Manufacturers constantly struggle with finding silicone sheets in the right dimensions for their projects. Ordering custom sizes causes production delays, while using incorrect thicknesses leads to product failures and wasted materials.

Industrial silicone sheets typically come in thicknesses ranging from 0.5mm to 20mm, with standard widths of 1000mm and 1200mm. Sheet lengths vary from 5 to 10 meters for roll stock, while pre-cut sheets are commonly available in dimensions of 1000mm x 1000mm and 1200mm x 1200mm.

After supplying silicone materials to countless industrial clients over the years, I’ve noticed that understanding standard dimensions is crucial for efficient project planning. Let me walk you through the common thicknesses and sizes you’ll encounter, so you can make informed decisions for your specific applications.

What Thickness Options Are Available for Industrial Silicone Sheets?

Engineers often select inappropriate sheet thickness, resulting in either excessive material use or insufficient performance. This common mistake leads to increased costs and potential product failures.

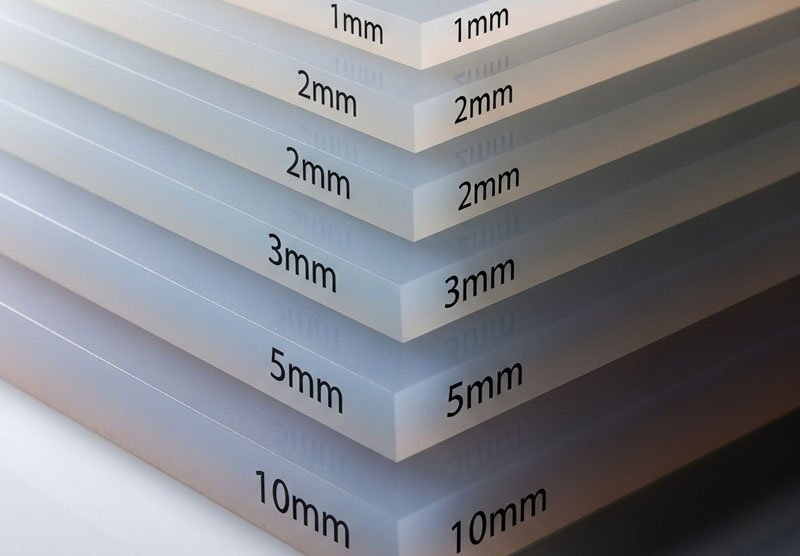

Standard silicone sheet thicknesses range from ultra-thin 0.5mm sheets to heavy-duty 20mm options. The most commonly stocked thicknesses are 1mm, 2mm, 3mm, 5mm, and 10mm, with incremental options available for specialized applications.

Finding Your Perfect Thickness

Selecting the right silicone sheet thickness is one of the most critical decisions in any industrial application. I remember working with John from Little Steps Baby Care last year when he was developing a new line of baby products. He initially ordered 5mm sheets for gaskets in their bottle warmers, only to discover that 2mm sheets provided the perfect compression while using less material.

The thickness you choose directly impacts performance characteristics like compression resistance, flexibility, and insulation properties. Here’s a breakdown of common thickness ranges and their typical applications:

Ultra-Thin Sheets (0.5mm – 0.8mm)

These delicate sheets excel in applications requiring minimal space and high flexibility. They’re perfect for electrical insulation, thin gaskets, and membrane switches. While handling these sheets requires care, they provide excellent conformability to irregular surfaces.

Standard Thin Sheets (1mm – 2mm)

This is our most popular thickness range, accounting for approximately 40% of our industrial sales. These sheets balance flexibility with durability and are commonly used for general gaskets, seals, and protective linings. They’re easy to cut and form while still providing reliable performance.

Medium Thickness Sheets (3mm – 5mm)

When applications demand greater compression resistance and durability, medium thickness sheets are the go-to choice. They’re commonly used in vibration dampening, cushioning applications, and more demanding gasket requirements. These sheets maintain good flexibility while offering enhanced mechanical properties.

| Thickness | Typical Applications | Compression Characteristics |

|---|---|---|

| 0.5mm – 0.8mm | Electrical insulation, thin gaskets | Minimal compression resistance, high flexibility |

| 1mm – 2mm | General gaskets, seals, linings | Moderate compression, good flexibility |

| 3mm – 5mm | Vibration dampening, cushioning | Good compression resistance, moderate flexibility |

| 6mm – 10mm | Heavy-duty seals, impact protection | High compression resistance, limited flexibility |

| 12mm – 20mm | Specialized cushioning, extreme insulation | Maximum compression resistance, minimal flexibility |

Thick Sheets (6mm – 10mm)

These robust sheets provide significant compression resistance and are ideal for heavy-duty seals, impact protection, and applications requiring substantial material thickness. While less flexible than thinner options, they offer superior durability in demanding environments.

Extra-Thick Sheets (12mm – 20mm)

Reserved for specialized applications, these extremely thick sheets provide maximum compression resistance and insulation properties. They’re commonly used in high-pressure sealing, extreme thermal insulation, and specialized cushioning applications where substantial material volume is required.

Custom thicknesses beyond these standard ranges are available through special order, though they typically involve minimum quantity requirements and longer lead times. For most industrial applications, standard thicknesses provide the optimal balance of performance and availability.

How Do Standard Sheet Dimensions Impact Material Utilization and Cost?

Ordering non-standard silicone sheet sizes often results in significant material waste and higher costs. Many buyers don’t realize that working within standard dimensions can reduce expenses by 15-30%.

