Ever tried using a tiny mat in a massive workspace? It’s like using a post-it note as a doormat. In industrial and commercial settings, small mats just won’t cut it. You need coverage, safety, and durability—on a much larger scale.

Large format silicone mats offer wide-area protection against heat, chemicals, and mechanical wear. Designed for factory floors, large workbenches, assembly lines, or commercial kitchens, these mats deliver the same performance as smaller ones—but on an industrial level. They’re durable, customizable, easy to clean, and built for tough environments.

So, how do they work, where are they used, and why should your customers switch to silicone giants? Let’s explore.

What Exactly Are Large Format Silicone Mats?

Large format silicone mats are oversized silicone sheets designed to protect expansive surfaces in commercial and industrial settings. Think worktables in electronics factories, large baking racks in food production, or floors under high-heat equipment.

Typical sizes range from:

- 50 cm x 75 cm

- 100 cm x 200 cm

- Custom formats up to several meters long

We can manufacture seamless large mats or modular mats with interlocking designs—depending on your project requirements.

Where Are Large Silicone Mats Commonly Used?

Here’s a quick look at who’s using them—and why:

- Electronics Factories: To protect anti-static workstations and resist solder heat and chemical spills

- Commercial Kitchens & Bakeries: For rolling dough, baking in large batches, or protecting stainless steel counters

- Laboratories: As chemical-resistant covers for wide lab benches

- Workshops & Garages: For tool-drop protection and oil resistance

- Textile & Printing Industries: As base layers for heat presses, screen printing, or dyeing tables

If your customer is working big, they need a mat that’s built big too.

Key Features That Make Oversized Silicone Mats Indispensable

Large mats aren’t just about size—they pack in high performance as well:

- High Heat Resistance: Up to 230°C (and 300°C for high-temp formulations)

- Non-Stick & Easy Clean: Repels adhesives, oils, food, and chemicals

- Slip Resistance: Stable grip on most surfaces, improving safety

- Chemical Resistance: Withstands acids, solvents, and greases

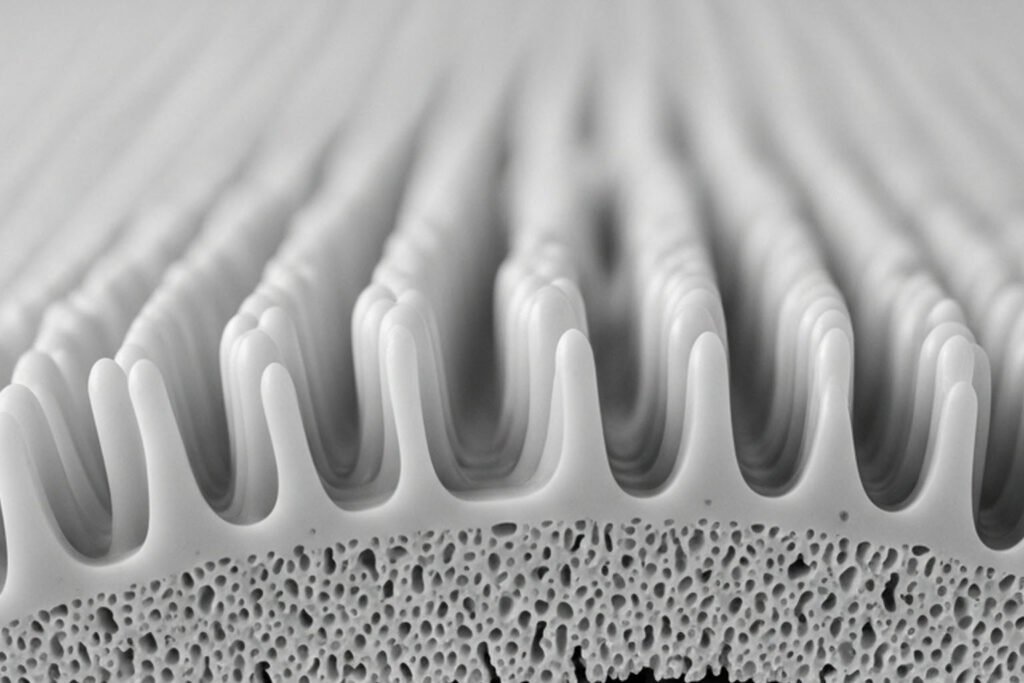

- Cushioning & Shock Absorption: Protects delicate components from drops or scratches

Whether you’re protecting surfaces or creating safe work zones, these mats check all the boxes.

How We Manufacture Large Format Silicone Mats at Ruiyang

Most suppliers struggle with large molds or material consistency. That’s where we shine.

