Ever had a device stop working just because of a little water or dust? The wrong keypad design can destroy a product’s reliability.

Silicone keypads achieve waterproof and dustproof performance using sealing ribs, compression design, and membrane overlays that block moisture and particles.

Many industries rely on silicone keypads to perform in tough environments. I’ve worked on sealing designs for medical, industrial, and outdoor equipment. Here’s how the best ones stay protected.

Why is Waterproofing & Dustproofing Important?

A product is only as strong as its weakest point. Ingress kills electronics fast.

Waterproof and dustproof silicone keypads prevent moisture, dirt, and debris from entering and damaging internal electronics.

Keypads are often the front-line interface on a device. Every time someone presses a button, there’s a chance for contaminants to sneak in. This is especially risky in medical tools, outdoor gadgets, and factory equipment.

Without proper sealing, liquid spills can short out a circuit board. Dust can block contacts or degrade tactile feel. That’s why achieving IP ratings (like IP65, IP67) is critical. The keypad must seal perfectly, every time.

How Do Silicone Keypads Achieve Waterproofing?

It’s not just about using silicone. It’s how you shape and install it.

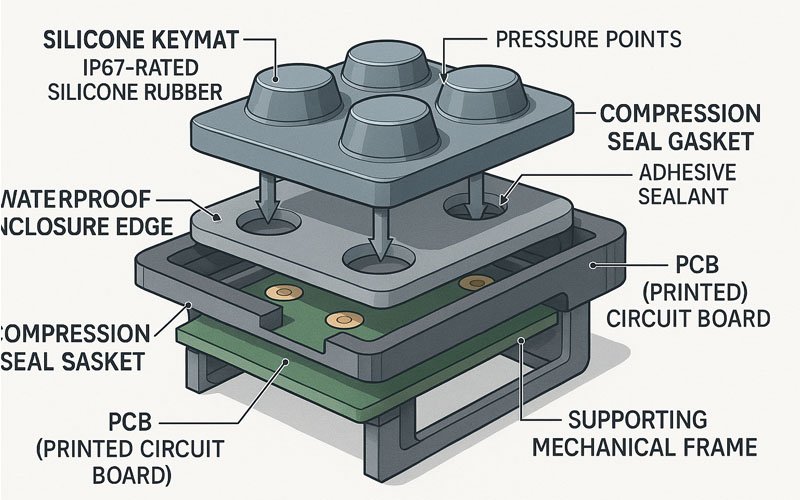

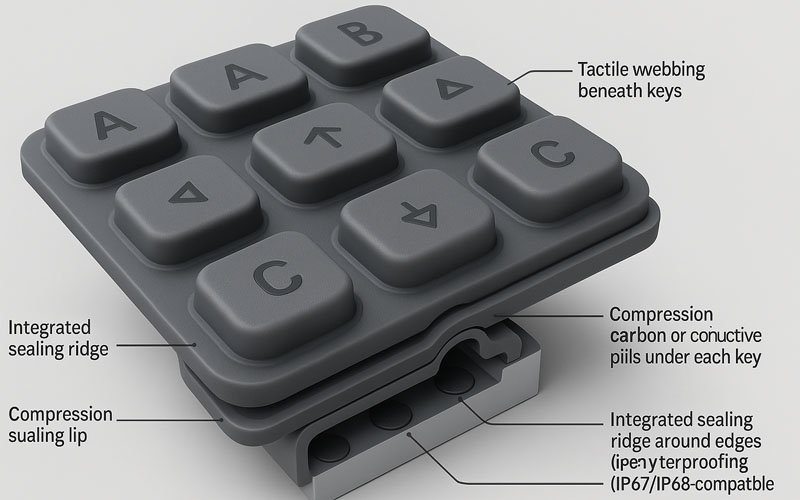

Waterproof silicone keypads use molded sealing features, like perimeter ribs and compression zones, to block liquid entry when pressed against the housing.

Most designs start with a gasket-like rib around the outer edge. This rib compresses tightly against the plastic housing when installed. The silicone must be soft enough to form a tight seal but resilient enough to maintain its shape over years.

Design elements include:

- Peripheral Sealing Ribs: Raised lips that press into grooves on the housing.

- Compression Pads: Areas that deform under pressure to close gaps.

- Over-Molded Membranes: Extra silicone layers over switch areas.

The result? Even if water splashes on the surface or dust blows through vents, the keypad keeps the inner components safe.

What are IP Ratings and Why Do They Matter?

Not all waterproof claims are equal. IP ratings put them to the test.

IP (Ingress Protection) ratings classify the resistance of keypads against solid and liquid intrusion. IP65 to IP67 are common targets for silicone keypads.

Here’s a quick guide:

| IP Rating | Solid Protection | Liquid Protection | Common Use Case |

|---|---|---|---|

| IP54 | Limited dust ingress | Light splashing | Indoor equipment |

| IP65 | Dust-tight | Low-pressure jets | Industrial panels |

| IP67 | Dust-tight | Immersion up to 1 meter | Outdoor or medical devices |

Achieving a rating means lab testing. It also means tight tolerance control in manufacturing. If your product will be used outdoors or near water, IP67 should be your minimum goal.

What Materials and Coatings Are Used?

The base silicone is only the beginning. Add-ons enhance protection.

Silicone keypads often include coatings like PU spray, Parylene, or conformal film to add chemical resistance and improve sealing.

While raw silicone is waterproof, coatings improve its lifespan and resistance to oils, cleaning agents, and UV exposure. Some commonly used finishes:

- PU Coating: Adds scratch resistance.

- Parylene Coating: Adds ultra-thin waterproof protection for electronics.

- Silicone Over-Molding: Adds a second skin to high-contact areas.

Choosing the right combination ensures your keypad not only survives water and dust but also stands up to regular use.

How Does Design Affect Waterproofing?

A good seal depends on good geometry.

Design factors like rib shape, wall thickness, key travel, and housing fit determine how well a silicone keypad resists water and dust.

A few millimeters make a big difference. The sealing rib must press evenly against the enclosure. If the pressure is too low, gaps form. If it’s too high, the silicone deforms and wears out.

Key travel also affects sealing. Shorter travel generally allows for tighter seals, but can reduce tactile feedback. Balance is key. Housing tolerances must be tight, often within ±0.1 mm.

I always design with a 20% compression ratio in mind for sealing ribs. That means the rib should compress by one-fifth of its height when assembled. This ensures a lasting seal without fatigue.

What Industries Benefit Most from Sealed Keypads?

Some environments simply demand more protection.

Medical, industrial, marine, and outdoor electronics benefit the most from waterproof and dustproof silicone keypads.

Here’s how different industries apply sealed designs:

| Industry | Application Example | Why Sealing Matters |

|---|---|---|

| Medical | Diagnostic tools, monitors | Infection control, fluid resistance |

| Industrial | Factory control panels | Dust, grease, vibration |

| Marine | Navigation systems, radios | Water, salt, and weather resistance |

| Consumer Outdoor | GPS units, cameras, wearables | Sweat, rain, mud, and drops |

In my experience, one of the trickiest but most rewarding projects was designing a keypad for a marine radio. We had to balance IP67 waterproofing, UV resistance, and glove usability. With the right geometry and coatings, we pulled it off.

Conclusion

Silicone keypads stay waterproof and dustproof through smart design, right materials, and precise sealing geometry. The details protect your product.