Sustainability isn’t just about the final product—it starts on the factory floor.

Eco-friendly silicone manufacturing involves energy-efficient processes, reduced emissions, waste recycling, and responsible material sourcing to minimize environmental impact while maintaining product quality.

When people think of silicone, they often think of its durability and safety. But fewer people consider how it’s made. At RuiYang, we believe that sustainability starts long before a product reaches the shelf. Here’s how eco-friendly silicone manufacturing is done—and why it matters.

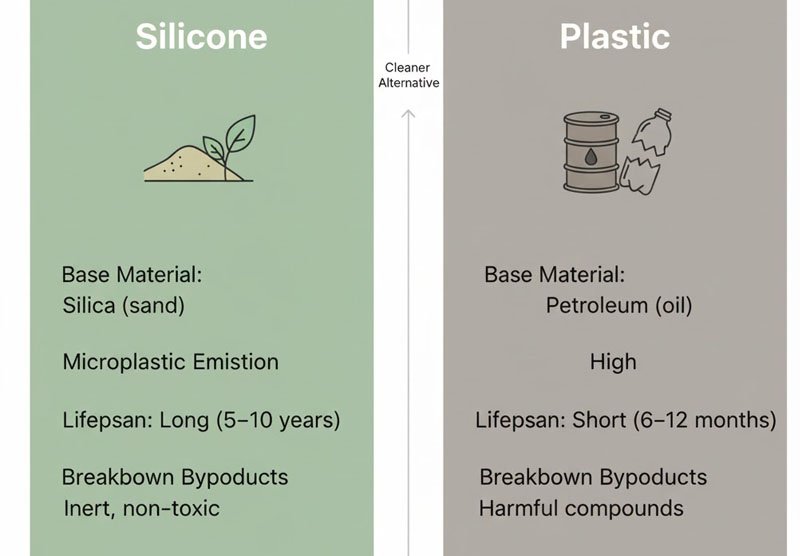

What makes silicone more eco-friendly than plastic?

Material choice influences both product use and production impact.

Silicone lasts longer, breaks down into safer byproducts, and doesn’t generate microplastics—making it a cleaner alternative to petroleum-based plastic.

A Cleaner Material from the Start

Silicone is made from silica, a natural element found in sand. Unlike plastic, which is derived from crude oil and mixed with chemical additives, silicone is chemically stable and doesn’t degrade into harmful particles.

Here’s a quick comparison:

| Feature | Silicone | Plastic |

|---|---|---|

| Base Material | Silica (sand) | Petroleum (oil) |

| Microplastic Emission | None | High |

| Lifespan | Long (5–10 years) | Short (6–12 months) |

| Breakdown Byproducts | Inert, non-toxic | Harmful compounds |

While silicone isn’t biodegradable, its stability and durability make it the more sustainable option long-term—especially when manufactured responsibly.

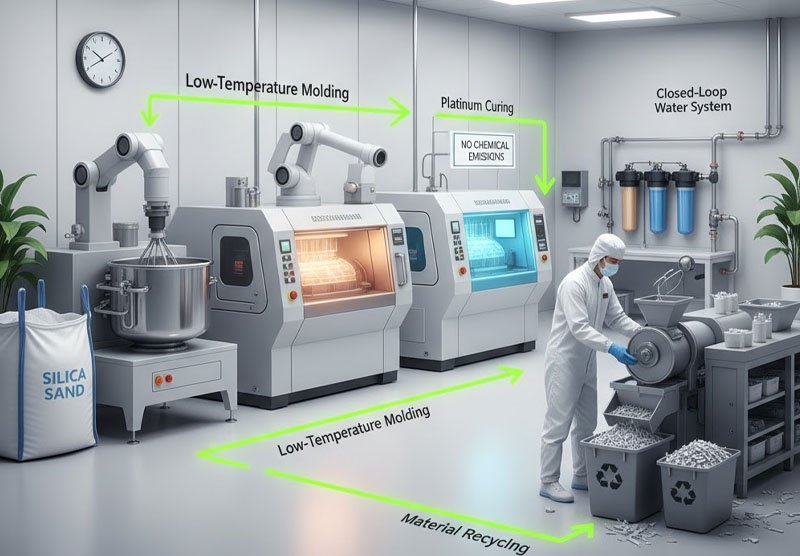

How is silicone manufactured in an eco-friendly way?