Here’s how we handle large-format silicone with precision:

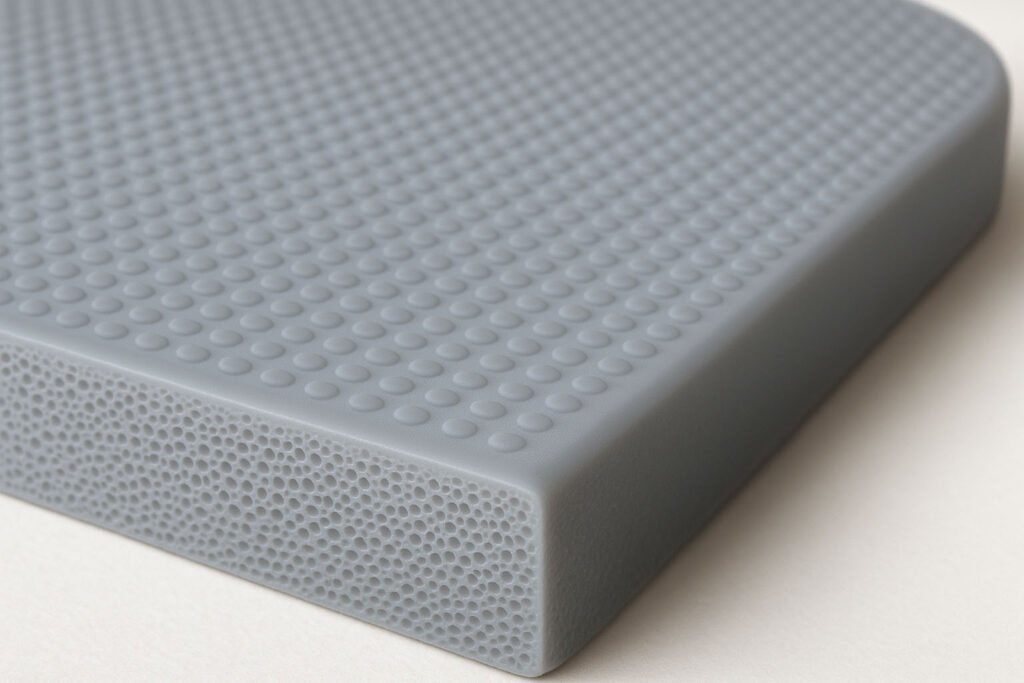

- Material Preparation: Platinum-cured, high-strength silicone is selected based on usage (food-grade, industrial-grade, anti-static, etc.)

- Molding Process:

- For sizes under 100 cm, we use single large molds.

- For bigger formats, we use compression molding in sections, then bond with seamless high-temperature fusing.

- Extrusion + Lamination: For continuous roll formats (used on conveyor belts or printing lines).

- Surface Customization: Smooth or textured, anti-slip patterns, or custom embossing.

- Branding & Edging: Embossed logo, color-coded edges, or hole-punched corners for mounting.

- Quality Control: Full inspection for surface uniformity, flatness, heat resistance, and bonding strength.

Can These Mats Be Customized? Absolutely.

Customization is what makes Ruiyang the go-to B2B partner. For large format silicone mats, we offer:

- Custom Dimensions: Up to several meters wide/long.

- Thickness Options: From 1 mm up to 10 mm.

- Color Matching: Bright colors for visibility or matte tones for labs.

- Logo Placement: Discreet or bold—embossed, debossed, or printed.

- Mounting Features: Grommet holes, adhesive backing, or magnetic strips for metal surfaces.

Need a mat for your 3-meter baking conveyor? Done. Want custom graphics on a 2×1 meter lab surface? No problem.

What Are the Benefits Over Other Large Surface Protectors?

Let’s compare silicone mats to other common large-surface options:

| Material | Heat Resistance | Reusability | Chemical Resistance | Flexibility | Cleanability |

|---|---|---|---|---|---|

| Vinyl Sheets | Low | Low | Moderate | Moderate | Difficult |

| Rubber Mats | Moderate | Moderate | Moderate | Low | Absorbs oils |

| Metal Trays | High | High | High | None | Heavy, hard to clean |

| Silicone Mats | Very High | Very High | Very High | Flexible | Easy |

How Do We Package and Ship Large Format Mats?

Oversized mats require special care in packaging and delivery. At Ruiyang:

- We roll thinner mats with protective layers to avoid creases.

- Flat-pack thicker or modular mats with reinforced corners.

- Palletized shipping for heavy-duty orders ensures mats arrive clean, flat, and undamaged.

For bulk buyers, this means fewer complaints, smoother operations, and better customer retention.

FAQs About Large Format Silicone Mats

Q: What’s the maximum size you can produce in one piece?

A: Up to 1000 mm x 2000 mm in a single mold. Larger sizes can be fused seamlessly.

Q: Can you produce food-grade large mats?

A: Yes—FDA and LFGB certified options are available.

Q: Do you offer anti-static large mats for electronics use?

A: Absolutely. ESD-safe silicone formulas are available upon request.

Q: What’s the lead time for custom oversized orders?

A: Typically 15–25 days, depending on tooling and size.

Q: What’s the MOQ for large format mats?

A: Usually 300–500 pieces depending on complexity and dimensions.

Conclusion

Large format silicone mats are the unsung heroes of industrial and commercial spaces—quietly protecting workstations, improving safety, and extending equipment lifespan. They offer high heat resistance, chemical protection, and unbeatable durability at scale.

At Ruiyang Silicone, we make big solutions easy. From food-grade to factory-grade, from custom sizing to branded finishes—we handle large like it’s our comfort zone.

Let’s talk about your next large-scale silicone mat project—because big problems need big solutions.