Silicone sheets may look durable—but compression forces can silently reduce their long-term performance.

Compression set testing measures how much a silicone sheet fails to return to its original thickness after being compressed for a period of time under specific conditions.

I’ve seen products that look perfect after molding but fail after a few weeks of real-world use. In most cases, it’s due to poor compression recovery. That’s why compression set testing is a key part of our quality assurance process.

What is compression set in silicone sheets?

It’s what happens when silicone gets squished—and doesn’t bounce back.

Compression set is the permanent deformation of a silicone sheet after prolonged compressive stress. It tells us how much of its shape the silicone loses.

When you compress a silicone gasket, mat, or pad and then release it, the material should return to its original thickness. If it doesn’t, it means the sheet has taken a compression set. This is especially critical in sealing or cushioning applications.

In one project, we used a low-quality sheet for a baby bottle sealing ring. After two weeks under lid pressure, the ring flattened and leaked. The cause? High compression set.

Why is compression set important in silicone products?

A high compression set means the silicone will fail to perform over time.

Compression set affects sealing, durability, and product safety—especially in gaskets, cushioning pads, and baby products under pressure.

If a silicone part stays compressed, it can’t maintain pressure, seal out moisture, or absorb impact effectively. That’s why compression set is tested in industries like:

- Automotive – Gaskets and seals

- Baby care – Bottle seals, teethers

- Medical – Skin-contact pressure devices

- Electronics – Shock-absorbing silicone pads

In my experience, even a 5% change in compression set can make or break a product that needs to last six months or more under load.

How is silicone sheet compression set tested?

This test follows clear steps set by ASTM standards.

Compression set is tested by compressing a silicone sheet at a set temperature for a defined time, then measuring the thickness recovery after rest.

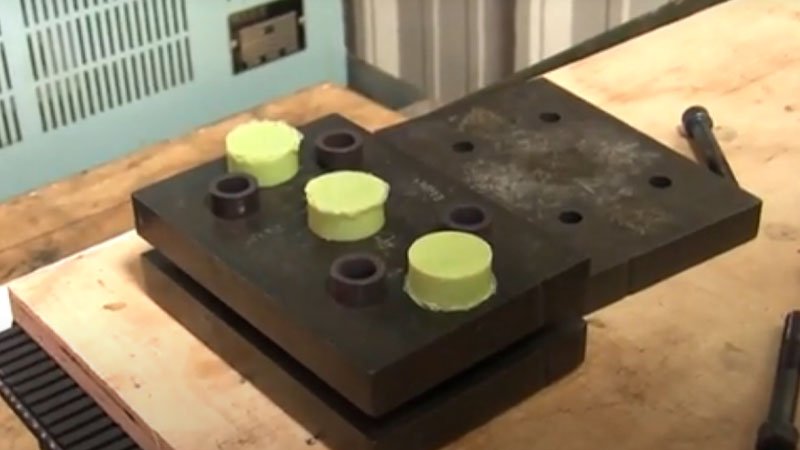

We follow ASTM D395 – the standard test method for rubber property—compression set. Here’s how it works:

| Step | Description |

|---|---|

| Sample Prep | Cut sample (e.g., 12.5 mm thick × 29 mm diameter) |

| Initial Measurement | Measure the original thickness (T₀) |

| Compression | Compress to 75% of thickness for 22–70 hours |

| Temperature Control | Place in oven at 70°C, 100°C, or 125°C |

| Rest Period | Remove and allow to cool for 30 mins |

| Final Measurement | Measure recovered thickness (T₁) |

| Calculation | Use formula below |

Compression Set (%) = [(T₀ – T₁) / (T₀ – Tn)] × 100

Where Tn is the compressed thickness (75% of T₀).

For example:

- T₀ = 10 mm

- Compressed to 7.5 mm

- After recovery, T₁ = 8.5 mm

- Compression Set = [(10 – 8.5) / (10 – 7.5)] × 100 = 60%

That means 60% of the compression was not recovered. That’s high. We aim for under 25% in most applications.

What factors influence the compression set of silicone?

Not all silicone behaves the same.

Compression set depends on silicone grade, crosslinking structure, fillers, temperature, and thickness.

Several variables affect how well a silicone sheet bounces back:

1. Silicone Grade

- High-consistency rubber (HCR) tends to recover better than liquid silicone rubber (LSR).

- Food-grade silicone may have more flexibility but a slightly higher set.

2. Crosslinking Type

- Peroxide-cured silicones often resist set better than platinum-cured ones.

3. Fillers and Additives

- High filler content can reduce elasticity.

- Reinforcing agents may improve short-term performance but worsen recovery.

4. Temperature Exposure

- Higher test temperatures cause more permanent deformation.

- Always match the testing condition to the product’s real use.

5. Sheet Thickness

- Thin sheets recover faster.

- Thick sheets store more energy and are more prone to setting.

We always test under multiple conditions—especially for baby products that need to handle boiling, sterilization, and mechanical stress over months.

How to improve compression set resistance in silicone sheets?

The solution starts before production.

Choose the right silicone formulation, curing method, and sheet design to improve resistance to compression set.

Here are key strategies we use:

- Material Selection – Use high-performance or fluorosilicone for heat-sensitive applications.

- Optimize Curing – Proper vulcanization reduces internal stress and improves elasticity.

- Design Thickness – Avoid over-compression in actual use.

- Avoid Overheating – Silicone exposed to excessive heat during processing can pre-age.

- Post-Curing – Heat-treating after molding can improve recovery.

We once developed a sealing mat for a baby food warmer. By switching from standard silicone to a peroxide-cured medical-grade compound, we cut the compression set from 35% to just 15%—and the customer saw fewer product returns.

What compression set values are considered acceptable?

It depends on the product and industry.

Compression set below 20–25% is typically acceptable for most silicone sheet applications; critical applications may require under 10%.

Here’s a general guideline:

| Application | Ideal Compression Set (%) |

|---|---|

| Baby Products | ≤ 15% |

| Industrial Gaskets | ≤ 25% |

| Medical Devices | ≤ 10% |

| Electronics Pads | ≤ 20% |

| Food Contact Sheets | ≤ 20% |

Always ask for test reports from your supplier. At RuiYang, we test compression set as part of every new product validation. It’s not just about certification—it helps us predict how well the silicone will last in real use.

When should you request compression set testing from your supplier?

Right before it becomes a problem.

Always request compression set testing when developing silicone products that will be under pressure, heat, or long-term mechanical use.

If you’re developing any of the following, compression testing is a must:

- Silicone bottle seals

- Reusable baby feeding mats

- High-pressure industrial gaskets

- Silicone foam sheets for cushioning

- Medical-grade skin adhesives

One of our U.S. clients asked for custom teething pads. We ran compression tests across different hardness levels to help them choose the best balance between softness and long-term durability. That’s the power of data.

Conclusion

Compression set testing shows how well silicone sheets keep their shape under pressure—making it essential for long-lasting, reliable products.