Silicone rubber strips are crucial components known for their versatility and durability across various industries. They play an essential role in sealing, insulation, cushioning, and vibration damping applications, delivering top-notch performance under challenging conditions. Understanding the different types of silicone rubber strips available can help businesses make informed decisions based on their specific needs and applications. Join us as we delve into the various types of silicone rubber strips and their unique benefits in detail.

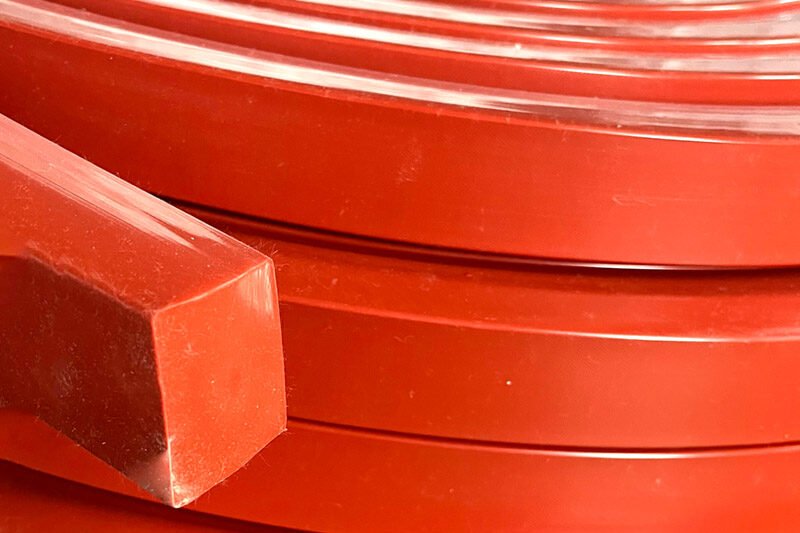

1. Solid Silicone Rubber Strips

Solid silicone rubber strips are noted for their dense, non-porous structure, which provides excellent resistance to extreme temperatures, UV radiation, and environmental elements. This type maintains its integrity and flexibility over a wide range of conditions, making it ideal for demanding sealing and gasketing applications.

Solid Silicone Rubber Strips Applications

- Industrial Sealing: Extensively used in industrial settings where robust sealing solutions are needed to prevent leaks and withstand harsh environments.

- Automotive Gaskets: Ensures reliable sealing in automotive engines, transmissions, and other critical components exposed to high temperatures and mechanical stress.

- Electronics: Provides insulation and protection against moisture and contaminants in electronic devices and control panels.

Solid silicone rubber strips are preferred for their durability, resilience, and ability to maintain sealing integrity under pressure. They come in various thicknesses and widths to meet specific project requirements.

2. Foam Silicone Rubber Strips

Foam silicone rubber strips feature a lightweight, cellular structure that provides excellent cushioning, vibration damping, and sealing properties. Unlike solid silicone, foam silicone rubber strips offer enhanced flexibility and conformability, making them ideal for applications requiring shock absorption and noise reduction.

Foam Silicone Rubber Strips Applications:

- HVAC Systems: Used for sealing and insulation in heating, ventilation, and air conditioning systems to reduce vibration and noise transmission.

- Electronics: Provides cushioning and protection in electronic devices, absorbing shocks and preventing damage from impacts.

- Packaging: Used as gaskets and seals in packaging machinery to ensure airtight and secure closures.

Foam silicone rubber strips are favored for their softness, resilience, and ability to conform to irregular surfaces. They come in different densities and thicknesses to meet specific performance requirements.

3. High-Consistency Silicone Rubber (HCR) Strips

High-consistency silicone rubber (HCR) strips are semi-solid materials known for their high tensile strength, tear resistance, and durability. This type retains its shape well and offers excellent performance in applications requiring repetitive use and resistance to deformation.

High-Consistency Silicone Rubber (HCR) Strips Applications:

- Medical Devices: Extensively used in healthcare for manufacturing medical-grade components due to its biocompatibility and sterilization capabilities.

- Food Processing Equipment: Provides reliable sealing in food-grade machinery, ensuring compliance with FDA regulations for safety and hygiene.

- Automotive Seals: Used in automotive applications where resistance to extreme temperatures, oils, and chemicals is essential for long-term performance.

High-consistency silicone rubber strips are available in a range of shore hardness levels to meet different sealing requirements. They are valued for their consistency, reliability, and ability to maintain sealing integrity.

