Manufacturers struggle with liner selection for adhesive silicone sheets, often experiencing release problems, adhesive transfer issues, and application difficulties. Poor liner choices lead to production delays, wasted materials, and compromised product performance that frustrate both producers and end-users.

The best backing liners for adhesive silicone sheets include polyethylene-coated kraft paper (offering balanced release force of 20-45 g/in), PET films (providing dimensional stability with <0.5% shrinkage), polyethylene films (offering moisture resistance up to 85% RH), and specialized silicone-coated release papers (allowing precise release force tailoring between 10-100 g/in depending on application requirements).

After helping dozens of clients optimize their adhesive silicone products, I’ve learned that backing liner selection is far more critical than most manufacturers realize. The right liner doesn’t just protect the adhesive—it fundamentally affects processing efficiency, application performance, and even end-user satisfaction. Let me share what I’ve discovered about selecting the perfect backing liner for your specific application.

Why Is Backing Liner Selection Critical for Adhesive Silicone Sheets?

Product developers often treat backing liners as an afterthought, focusing primarily on the silicone and adhesive formulations. This oversight leads to processing difficulties, inconsistent product performance, and application problems that could have been avoided with proper liner selection.

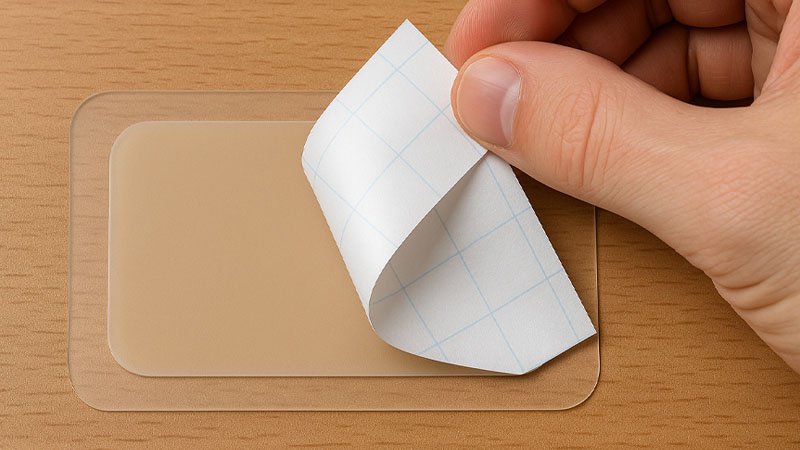

Backing liners serve multiple critical functions including protecting the adhesive layer from contamination, providing dimensional stability during processing and storage, controlling release characteristics during application, and in some cases, contributing to the final product’s functional properties. The right liner choice dramatically impacts both manufacturing efficiency and end-use performance.

The Multi-Functional Role of Backing Liners

I recently visited a client’s manufacturing facility where they were experiencing significant waste during their baby product assembly process. Their adhesive silicone components were difficult to handle, with inconsistent release and frequent adhesive transfer issues. After analyzing their process, I discovered they were using a standard liner that was completely mismatched to their specific adhesive formulation.

Backing liners perform several crucial functions that directly impact product quality:

Protection and Preservation

The primary function of any backing liner is protection:

- Creates a physical barrier against dust, moisture, and contaminants

- Prevents adhesive degradation from environmental exposure

- Maintains adhesive performance during storage and shipping

The effectiveness of this protection varies dramatically between liner types. For example, kraft paper liners typically offer good protection against dust but limited moisture resistance, while polyester films provide excellent barrier properties against both moisture and gases.

Release Functionality

Perhaps the most critical function is controlled release:

- Enables clean separation between liner and adhesive

- Provides consistent release force across the entire sheet

- Maintains adhesive integrity during the release process

Release characteristics must be precisely matched to both the adhesive formulation and the application method. Too easy release can cause premature separation during processing, while too tight release can lead to adhesive transfer problems or liner tearing.