Standard silicone sheets are typically supplied in widths of 1000mm and 1200mm, with roll lengths ranging from 5 to 10 meters. Pre-cut sheets are commonly available in dimensions of 1000mm x 1000mm and 1200mm x 1200mm, with custom cutting services available for specific requirements.

Maximizing Material Efficiency

Understanding standard silicone sheet dimensions has saved our clients thousands of dollars in material costs over the years. I recently consulted with a manufacturing company that was ordering custom-cut 900mm x 900mm sheets for their production. By redesigning their cutting pattern to work with standard 1000mm x 1000mm sheets, they reduced material waste by 22% and lowered their overall costs significantly.

Silicone sheets are typically manufactured in continuous processes that produce standard widths, which are then either sold as roll stock or cut into standard sheet sizes. These dimensions are optimized for production efficiency and material utilization.

Standard Roll Stock Dimensions

Roll stock is the most economical option for high-volume users and offers the greatest flexibility for custom cutting. Standard roll widths include:

- 1000mm (39.37 inches) – The most common width for general industrial applications

- 1200mm (47.24 inches) – Preferred for larger applications and more efficient cutting of multiple smaller pieces

- 915mm (36 inches) – Common in regions using imperial measurements

Roll lengths typically range from 5 to 10 meters, with 10-meter rolls being the standard for most industrial suppliers. Some specialty thicknesses may be limited to shorter roll lengths due to manufacturing constraints.

Pre-Cut Sheet Dimensions

For convenience and smaller applications, pre-cut sheets are available in standard dimensions:

| Sheet Size | Common Applications | Availability |

|---|---|---|

| 1000mm x 1000mm | General industrial use, medium-sized gaskets | High – Stock item |

| 1200mm x 1200mm | Larger gaskets, industrial curtains | High – Stock item |

| 500mm x 500mm | Small parts, sample testing | Moderate – Common cut size |

| 2000mm x 1000mm | Large gaskets, equipment linings | Limited – Special order |

Custom Sizing Options

While standard dimensions are most economical, custom sizing services are available through several methods:

- Factory cutting – For large orders, manufacturers can cut to custom widths during production

- Distributor services – Many suppliers offer cutting services for custom dimensions

- Water jet cutting – Precision cutting for complex shapes and tight tolerances

- Die cutting – Economical for high-volume production of identical pieces

When planning projects requiring silicone sheets, I always recommend starting with standard dimensions and working backward to determine the most efficient cutting pattern. This approach minimizes waste and often reduces overall project costs by 15-30% compared to ordering custom dimensions.

What Factors Influence Tolerance and Dimensional Stability in Silicone Sheets?

Manufacturing processes and material properties create dimensional variations in silicone sheets. Without understanding these tolerances, engineers risk designing components that won’t fit properly during assembly.

Standard silicone sheets typically have thickness tolerances of ±10% for sheets under 3mm and ±5% for thicker sheets. Width and length tolerances generally range from ±1% to ±2%, with tighter tolerances available for premium grades or specialized applications.

Engineering with Realistic Expectations

Understanding dimensional tolerances in silicone sheets is crucial for successful engineering projects. I’ve seen numerous cases where designers specified exact dimensions without accounting for the natural variability of silicone materials. One memorable example was a medical device manufacturer who designed gaskets with 0.01mm precision, only to discover that standard silicone sheet production simply couldn’t maintain such tight tolerances.

Silicone, being an elastomeric material, has inherent dimensional variability that stems from several factors:

Manufacturing Process Influences

The production method significantly impacts dimensional stability and tolerances:

- Calendering – This common process produces sheets by passing raw silicone through precision rollers. While efficient, it typically yields thickness tolerances of ±10% for thin sheets.

- Compression Molding – This method can achieve tighter tolerances (±5%) but is more costly and typically used for specialized applications.

- Extrusion – Primarily used for continuous production of thinner sheets, with typical tolerances of ±8-12%.

Material Formulation Factors

The specific silicone formulation directly affects dimensional stability:

| Formulation Type | Dimensional Stability | Typical Applications |

|---|---|---|

| General Purpose | Moderate | Standard industrial gaskets |

| High-Durometer (70+ Shore A) | Good | Precision components, structural parts |

| Reinforced (Fiberglass/Fabric) | Excellent | Critical sealing, dimensional stability |

| Foam/Sponge | Poor to Fair | Cushioning, non-critical dimensions |

Standard Tolerance Expectations

For practical engineering purposes, these tolerance ranges represent industry standards:

- Thickness Tolerance:

- Sheets under 3mm: ±10%

- Sheets 3mm-10mm: ±5-7%

- Sheets over 10mm: ±5%

- Width/Length Tolerance:

- Standard grades: ±1-2%

- Premium grades: ±0.5-1%

- Flatness/Warpage:

- Standard grades: 2-3% of length

- Premium grades: 1% of length

When designing components using silicone sheets, I always recommend incorporating these tolerances into your specifications. For applications requiring tighter tolerances, secondary processing such as precision grinding can achieve ±3% thickness tolerance, though at additional cost.

It’s also important to consider that silicone materials can experience dimensional changes due to temperature fluctuations, with typical thermal expansion coefficients of 2-4 × 10^-4 per °C. This becomes particularly relevant in applications involving significant temperature variations.

Conclusion

Understanding standard silicone sheet thicknesses and dimensions is essential for cost-effective project planning. By working with common sizes (0.5-20mm thickness and standard widths of 1000-1200mm), you’ll minimize waste, reduce costs, and ensure your industrial applications perform as expected.