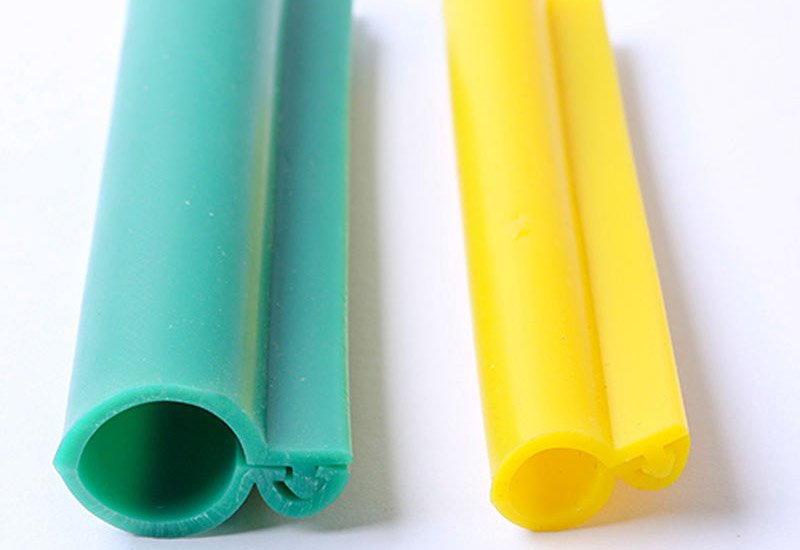

4. Liquid Silicone Rubber (LSR) Strips

Liquid silicone rubber (LSR) strips are formed from a liquid compound cured into solid silicone material. This process allows precise molding of intricate shapes, making LSR strips highly versatile for specialized applications.

Liquid Silicone Rubber (LSR) Strips Applications:

- Medical Devices: Used in the production of medical implants, surgical instruments due to its biocompatibility.

- Consumer Products: Preferred for baby products, kitchenware where softness is critical. Electronics: Provides sealing in electronic devices against moisture and mechanical stress.

Liquid silicone rubber strips offer exceptional flexibility, heat resistance making them ideal for precise molding applications. They come in different colors to meet specific aesthetic requirements.

Comparison of Different Types of Silicone Rubber Strips

This guide details the differences among various types of silicone rubber strips.

| Property / Type | Solid Silicone Rubber Strips | Foam Silicone Rubber Strips | High-Consistency Silicone Rubber Strips | Liquid Silicone Rubber Strips |

|---|---|---|---|---|

| Structure | Dense, non-porous | Lightweight, cellular | Semi-solid | Liquid |

| Temperature Resistance | Excellent high/low temp | Moderate | Excellent | Excellent |

| Hardness (Shore) | High (varies by grade) | Soft to medium | High (varies by grade) | Medium to high |

| Flexibility | Low to moderate | High | Low to moderate | High |

| Compression Set | Good | Moderate to good | Excellent | Excellent |

| Chemical Resistance | Good | Moderate | Excellent | Excellent |

| Applications | Industrial sealing/automotive gaskets | HVAC/electronics/packaging | Medical devices/food processing | Medical implants/consumer products |

| Customization Options | Limited | Moderate | Limited | High |

| Regulatory Compliance | Varies by grade | Varies by grade | FDA compliant | FDA compliant |

Key Considerations When Choosing Silicone Rubber Strips

When selecting silicone rubber strips for your applications consider several factors:

Temperature Resistance

Evaluate the temperature range the silicone rubber can withstand without compromising its sealing or mechanical properties. Solid silicone rubber typically offers broader temperature resistance compared to foam or LSR strips.

Material Hardness (Shore Hardness)

Consider the hardness level (shore hardness) of the silicone rubber strip, which affects its compression set, flexibility, and sealing efficiency. Solid and foam silicone rubber strips vary in hardness, with foam strips generally softer for cushioning applications.

Chemical Compatibility

Assess the silicone rubber’s resistance to chemicals, oils, solvents, and other substances present in your operating environment. High-consistency silicone rubber (HCR) and liquid silicone rubber (LSR) are known for their excellent chemical inertness.

Customization Options

Look for suppliers who offer customization options in terms of strip dimensions, colors, surface finishes, and special formulations tailored to your specific application requirements.

Regulatory Compliance

Ensure that the silicone rubber strips meet regulatory standards relevant to your industry, such as FDA compliance for food-grade applications or biocompatibility standards for medical devices.

Performance Requirements

Define the performance criteria, including durability, resilience, electrical insulation, and resistance to UV exposure or environmental factors, to match the strip’s capabilities with your application demands.

Conclusion

silicone rubber strips offer a range of properties and benefits that make them essential for various industrial, automotive, medical, and consumer applications. By understanding the specific attributes of solid, foam, high-consistency, and liquid silicone rubber strips, businesses can select the most suitable type for their needs. Key considerations such as temperature resistance, material hardness, chemical compatibility, customization options, and regulatory compliance are critical in ensuring optimal performance and longevity.

Related: