Cutting or bonding high-temp silicone isn’t hard—if you understand the right tools, techniques, and mistakes to avoid.

High-temp silicone sheets can withstand up to 230°C and require precise cutting, bonding, and handling techniques to maintain performance during fabrication.

I first used high-temp silicone in an oven gasket project. At the time, I underestimated how different it was from standard silicone. Tools dulled quickly, adhesive failed, and thermal expansion caused poor sealing. Since then, I’ve developed a step-by-step process that works every time.

What Makes High-Temp Silicone Different from Standard Silicone?

It’s not just about heat—it’s about structure, stability, and longevity.

High-temp silicone is formulated with enhanced polymers and additives that allow it to resist temperatures up to 230–300°C without breaking down or deforming.

These sheets are typically:

- Platinum-cured or specially filled for added thermal resistance

- Rated to 230°C continuous, 300°C intermittent exposure

- More dense and elastically stable than general-purpose silicone

- Available in reinforced versions with fiberglass or mesh cores

Here’s a performance comparison:

| Property | Standard Silicone | High-Temp Silicone |

|---|---|---|

| Max Temp (Continuous) | ~200°C | 230–300°C |

| Thermal Aging Resistance | Moderate | Excellent |

| Mechanical Stability | Good | Excellent |

| Common Use | Seals, pads | Oven, engine, furnace parts |

I recommend confirming the exact temperature resistance based on curing type and additives. Some suppliers claim “high temp” but only test at 200°C.

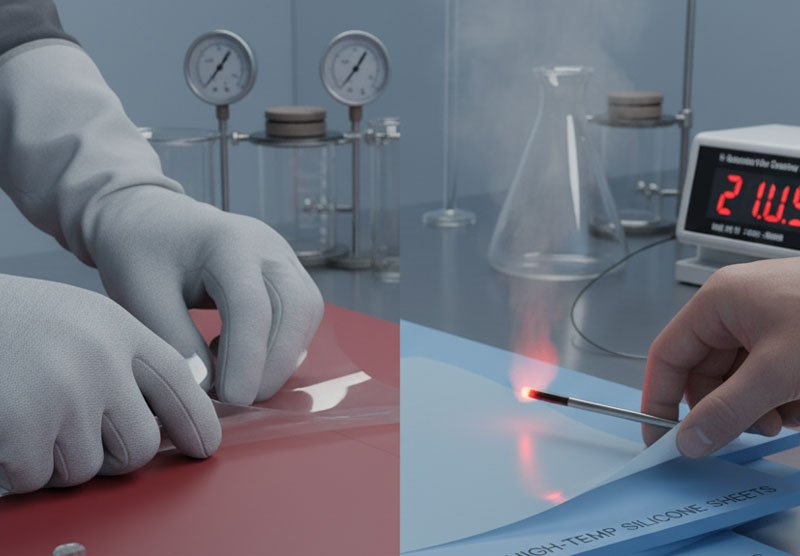

What Are the Best Tools to Cut High-Temp Silicone Sheets?

I once used standard scissors and ended up with ragged, stretched edges—not ideal.

Use sharp blades, rotary cutters, die tools, or waterjet machines to cut high-temp silicone accurately without fraying or distortion.

Depending on the sheet thickness and cut complexity:

- Manual cuts (1–3mm): Use snap-off utility knives or rotary blades

- Die cutting (flat gaskets): Steel-rule dies work well for production runs

- CNC knife cutting: Great for detailed or custom profiles

- Waterjet cutting: Ideal for reinforced silicone or complex shapes

Tips:

- Use a cutting mat to support flexible sheets

- Apply minimal tension to avoid distortion

- Replace blades frequently to avoid drag or burrs

For one client’s heat exchanger gasket, I used 3mm fiberglass-reinforced silicone. Only a waterjet provided the clean edge needed without delaminating the sheet.

How Can You Bond High-Temp Silicone to Other Surfaces?

Bonding is the tricky part. Most adhesives fail above 150°C.

To bond high-temp silicone, use silicone-based adhesives, RTVs rated for 230°C+, or mechanical fastening methods for extreme temperatures.

Best options:

- High-temp RTV silicone adhesive (rated 230°C–315°C)

- Silicone pressure-sensitive adhesive (PSA) with a high-temp liner

- Mechanical fasteners (bolts, rivets) for oven doors or enclosures

- Plasma treatment + adhesive for permanent bond

Adhesive comparison:

| Adhesive Type | Max Temp | Cure Time | Bond Strength |

|---|---|---|---|

| RTV Silicone (Red) | 300°C | 24 hrs | High |

| PSA (High-Temp) | 200°C | Instant | Moderate |

| Epoxy (High-Temp) | 150–180°C | 2–4 hrs | Weak (fails at temp) |

When bonding to metal (e.g., stainless steel oven door), I roughen the surface with 320 grit, clean it with IPA, then apply high-temp RTV. Let it cure at room temp, or heat-cure if needed.

