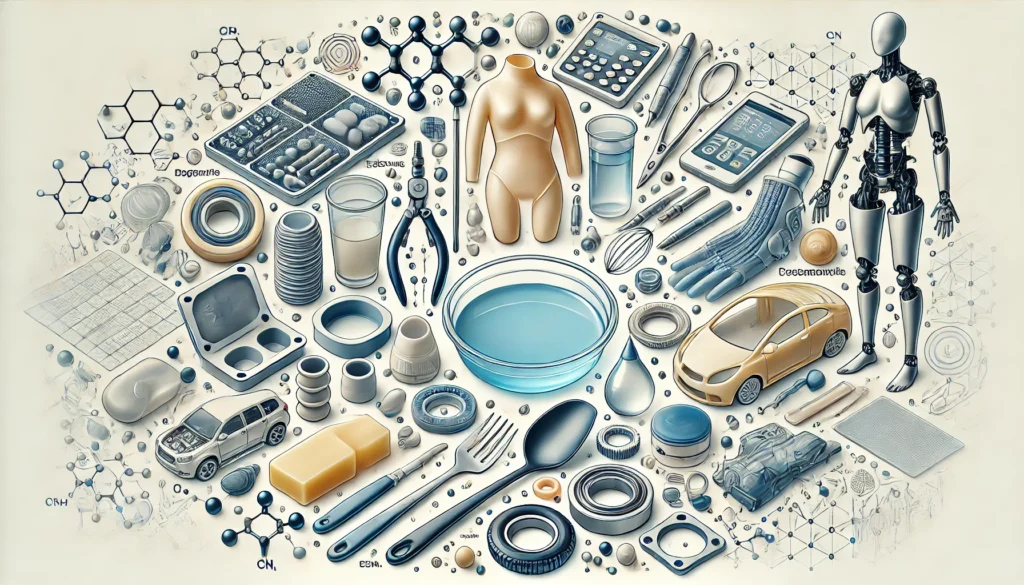

Are you curious why silicone is a preferred material in various industries? Imagine a substance that combines durability, flexibility, and elasticity. This might sound too good to be true, but silicone offers precisely these attributes. It’s essential in everything from medical devices to kitchen utensils. The secret to its versatility lies in its unique chemical structure.

Silicone’s elasticity and flexibility make it an invaluable material across many sectors. These properties allow silicone to stretch and compress without permanent deformation, making it ideal for applications requiring durability and adaptability.

So, what makes silicone so special? Keep reading to uncover the science behind its remarkable properties and how they revolutionize everyday products.

Why is Silicone So Elastic and Flexible?

Silicone’s elasticity stems from its unique molecular structure. The backbone of silicone consists of alternating silicon and oxygen atoms, forming a flexible and stable chain. This structure allows the molecules to move easily, giving silicone its remarkable stretchability.

What Are the Benefits of Silicone’s Flexibility?

Flexibility in silicone materials means they can bend without breaking. This characteristic is crucial for applications where materials are subjected to stress and movement. For example, silicone gaskets and seals benefit from this flexibility, ensuring a tight seal under varying pressure conditions.

How Does Silicone’s Elasticity Enhance Its Applications?

- Medical Devices: Silicone is used in prosthetics and implants due to its ability to mimic the elasticity of human tissue. This ensures comfort and functionality for patients.

- Consumer Products: In items like kitchenware, silicone’s elasticity ensures longevity and resilience against heat and deformation.

Why Choose Silicone for High-Temperature Applications?

Silicone can withstand extreme temperatures without losing its properties. Its stability in high and low temperatures makes it ideal for automotive and aerospace industries.

What Makes Silicone Durable?

Silicone’s chemical stability ensures that it resists environmental factors like UV light, ozone, and moisture. This durability is why silicone is a preferred choice for outdoor applications and long-term use.

How Does Silicone’s Flexibility Contribute to Safety?

In medical and food applications, flexibility ensures that silicone products can be sterilized without losing their shape or properties. This safety aspect is critical in maintaining hygiene standards.

Can Silicone’s Flexibility Reduce Costs?

Yes, because silicone’s flexibility leads to less material fatigue and longer life spans, it reduces replacement and maintenance costs. Industries save money by investing in durable, long-lasting materials.

What Are the Limitations of Silicone’s Flexibility?

While silicone is flexible, it does have its limits. It can tear under excessive force, and certain chemicals can degrade its structure. Understanding these limitations is crucial for proper application and longevity.

How Is Silicone Modified for Enhanced Performance?

Manufacturers often add fillers or reinforce silicone with fibers to enhance its properties. These modifications can increase silicone’s elasticity, strength, and resistance to environmental factors, tailoring it for specific industrial needs.

How Does Silicone’s Elasticity Improve Consumer Products?

Silicone’s elasticity ensures that consumer products maintain their shape and function over time. Items like phone cases and bakeware benefit from silicone’s ability to return to its original form after stretching or compressing.

Why Is Silicone Preferred in the Food Industry?

In the food industry, silicone’s non-reactive and flexible nature makes it perfect for molds and containers. It can withstand oven temperatures and freezers without degrading or leaching harmful chemicals.

How Do Engineers Leverage Silicone’s Properties?

Engineers utilize silicone’s elasticity in designing components that need to absorb shocks or vibrations. This application is common in automotive and electronic industries where durability and reliability are paramount.

Can Silicone’s Flexibility Be a Drawback?

In some cases, too much flexibility can be a disadvantage. For instance, in structural applications, materials with higher rigidity might be necessary. Balancing flexibility and rigidity is key in material selection.

Conclusion

Silicone’s elasticity and flexibility make it a standout material in various applications. From medical devices to kitchen tools, its ability to maintain shape and integrity under stress is unmatched. As technology advances, silicone’s role in innovative solutions continues to grow, proving its worth in modern industry.