Traditional manufacturing processes can use excess energy and produce industrial waste—but that’s changing.

Eco-friendly silicone manufacturing uses closed-loop systems, clean curing processes, and efficient molding techniques to reduce energy and emissions.

Behind the Scenes at the Factory

We’ve optimized our production lines to reduce waste and energy use. Here’s what makes our silicone manufacturing greener:

- Platinum-cured silicone: Uses a cleaner curing agent, eliminating byproducts like peroxide residues.

- Low-temperature molding: Reduces energy consumption during shaping and curing.

- Closed-loop water systems: Recycle water during cooling and cleaning.

- Material recycling: Collect silicone scraps and reintegrate them into new molds.

| Manufacturing Practice | Environmental Benefit |

|---|---|

| Clean curing (platinum) | No chemical emissions |

| Energy-efficient molding | Lower power usage |

| In-house scrap reuse | Reduced raw material waste |

| Water recycling systems | Less water consumption |

We’ve seen a 20–30% drop in factory waste since switching to these processes—and we’re still improving.

What role does material sourcing play in sustainability?

Even the greenest factory can’t fix dirty raw materials.

Responsible silicone manufacturing starts with high-quality, food-grade silicone sourced from certified suppliers with sustainable extraction and processing practices.

Start Clean, Stay Clean

Silicone is derived from quartz, which requires energy-intensive refining. That’s why it’s important to work with ethical suppliers who minimize environmental harm during extraction and processing.

At RuiYang, we only work with suppliers who:

- Use ISO-certified environmental practices

- Limit emissions during quartz refinement

- Maintain transparency on material content

- Follow REACH and RoHS safety standards

By sourcing only food- and medical-grade silicone, we reduce the risk of harmful substances entering our supply chain—ensuring the final product is safe for babies, kitchens, and the environment.

Can waste from silicone production be recycled?

Silicone doesn’t melt like plastic, but that doesn’t mean it can’t be reused.

Scraps from silicone manufacturing can be collected, reprocessed, and molded into new products—reducing raw material usage and waste.

The Circular Silicone Loop

In traditional factories, silicone off-cuts and mis-molded parts are thrown away. We do things differently. Our production system allows us to:

- Sort and grind leftover silicone

- Blend scrap with fresh material for non-critical parts

- Create new molds from recycled silicone where safety standards allow

| Type of Waste | Recycling Method | Final Use |

|---|---|---|

| Trimmed edges | Re-melt and mix | Non-contact products |

| Mis-molded items | Regrind and reform | Toy bases, mat liners |

| Packaging waste | Sorted for external recycling | General waste management |

While food-grade items must still use virgin material, repurposing internal waste reduces landfill load and saves costs—without sacrificing quality.

How do eco-friendly factories reduce emissions?

Power, heat, and logistics contribute to manufacturing’s carbon footprint.

Green silicone factories invest in energy-efficient machines, switch to renewable energy sources, and improve logistics to cut emissions at every step.

Making Every Watt Count

Our team tracks factory emissions monthly. By upgrading our machines and improving layout flow, we’ve lowered energy usage by 15% in the last year alone.

Key improvements:

- LED lighting & smart energy systems

- Solar panel integration

- Consolidated machine scheduling to reduce idle power

- In-house packaging to cut shipping emissions

We’re also working with local transport partners to streamline logistics with fewer, more efficient shipments.

These changes not only reduce carbon emissions—they lower operating costs and increase production consistency.

What are the long-term benefits of eco-friendly silicone manufacturing?

Going green isn’t a short-term PR move—it’s a long-term strategy.

Eco-friendly silicone manufacturing protects the environment, builds customer trust, and reduces long-term costs through waste reduction and energy savings.

Building a Sustainable Brand

I’ve worked with baby brands, kitchenware companies, and industrial suppliers. What they all want now is the same: reliable, safe, and sustainable products.

Eco-friendly silicone manufacturing offers:

- Lower environmental impact

- Stronger customer loyalty

- Compliance with global regulations

- Better working environments

- Future-proof production systems

This approach has helped us attract long-term partners who share our vision. It also gives us a competitive edge as sustainability becomes a purchasing priority worldwide.

Conclusion

Eco-friendly silicone manufacturing isn’t just possible—it’s essential. From clean materials to efficient processes, it’s the smarter way to produce safe, sustainable products for the future.