjust the mold temperature from 180°C to 175°C based on real-time data to optimize silicone curing.

Quality Control

AI-driven vision systems use high-resolution cameras to detect surface defects. It can identify tiny flaws that are difficult to see with the naked eye, such as cracks as small as 0.01mm.

What Challenges Are Faced in Silicone AI-Driven Predictive Molding?

Despite its great potential, Silicone AI-Driven Predictive Molding faces several challenges in real-world applications.

- Data Quality and Quantity: The performance of AI algorithms heavily depends on high-quality and sufficient training data. In the silicone industry, the wide variety of products and complex process conditions make it difficult to collect comprehensive data.

- Model Complexity and Accuracy: Developing models that can accurately predict the complex silicone molding process is a challenge. It requires deep industry knowledge and advanced modeling techniques.

- Sensor Integration and Cost: Integrating various sensors into existing equipment can be costly. It also involves technical difficulties. Ensuring data reliability and real-time performance adds to the challenge.

- Algorithm Development and Deployment: Creating AI algorithms tailored to specific silicone molding processes and successfully deploying them in production environments requires multidisciplinary expertise.

- Integration of Industry Knowledge: To fully realize the potential of predictive molding, AI technology must be deeply integrated with the industry’s expertise and know-how.

How Can Trust in AI Models Be Established?

Although AI models excel in predictions, their decision-making process often remains a black box. Engineers and managers must build trust in these models before they can adopt and implement the recommendations.

To build trust, several actions are necessary.

First, model performance validation is crucial. This involves using independent datasets to rigorously assess the model and ensure reliable predictions in real-world production environments.

Next, consistency and stability are important. The model should demonstrate consistent behavior across different data subsets and time periods.

It is also essential to analyze failure cases. Tracking and examining incorrect predictions helps identify the causes of failure and improve the model.

User feedback is another key component. Establishing effective feedback channels encourages users to report issues and offer suggestions for improvement.

Regular monitoring and maintenance of the model are also vital. By regularly checking performance, potential issues can be addressed, and the model can be updated based on new data and process changes.

Finally, training and education for engineers and operators are necessary. Helping them understand the basics of AI models and how to use them can alleviate fear of the black box effect.

How Is AI Revolutionizing Silicone Manufacturing Across Different Industries?

This table highlights how AI technology is transforming silicone manufacturing across various industries. By integrating real-time quality control, predictive maintenance, and AI-powered customization, companies can enhance product performance, reduce defects, and optimize production efficiency. The examples provided demonstrate the significant benefits that AI-driven solutions bring to sectors such as medical, automotive, consumer goods, and electronics.

| Industry | Applications | AI Technology | Specific Examples | Key Benefits |

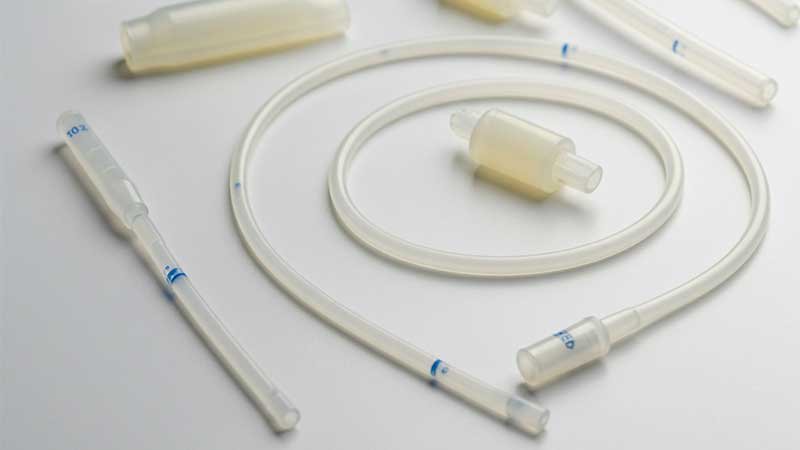

| Medical | Catheters, Seals, Implants | Real-time AI quality control | AI vision inspects 300+ silicone catheters/min (detects 15μm defects) | 99.99% medical compliance 62% defect rate reduction vs human inspection |

| Automotive | Seals, Gaskets, Vibration Dampers | Predictive maintenance & mold optimization | GM’s AI-optimized EV battery seals (23% weight reduction) | 40% fewer production halts 18% material savings |

| Consumer Goods | Baby Products, Kitchenware, Wearables | AI-powered customization | LilyPadz nursing pads (3D body scan → personalized silicone thickness gradients) | 5X design iteration speed 70% less material waste |

| Electronics | Encapsulation, Connectors, Flexible PCBs | Bubble/void prediction systems | iPhone 15 Pro Max waterproof seals (0.001mm³ bubble detection via X-ray + CNN) | 88% reliability improvement 50℃ wider thermal tolerance |

How Can Silicone AI-Driven Predictive Molding Contribute to Sustainability and Green Manufacturing?

AI-driven predictive molding can play a significant role in promoting sustainability and green manufacturing within the silicone industry.

By enhancing precision in production, AI helps reduce defects and waste, leading to better material utilization. Moreover, AI analyzes energy consumption data to identify the most energy-efficient production strategies. This helps in optimizing machine performance and reducing overall energy use. As a result, manufacturers can significantly lower their carbon footprint while maintaining high product quality.

What Are the Economic Benefits of Silicone AI-Driven Predictive Molding?

Implementing AI-driven predictive molding can bring significant economic benefits and a strong return on investment to the silicone industry.

The most direct benefit is the reduction in raw material costs. With AI’s accurate predictions and process optimization, production defects and waste are significantly reduced. This leads to less raw material being wasted and lowers procurement costs.

Moreover, AI-driven predictive molding can greatly improve production efficiency and shorten time to market. Optimized process parameters and a more stable production process result in higher output and shorter production cycles. This allows companies to respond faster to market demand and seize market opportunities. Additionally, predictive maintenance minimizes equipment downtime, ensuring continuous and stable production. This helps avoid financial losses caused by equipment failures.

From an investment perspective, while there may be initial costs in introducing AI systems, the long-term benefits outweigh the investment. These benefits come from material savings, lower manufacturing costs, and increased production efficiency.

Conclusion

AI-driven predictive molding is transforming the silicone industry, offering new levels of efficiency, quality, and sustainability. It is paving the way for smarter and more sustainable manufacturing and will help businesses stay competitive and meet market demands faster and more efficiently.

Let’s create the perfect silicone product for you. With our extensive experience and state-of-the-art manufacturing capabilities, we’re ready to deliver custom silicone solutions that are both innovative and reliable.