Dimensional Stability

During processing, liners must maintain their dimensions:

- Prevents curling, warping, or distortion during manufacturing

- Ensures accurate die-cutting and converting operations

- Maintains registration for printed or patterned adhesives

Materials like polyester (PET) film offer excellent dimensional stability with typical shrinkage less than 0.1% under normal processing conditions, while some paper liners may experience dimensional changes of 1-2% with humidity variations.

Processing Compatibility

The liner must work seamlessly with manufacturing equipment:

- Withstands tension and mechanical stresses during converting

- Performs consistently at production speeds

- Resists heat during lamination or curing processes

For high-speed production, liners with high tensile strength and good temperature resistance are essential to prevent breaks and maintain productivity.

End-User Experience

Finally, the liner affects the customer experience:

- Ease of removal impacts application satisfaction

- Clear removal instructions may be printed directly on liners

- Some applications require liner removal in specific patterns or stages

For medical applications, liner design often incorporates tabs or special features to facilitate aseptic application techniques.

What Are the Primary Backing Liner Materials for Silicone Adhesives?

Manufacturers often default to basic paper liners without considering alternatives that might better suit their specific application. This limited approach results in suboptimal performance, processing difficulties, and missed opportunities to enhance product functionality.

The main backing liner materials for adhesive silicone sheets include kraft papers with various coatings (offering economical solutions with good convertibility), polyester (PET) films (providing superior dimensional stability and moisture resistance), polyethylene and polypropylene films (offering excellent conformability and moisture barriers), and specialty materials like fluoropolymer liners for the most demanding applications.

Comparing Liner Material Options

When I helped a client select new liners for his baby care products, we tested five different materials before finding the perfect match. The right choice dramatically reduced waste and improved application consistency for their end users—parents who needed reliable, easy-to-apply products for their babies.

Let’s examine the primary liner materials and their characteristics:

Paper-Based Liners

Paper remains the most widely used liner material due to its versatility and cost-effectiveness:

- Supercalendered Kraft (SCK)

- Smooth, dense paper with controlled porosity

- Good dimensional stability (typically 0.5-1.5% change with humidity)

- Economical choice for many applications

- Release force range: 30-60 g/in with standard silicone coating

- Polyethylene-Coated Kraft (PCK)

- Paper with polyethylene layer for improved moisture resistance

- Better dimensional stability than uncoated papers

- Good balance of performance and economy

- Release force range: 20-45 g/in with standard silicone coating

- Clay-Coated Kraft (CCK)

- Premium paper with mineral coating for smoothness

- Excellent printability for instructions or branding

- Superior caliper consistency compared to standard kraft

- Release force range: 25-50 g/in with standard silicone coating

| Paper Liner Type | Moisture Resistance | Dimensional Stability | Relative Cost | Best Applications |

|---|---|---|---|---|

| SCK | Low-Medium | Fair | $ | General purpose, indoor use |

| PCK | Medium | Good | $$ | Moderate humidity environments |

| CCK | Medium | Good | $$ | Applications requiring printing |

Film-Based Liners

Polymer films offer superior performance for demanding applications:

- Polyester (PET) Film

- Outstanding dimensional stability (<0.1% change)

- Excellent moisture and chemical resistance

- High tensile strength for high-speed processing

- Release force range: 15-40 g/in with standard silicone coating

- Polyethylene Film

- Excellent conformability and flexibility

- Good moisture barrier properties

- Lower cost than PET with good performance

- Release force range: 10-30 g/in with standard silicone coating

- Polypropylene Film

- Good balance of stiffness and flexibility

- Excellent chemical resistance

- Clear options available for see-through applications

- Release force range: 15-35 g/in with standard silicone coating

| Film Liner Type | Moisture Resistance | Dimensional Stability | Relative Cost | Best Applications |

|---|---|---|---|---|

| PET | Excellent | Excellent | $$$ | Precision applications, harsh environments |

| Polyethylene | Very Good | Good | $$ | Flexible applications, moisture concerns |

| Polypropylene | Very Good | Very Good | $$ | Chemical exposure, clear liner needs |

Specialty Liners

For the most demanding applications, specialty liners offer unique properties:

- Fluoropolymer Films

- Exceptional release properties for aggressive adhesives

- Outstanding chemical and temperature resistance

- Ultra-low surface energy for clean release

- Release force range: 5-20 g/in without additional coating

- Structured Release Liners

- Embossed or textured surface patterns

- Controls adhesive contact and air release

- Facilitates easier handling and application

- Release force can be mechanically controlled through texture

- Multi-Layer Composite Liners

- Combines benefits of different materials

- Can incorporate functional features (tear strips, etc.)

