A great keypad feels effortless to press yet lasts for millions of cycles. Achieving that balance takes more than just good silicone — it requires precise engineering.

Silicone keypad performance depends on the careful integration of tactile design, travel distance, load force, and conductive solutions like carbon or gold pills.

When I first worked on an automotive control keypad, I realized how much a single gram of load change could affect the user’s experience. From soft-touch consumer buttons to rugged industrial panels, the same design principles apply.

Tactile Feel and Rebound Curve Design?

The tactile feel defines how users perceive quality. A soft, crisp click builds confidence; a dull or inconsistent press ruins it.

The rebound curve — the force-displacement relationship — determines tactile feedback, response speed, and comfort.

The force-displacement curve has three main regions:

- Pre-travel: Initial compression before actuation.

- Snap ratio region: The sharp drop that provides the “click.”

- Return curve: The release and rebound to rest position.

Typical Design Parameters

| Parameter | Recommended Range | Effect |

|---|---|---|

| Snap ratio | 40–60% | Defines tactile sharpness |

| Pre-travel | 0.2–0.5 mm | Controls initial resistance |

| Return time | < 50 ms | Ensures responsive rebound |

In one consumer electronics project, we found that increasing the snap ratio from 45% to 55% made the buttons feel more “premium” without sacrificing durability. However, too high a snap ratio can cause fatigue or double clicks.

Travel Distance, Load Force, and Lifespan?

Durability depends on balancing actuation force and deformation. Excessive compression shortens life, while too little pressure feels unresponsive.

Optimizing travel distance and load force ensures consistent tactile response throughout the keypad’s life.

In silicone keypads, travel distance and actuation load define both the tactile experience and lifespan. Short travel may speed up response, but it can lead to a “mushy” feel and lower rebound. Long travel enhances feedback but increases wear on domes.

Design Relationship Table

| Parameter | Typical Value | Design Impact |

|---|---|---|

| Travel distance | 0.6–1.2 mm | Longer travel = stronger feedback |

| Actuation load | 100–300 gf | Higher load = firmer press |

| Expected lifespan | ≥ 1,000,000 cycles | Defined by material and geometry |

Material hardness (usually 50–60 Shore A) also affects performance. Softer silicone gives a smoother feel but reduces tactile clarity over time. Consistent cycle testing — usually at 1.5× the expected actuation load — helps verify stability.

Conductive Solutions: Carbon Pills, Gold Pills, Conductive Coatings?

Electrical contact is the heart of a silicone keypad. Conductive elements must ensure low resistance, durability, and long-term stability under repeated stress.

Carbon pills, gold pills, and conductive coatings offer different balances of conductivity, durability, and cost.

When I designed a keypad for an outdoor control unit, we had failures after thermal cycling. The carbon pills cracked under repeated expansion and contraction. Switching to gold-plated pills solved the issue completely.

Comparison of Conductive Solutions

| Conductive Type | Contact Resistance | Durability | Cost | Typical Use |

|---|---|---|---|---|

| Carbon pill | 100–300 Ω | Moderate | Low | Consumer devices |

| Gold pill | < 50 Ω | Excellent | High | Automotive, medical |

| Conductive coating | 50–150 Ω | Limited | Medium | Low-profile keypads |

Carbon pills are standard for cost-sensitive designs, while gold pills excel in precision and reliability. Conductive coatings can reduce part count but require careful process control to prevent peeling or oxidation.

During development, always validate contact resistance after aging tests — temperature cycling, humidity, and repeated pressing — to ensure signal stability.

Waterproof and Breathable Design?

Keypads used outdoors or in wet environments must resist water without losing tactile sensitivity.

A well-designed waterproof silicone keypad balances sealing performance with air venting to preserve tactile feel.

In one marine device project, we used a perimeter sealing ring and a waterproof vent membrane. This allowed internal air to equalize pressure during pressing without trapping moisture.

Design Tips for Waterproof Keypads

| Design Feature | Purpose | Notes |

|---|---|---|

| Perimeter lip seal | Prevents liquid ingress | Match to housing groove |

| Vent membrane | Balances pressure | Use waterproof breathable film |

| Coated surface | Improves stain resistance | Verify LFGB/FDA compliance |

| Overmolded interface | Strengthens sealing | Use two-shot molding if possible |

How to Balance the Trade-off Between Waterproofing and Tactile Feel?

Sealing layers increase stiffness, which can reduce tactile clarity. To balance, reduce wall thickness around the button area or use a vent membrane to relieve internal air pressure during actuation.

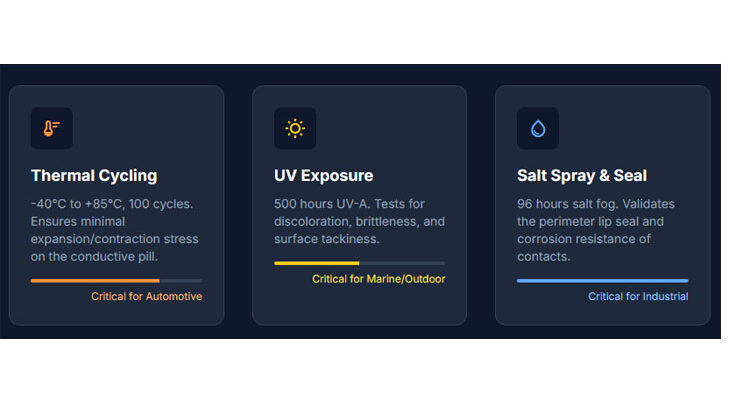

Environmental and Weather Resistance Validation?

Environmental exposure gradually alters silicone elasticity and conductivity. Testing ensures performance stability across real-world conditions.

Accelerated aging tests verify how tactile feel and electrical response hold up under temperature, UV, and chemical exposure.

For outdoor devices, we typically run 96-hour salt spray tests, 500-hour UV exposure, and -40°C to +85°C thermal cycling. For automotive interiors, humidity and temperature shock testing are key.

Typical Environmental Validation Plan

| Test | Condition | Evaluation Criteria |

|---|---|---|

| Thermal cycling | -40°C to +85°C, 100 cycles | No crack or resistance drift |

| UV exposure | 500 hrs (UV-A 340 nm) | No discoloration or tackiness |

| Chemical resistance | Wipe test (IPA, detergent) | No swelling or peeling |

| Lifespan test | 1M actuations | Consistent force ±10% |

By comparing pre- and post-test tactile curves, we can confirm design robustness. A well-formulated silicone compound retains elasticity even after long-term stress.

Conclusion

Silicone keypad design is an art of balance — between feel and function, between waterproofing and responsiveness, and between cost and reliability. A well-engineered keypad delivers a precise, consistent touch that endures millions of presses.

Want a custom keypad design optimized for your device?

Upload your keypad dimensions and target tactile feel, and our team will generate parameter recommendations and material options at RuiYang Silicone.