Silicone is everywhere in modern kitchens. But how long can it truly last when exposed to heat, grease, and daily cleaning?

Evaluating silicone’s service life under air fryer, oven, and microwave conditions ensures both product safety and long-term durability.

When I worked with a client on an air fryer accessory line, they assumed all “food-grade” silicones were equally durable. After several heat cycles, some parts yellowed and hardened. That experience taught me that safety and longevity depend on how silicone is designed, processed, and tested.

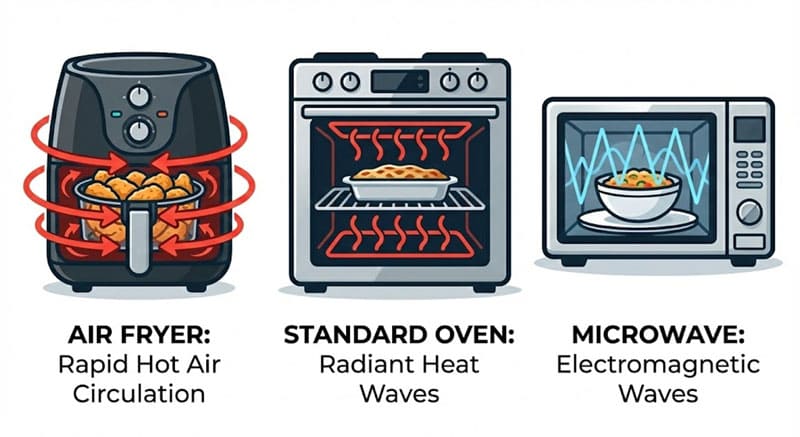

Operating Condition Definition: Air Fryers, Ovens, Microwaves?

Each kitchen appliance exposes silicone to unique temperature profiles, heating methods, and mechanical stresses. Understanding these conditions is the first step in service life evaluation.

Air fryers, ovens, and microwaves apply different heating mechanisms that influence silicone’s thermal stability and mechanical behavior.

We once tested an ultra-thin silicone mat that performed perfectly in standard ovens. However, in an air fryer, the powerful convection fan caused the lightweight mat to flutter and touch the heating element, resulting in immediate scorching. This highlighted that mechanical stability is just as critical as thermal resistance in air fryer applications.

Typical Operating Conditions

| Appliance | Temperature Range | Heating Type | Exposure Characteristics |

|---|---|---|---|

| Air fryer | 160–200°C [1] | Hot air convection | Repeated thermal cycling and oil contact |

| Oven | 180–230°C [1] | Radiant and convective | Prolonged high-temperature exposure |

| Microwave | 100–130°C [1] | Dielectric heating | Uneven heating, vapor pressure buildup |

Thermal Aging and Mechanical Fatigue?

Silicone retains elasticity at high temperatures, but long-term exposure leads to gradual hardening and cracking. Fatigue testing simulates years of real use.

Thermal aging and mechanical fatigue reduce silicone’s elasticity and tensile strength, directly shortening its usable life.

A pressure cooker seal used for two years showed no visible cracks, yet it began to leak. Testing revealed its hardness had shifted from 50 to 65 Shore A due to thermal aging, causing it to lose the elasticity needed to maintain a seal under high pressure—a failure mode invisible to the naked eye.

We exposed a 60 Shore A silicone baking tray to 200°C for 500 hours. The hardness increased to 68 Shore A, elongation dropped by 25%, and color changed slightly.[2][3] These changes correlated with oxidation of the polymer backbone.

Typical Aging Curve

| Condition | Exposure Time (h) | Hardness Change | Elongation Retention |

|---|---|---|---|

| 180°C air | 200 | +4 Shore A | 90% |

| 200°C air | 500 | +8 Shore A | 75% |

| 230°C air | 300 | +12 Shore A | 65% |

Mechanical fatigue tests, like repeated folding or compression, reveal how silicone degrades under repeated stress. After 100,000 compression cycles, high-consistency silicone usually maintains over 90% of its rebound elasticity.

Food Contact Safety and Odor Control?

Even after heat aging, silicone must remain safe for food contact. Poor compounding or contamination can cause odor, migration, or surface residue.

Ensuring food safety involves verifying compliance with FDA and LFGB standards while controlling volatile residues and odor generation.

Consumers complained that a batch of silicone ice trays made ice cubes tasting like “freezer burn” or garlic. The culprit was insufficient post-curing, which left volatile residues in the silicone. These residues not only produced odors but also made the silicone porous enough to absorb strong smells from other foods in the freezer.

When developing baking mats, I once received customer feedback about “rubber smell” after use. Testing showed residual volatiles from incomplete curing. After extending the post-curing step from 4 to 8 hours at 200°C, the odor disappeared.

