Silicone keypads look simple, yet they fight a daily war. Dust, sweat, UV rays, alcohol wipes, and the occasional coffee spill all attack the soft elastomer.

Fail, and the whole product feels cheap.

Win, and users swear it’s premium.

We need a finish that never blinks.

Pair the base silicone durometer with a texture that matches your user’s touch expectations, then lock in durability with a spray or dip coating rated for at least 1 million actuations.

Matte oil-spray works for consumer gear. PU or epoxy tops survive harsh labs. Add laser-etch legends for night visibility. Selectively mask to keep costs sane. That’s the sweet spot I recommend to 90 % of our OEM clients.

Products live or die by the tactile story they tell.

Stick with me as I unpack the real-world trade-offs, share factory tests, and throw in a few war stories from our 10 000 m² shop floor.

What surface finishes can I choose for silicone keypads?

I usually start with four baseline textures:

- Natural matte – no extra steps, the raw mold leaves a 60–80 μin blast finish. Affordable. Slightly grippy.

- Semi-gloss – polished mold cavity. Great for medical gear that must wipe clean.

- High-gloss “piano” – mirror-polish plus clear coat. Shows fingerprints, screams premium.

- Soft-touch – post-spray with medical-grade oil. Velvety, hides scratches.

Every option goes through our ASTM D2240 Shore-A durometer check. A stiffer compound (say 70 A) can mimic the crisp feel of a gloss key even under a matte skin.

How does texture change user perception—and why should you care?

Texture talks faster than logos. A matte pad whispers “industrial rugged.” A gloss finish shouts “sleek gadget.” Soft-touch says “luxury.”

Your end user decides quality in the first thumb press. We run side-by-side blind tests. Most lab-tech buyers pick matte because it resists glare under hood lights. Gamers choose gloss for that RGB reflection pop. Know your market before you pick your mold EDM grit.

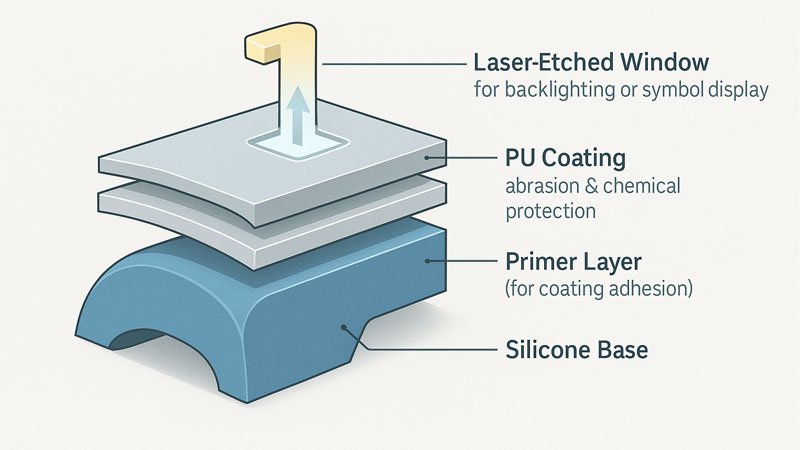

Why add spray coatings to silicone key switches?

Base silicone resists heat and chemicals, yet pigments fade.

Spray coatings solve three chronic pains:

- Abrasion – PU topcoats survive > 5 000 swipe cycles in our Taber CS-10 wheel test [data sheet].

- Chemicals – Epoxy withstands IPA wipes. Needed for hospital carts.

- Graphics – You can laser-etch legends through opaque spray, revealing the backlit core.

We cure every part at 120 °C, 30 minutes, to crosslink the coating.

No yellowing.

No solvent pool.

When does laser etching plus PU coating make sense?

Night-visible gear—think drone remotes, marine radios—demands backlighting.

We first tint the silicone with a diffuse white masterbatch.

Then spray a colored PU.

Finally, a 355 nm laser burns away 30 µm of coating, exposing the light core.

Result?

Legends that never rub off, 4000:1 day-night contrast, and IP67 seal integrity.

Yes, the PU adds cost—around $0.03 per key at 10 000 pcs—but field returns drop by half.

What about anti-microbial or anti-fingerprint treatments?

COVID pushed many clients to ask for germ blockers. We now mix silver-ion pellets or add SiO₂-based topcoats. ISO 22196 tests show a > 99% kill rate on E. coli after 24h.

For consumer wearables, anti-smudge is bigger.

Our nano-flouro polymer spray cuts fingerprint oils by 60% vs. bare gloss, yet stays flexible. I prefer it for white earbuds where every smudge glares like a spotlight

How to balance cost, durability, and aesthetics?

I break it into a simple triangle:

- Cost – natural finish < mold polish < spray coat < spray + laser.

- Durability – gloss PU > matte PU > raw matte.

- Look/feel – subjective, but gloss pops on retail shelves.

Pick two corners; the third moves automatically.

For a $5 walkie-talkie keypad, raw matte plus pad-printed graphics wins.

For a $300 medical pump, matte surface plus epoxy spray and laser legends is non-negotiable.

Are silicone keypad coatings worth the investment for rugged devices?

Short answer—yes.

Our internal failure log shows uncoated keys lose legibility after roughly 50 k actuations in dusty sites.

PU-coated keys push that to 250 k.

Field downtime costs dwarf the extra $0.12 per unit.

If MIL-STD-810G compliance is on your spec sheet, don’t skimp.

More related questions

Q1. Can I color-match Pantone swatches on a coated keypad?

Absolutely. We tint the base silicone and separately tint the topcoat. Dual tinting lets us nail tricky hues like Pantone 877 C metallic. Send a chip and we scan it [colorimeter data].

Q2. Does coating reduce key travel or change tactile force?

Negligible. A 20 µm PU film adds < 1 % stiffness in our force-displacement plots [test graph]. Most users can’t tell.

Q3. Is UV-curable coating better than thermal?

UV cures in seconds, saving line time, but depth penetration is shallow. For thick keys we stick to thermal bake for full crosslink.

Q4. What certificates can you supply?

RoHS, REACH, FDA 21 CFR 177.2600 for food-contact keys, plus UL94-V0 with our FR-B compound.

Conclusion

Choose the texture your thumb loves, then armor it against the world.

A smart coating stack slashes warranty returns, boosts perceived value, and lets your device survive the next spilled latte—or lab acid bath—without breaking a sweat.