- Customized for specific application requirements

- Release properties can be precisely engineered

How Do Release Coatings Affect Silicone Adhesive Performance?

Manufacturers often focus solely on the base liner material while overlooking the critical role of release coatings. This incomplete approach leads to inconsistent release performance, adhesive transfer problems, and compromised adhesive properties that affect end-product functionality.

Release coatings fundamentally determine how the liner interacts with silicone adhesives, with options including silicone-based coatings (offering release forces from 10-100 g/in), fluorosilicone systems (providing controlled release for aggressive silicone adhesives), non-silicone alternatives (eliminating silicone contamination concerns), and differential coatings (creating intentionally different release levels on each side of a liner).

Engineering the Perfect Release Interface

The science of release coatings transformed our approach at RuiYang Silicone. When developing medical-grade silicone adhesive sheets, we discovered that the release coating chemistry was actually migrating into our adhesive, affecting its performance on skin. Switching to a specialized fluorosilicone coating solved the problem and improved patient comfort.

Let’s explore how release coatings work and how they affect adhesive performance:

Silicone Release Coatings

The most common release systems for silicone adhesives:

- Premium Silicone Coatings

- Platinum-catalyzed systems for consistent performance

- Minimal transfer to adhesive surface

- Precise control of release force

- Typical coating weight: 0.8-1.2 g/m²

- Standard Silicone Coatings

- Cost-effective tin-catalyzed systems

- Good performance for general applications

- Moderate release force control

- Typical coating weight: 1.0-1.5 g/m²

- Modified Silicone Systems

- Engineered for specific release profiles

- Can be formulated for easy or tight release

- Often modified with additives for special properties

- Typical coating weight: 0.8-1.8 g/m²

Fluorosilicone Release Systems

Specialized coatings for demanding silicone adhesives:

- Provides reliable release from aggressive silicone adhesives

- Resists the natural affinity between silicone adhesives and silicone release coatings

- Higher cost but solves difficult release problems

- Typical coating weight: 1.0-1.5 g/m²

Fluorosilicone coatings are essential when working with high-tack silicone adhesives that would otherwise bond too strongly to standard silicone release coatings.

Non-Silicone Alternatives

For silicone-sensitive applications:

- Eliminates silicone contamination concerns

- Based on polyacrylates, polyolefins, or other chemistries

- May offer specialized performance characteristics

- Typical coating weight varies by chemistry

These systems are critical in electronics, automotive painting, and other applications where silicone contamination must be avoided.

Release Force Engineering

The science of controlling exactly how a liner separates from adhesive:

- Release Force Measurement

- Typically measured in grams per inch (g/in) or grams per centimeter (g/cm)

- Measured at specific peel angles (usually 180° or 90°)

- Affected by peel speed and temperature

- Release Force Factors

- Coating chemistry and formulation

- Coating weight and curing conditions

- Base liner surface characteristics

- Adhesive properties and contact time

- Differential Release

- Intentionally different release levels on each side of a liner

- Facilitates roll unwinding and converting operations

- Typical differential: 2:1 to 5:1 between tight and easy sides

| Release Coating Type | Release Force Range | Silicone Adhesive Compatibility | Relative Cost | Best Applications |

|---|---|---|---|---|

| Standard Silicone | 20-60 g/in | Good | $$ | General purpose |

| Premium Silicone | 10-100 g/in | Very Good | $$$ | Precision applications |

| Fluorosilicone | 15-50 g/in | Excellent | $$$$ | Aggressive silicone adhesives |

| Non-Silicone | 30-80 g/in | Fair-Good | $$$ | Silicone-sensitive environments |

What Environmental Factors Affect Backing Liner Performance?