Food Contact and Odor Control Measures

| Control Step | Purpose | Typical Requirement |

|---|---|---|

| Post-curing | Removes volatile residues | ≥ 4 hrs @ 200°C[4] |

| Migration testing | Ensures safety under heat | < 10 mg/dm² (EU 10/2011)[5] |

| Odor testing | Sensory evaluation after heating | No perceptible odor after 2 cycles |

Silicone should be validated under realistic heating conditions. For instance, even if migration results pass at 100°C, additional tests at 200°C should be conducted for air fryer or oven applications.

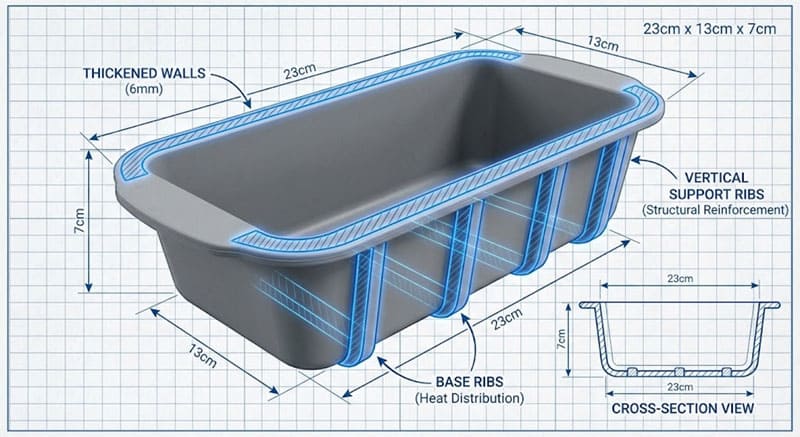

Structure and Thickness Design?

The design of silicone parts influences not only performance but also their thermal and mechanical stability.

Wall thickness, geometry, and support structures determine how evenly silicone heats and how it resists deformation under load.

A large rectangular loaf pan we designed initially failed during testing; as the batter heated, the sidewalls bulged outward, ruining the bread’s shape. The material was heat-resistant, but the structural design lacked sufficient rigidity. Adding vertical ribs and increasing wall thickness from 2mm to 3mm resolved the deformation.

During a bakeware project, we noticed that 5 mm-thick trays developed micro-bubbles after repeated oven use. Reducing the thickness to 3 mm and adding internal ribs distributed stress better and prevented deformation.

Design Guidelines for High-Temperature Silicone

| Feature | Recommended Range | Benefit |

|---|---|---|

| Wall thickness | 2–3 mm for small items | Faster heat transfer, less stress |

| Support ribs | Every 40–60 mm | Prevent sagging at high temp |

| Reinforcement rings | Stainless or glass-filled inserts | Dimensional stability |

| Vent holes | Near thick areas | Prevent bubble formation |

Proper airflow around the silicone surface also helps reduce localized overheating and discoloration in ovens and air fryers.

Impact of Cleaning and Maintenance?

Cleaning agents and methods affect the long-term durability and appearance of silicone kitchenware.

Harsh detergents or abrasive tools accelerate surface wear and oxidation, shortening service life.

A commercial bakery reported their non-stick mats were becoming sticky and degrading rapidly. We found they were using a heavy-duty, high-alkaline degreaser. The high pH attacked the silicone backbone, breaking down the surface. Switching to a pH-neutral cleaner stopped the degradation immediately.

Cleaning Recommendations

| Cleaning Factor | Impact | Best Practice |

|---|---|---|

| Dishwasher detergent | May cause whitening | Use neutral pH detergents |

| Scrubbing pads | Scratch surface | Use soft sponges only |

| Oil residue | Accelerates oxidation | Wipe and dry after use |

| Storage | Avoid folding | Keep flat to prevent cracking |

What Are the Limitations of Microwave Heating?

Silicone itself is microwave-safe, but problems occur when the product traps steam or has metallic inserts. Always design venting paths for enclosed shapes, and verify compatibility before certification.

While silicone is microwave-transparent, the food inside might not be. In one test, melting butter in a silicone bowl created localized “hot spots” where the fat temperature exceeded 250°C—far above the water boiling point. This intense, localized heat caused the silicone surface to bubble and whiten, damaging the container permanently.

Conclusion

Silicone’s safety and service life depend on how it is designed, processed, and maintained. Understanding each appliance’s thermal environment and applying proper validation ensures kitchen products that stay safe and durable for years.

References

[1]: Can Silicone Go in the Oven? – Cook’n’Chic

[2]: Thermal Ageing of Silicone Rubber – Advanced Materials

[3]: Characteristic properties of Silicone Rubber Compounds – Shin-Etsu