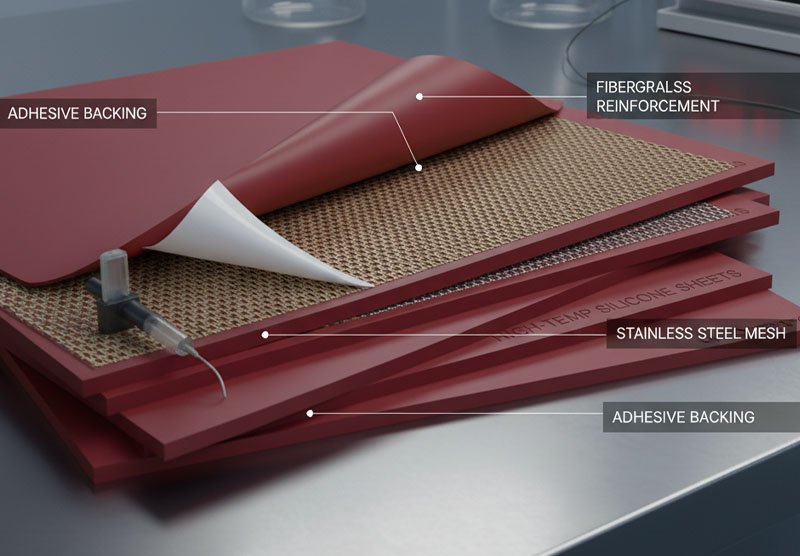

Can High-Temp Silicone Be Reinforced or Laminated?

For tougher jobs like industrial sealing, plain silicone often isn’t enough.

Yes, high-temp silicone sheets can be reinforced with fiberglass, stainless mesh, or laminated with adhesive backings to enhance strength and usability.

Common reinforcement options:

- Fiberglass fabric: Improves tear resistance and dimensional stability

- Wire mesh: Used in flexible heaters or EMI shielding

- Dual-layer laminates: Silicone + PTFE or silicone + PSA

Applications:

| Reinforcement | Benefit | Use Case |

|---|---|---|

| Fiberglass | Tear resistance, rigidity | Oven gaskets, heat press pads |

| PSA Adhesive Backing | Easy install | HVAC seals, thermal pads |

| Wire Mesh | Conductivity, shape retention | Heating mats, engine covers |

I fabricated a heat-resistant flap for an industrial furnace door using 4mm fiberglass-reinforced silicone with riveted corners. It’s been operating for over 2 years without replacement.

What Are Common Fabrication Mistakes to Avoid?

The wrong blade or adhesive can ruin a whole batch.

Avoid common mistakes like using incorrect adhesives, overheating during bonding, storing in poor conditions, or folding reinforced sheets.

Watch out for:

- ❌ Low-temp adhesives: They will delaminate or crack

- ❌ Dull blades: Cause tearing or edge deformation

- ❌ Improper curing: Skipping adhesive cure time leads to weak bonds

- ❌ Overstretching: Warps the cut profile

- ❌ Folding fiberglass-reinforced sheets: Causes internal delamination

Here’s what I always check before final fabrication:

- ✅ Confirm sheet thickness and hardness

- ✅ Use the right cutting tool for the job

- ✅ Verify adhesive temperature rating

- ✅ Clean bonding surfaces thoroughly

- ✅ Label all parts for traceability

A customer once folded a reinforced roll during shipping. The crease damaged the internal fiberglass layer, and the entire batch was rejected after just one test.

Where Can I Source Reliable High-Temp Silicone Sheets?

Not all “high-temp” silicone is tested under real use conditions.

Choose suppliers who offer certified temperature ratings, test data, customization, and fabrication support.

I look for:

- ✅ Proven continuous and peak temperature ratings

- ✅ UL 94 V-0, FDA, or industrial compliance where needed

- ✅ Options for fiberglass reinforcement, PSA, or custom cutting

- ✅ Transparent test data for aging, shrinkage, and adhesion

- ✅ Local or fast-turnaround support for prototypes

Ruiyang produce high-temp silicone sheets rated for continuous use at 230°C+ in standard and reinforced versions. We also offer:

- Custom-cut shapes

- Adhesive laminations

- Die-cut or waterjet services

- Support for oven, furnace, and industrial sealing projects

We’ve supported clients in kitchenware, industrial HVAC, and automotive industries with solutions that survive both heat and pressure.

Conclusion

High-temp silicone sheets require careful cutting, bonding, and reinforcement to handle extreme environments—but when done right, they outperform any other flexible material.