Companies often store and process adhesive silicone sheets without considering how environmental conditions affect liner performance. This oversight leads to unexpected release problems, dimensional instability, and adhesive degradation that compromise product quality and increase waste.

Environmental factors significantly impact backing liner performance, with humidity being the most critical (affecting dimensional stability by 0.5-2% per 20% RH change for paper liners), followed by temperature (altering release force by 10-30% per 10°C change), UV exposure (degrading both liner and adhesive), and storage time (potentially increasing release force by 20-50% over 6-12 months through adhesive wetting).

Controlling the Variables for Consistent Performance

Environmental control made a dramatic difference for a client’s company. Their production facility in the southern United States experienced significant seasonal humidity variations that affected their paper-based liners. After implementing environmental controls and switching to moisture-resistant liners, their production consistency improved dramatically across all seasons.

Let’s examine how environmental factors affect backing liner performance:

Humidity Effects

Moisture in the air significantly impacts liner behavior:

- Dimensional Changes

- Paper liners: Typically 0.5-2% dimension change per 20% RH change

- Film liners: Generally <0.1% dimension change regardless of humidity

- Composite liners: Performance depends on construction

- Curl and Warp

- Unbalanced moisture absorption causes differential expansion

- More pronounced with paper-based liners

- Can create handling difficulties in automated equipment

- Release Performance Changes

- Moisture can affect release coating cure and performance

- High humidity may increase release force with some coatings

- Moisture barrier properties become critical in high-humidity environments

Temperature Considerations

Temperature affects both physical properties and release characteristics:

- Release Force Variation

- Generally decreases with higher temperatures

- Typical change: 10-30% per 10°C temperature change

- More pronounced with certain silicone release systems

- Dimensional Effects

- Thermal expansion varies significantly between materials

- PET film: ~17 ppm/°C linear expansion

- Paper: Varies but generally less affected by temperature than humidity

- Adhesive Interaction

- Higher temperatures accelerate adhesive wetting of release surface

- Can increase release force over time at elevated temperatures

- May affect adhesive transfer characteristics

UV and Light Exposure

Often overlooked but potentially significant:

- UV degradation of both liner and release coating

- Potential color changes in paper-based liners

- Possible release performance deterioration

- Some adhesives become more aggressive with UV exposure

For products stored or displayed in high-light environments, UV-stabilized materials may be necessary.

Storage Duration and Conditions

Time affects the liner-adhesive relationship:

- Increasing Release Force

- Adhesive continues to wet the release surface over time

- Can increase release force by 20-50% over 6-12 months

- More pronounced with higher storage temperatures

- Blocking in Rolls

- Adjacent layers may bond during extended storage

- More likely with high pressure, high temperature, or high humidity

- Can cause liner damage during unwinding

- Chemical Aging Effects

- Migration of components between adhesive and release coating

- Potential crosslinking or degradation of release system

- Changes in adhesive performance due to contamination

| Environmental Factor | Paper Liner Sensitivity | Film Liner Sensitivity | Mitigation Strategies |

|---|---|---|---|

| Humidity | High | Low | Climate control, moisture-resistant liners |

| Temperature | Medium | Medium | Temperature-controlled storage, thermal stabilization |

| UV Exposure | High | Medium | Opaque packaging, UV-stabilized materials |

| Storage Duration | Medium-High | Medium | Inventory rotation, optimized release systems |

How Should Backing Liners Be Selected for Specific Applications?

Engineers often select backing liners based on habit or availability rather than application-specific requirements. This generic approach results in suboptimal performance, unnecessary costs, and missed opportunities to enhance product functionality through strategic liner selection.

Backing liner selection should be driven by application requirements including removal method (manual vs. automated, affecting release force targets), environmental exposure conditions, regulatory considerations (particularly for medical and food applications), cost constraints, and sustainability goals. The ideal liner balances these factors while providing reliable performance throughout the product lifecycle.

Matching Liners to Application Needs

Finding the perfect liner match transformed a challenging project for one of our medical clients. They were developing silicone adhesive sheets for advanced wound care but experiencing inconsistent application results. By analyzing their specific application requirements—including sterile application techniques, extended wear time, and sensitive skin compatibility—we developed a custom liner system that dramatically improved clinical outcomes.

Here’s how to select the right backing liner for specific applications:

Medical and Healthcare Applications

For products contacting skin or used in healthcare settings:

- Wound Care Products

- Clean-removing liners that leave no residue

- Often require differential release for layered application

- May need printed application instructions

- Typically use PET or PCK liners with premium silicone coatings

- Wearable Medical Devices

- Precision die-cut liners with tabs or removal aids

- Dimensional stability critical for registration with device components

- May require sterilization compatibility

- Often use PET liners with controlled release properties

- Surgical Drapes and Films

- Aseptic removal techniques require specialized liner designs

- Often incorporate multiple liner segments for sequential application

- Must maintain sterile field during application

- Typically use PET or specialized composite liners

Industrial and Technical Applications

For manufacturing, assembly, and technical products:

- Gaskets and Seals

- High dimensional stability for precise positioning

- Often require robust liners that resist tearing during complex die-cuts

- May need chemical resistance for harsh environments

- Typically use PET or polypropylene liners

- Electronic Applications

- Require anti-static properties to protect sensitive components

- Often need silicone-free liners to prevent contamination

- May require clean room compatible materials

- Typically use specialized films with non-silicone release systems

- Automotive and Aerospace

- Temperature resistance for processing and end-use environments

- Often require liners compatible with automated application equipment

- May need outdoor durability for construction phases

- Typically use robust film liners with stable release characteristics

Consumer Product Applications

For retail and consumer-facing products:

- Baby Care Products

- Easy release for caregivers managing active children

- Often require printed instructions directly on liner

- Need safe materials free from concerning chemicals

- Typically use PCK or PET liners with gentle release

- Retail Packaging

- May incorporate branding and marketing information on liner

- Often need transparency for product visibility

- Require consumer-friendly removal

- Typically use clear films or printed paper liners

- Home and Personal Care

- Must function across varying consumer application techniques

- Often require water and bathroom environment resistance

- Need consistent performance despite rough handling

- Typically use moisture-resistant films or coated papers

Sustainability Considerations

Increasingly important across all applications:

- Recyclable Liner Options

- PET liners: Widely recyclable in established streams

- Paper liners: Recyclable but may require silicone removal

- Emerging compostable and biodegradable options

- Reduced Material Usage

- Thinner liners with maintained performance

- Right-sized liners that minimize waste

- Optimized release that requires less material

- End-of-Life Considerations

- Separability of components for proper disposal

- Clear consumer instructions for proper recycling

- Design for circular economy principles

| Application Type | Recommended Liner Types | Key Performance Requirements | Typical Release Force |

|---|---|---|---|

| Medical/Wound Care | PET, PCK with premium silicone | Clean removal, precision | 20-40 g/in |

| Industrial Gaskets | PET, Polypropylene | Dimensional stability, tear resistance | 40-70 g/in |

| Electronics | Specialty films, non-silicone | Contamination control, anti-static | 30-50 g/in |

| Baby Products | PCK, PET with gentle release | Easy removal, safety | 15-30 g/in |

| Automotive | Robust films, heat-resistant | Temperature stability, automation | 30-60 g/in |

Conclusion

Selecting the right backing liner for adhesive silicone sheets requires careful consideration of material properties, release characteristics, environmental factors, and application requirements. By understanding the critical role liners play in both manufacturing efficiency and end-use performance, manufacturers can optimize their products for reliability, user satisfaction, and cost-effectiveness. The ideal liner isn’t merely a disposable component—it’s an engineered element that significantly contributes to overall product success.