Picture this: You’re strolling down the street, enjoying the warm sunshine, when suddenly, you spot a building with a beautifully designed glass facade. The first thing that catches your eye is the strikingly clear and seamless silicone joint that holds the glass panels together. Ever wondered what material is responsible for that flawless finish? Enter the world of silicone rubber sheets – the unsung heroes of modern construction and manufacturing.

A Material with Many Faces

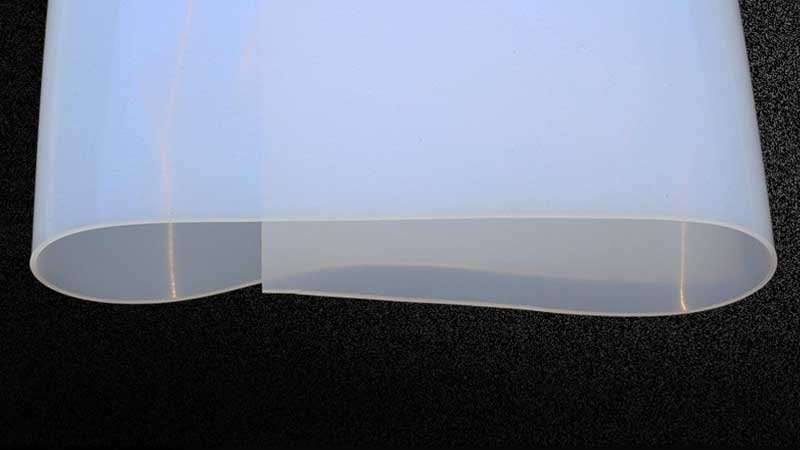

Silicone rubber sheets are like chameleons in the world of materials. They possess a remarkable ability to adapt to various environments and applications, making them a go-to choice in numerous industries. From aerospace to automotive, from food and beverage to electronics, silicone rubber sheets have found their way into a wide range of products and processes.

But what makes silicone rubber sheets stand out? Let’s take a closer look.

Properties that Set Silicone Rubber Sheets Apart

Silicone rubber sheets possess a unique combination of properties that make them highly sought after for various applications. Let’s delve into some of the most remarkable characteristics of this versatile material:

1. Temperature Resistance: Taming the Heat

Silicone rubber sheets exhibit excellent resistance to extreme temperatures, both high and low. They can withstand scorching heat without losing their structural integrity or degrading their physical properties. This remarkable temperature resistance allows silicone rubber sheets to thrive in environments where other materials would fail, making them an ideal choice for applications ranging from aerospace to food processing.

2. Flexibility and Elasticity: Adapting to Any Shape

One of the standout qualities of silicone rubber sheets is their remarkable flexibility and elasticity. They can be easily molded into various shapes and contours, making them a favorite material for gaskets, seals, and insulation components. This flexibility ensures a tight seal even in irregular or uneven surfaces, providing efficient protection against leaks or environmental factors.

3. Chemical Resistance: Standing Strong Against Corrosion

Silicone rubber sheets demonstrate exceptional resistance to a wide array of chemicals, including acids, bases, solvents, and oils. This chemical resistance makes them ideal for applications that involve exposure to corrosive substances. From chemical processing plants to medical devices, silicone rubber sheets provide reliable protection against chemical corrosion, ensuring longevity and performance.

4. Electrical Insulation: A Shield against Electrical Hazards

Silicone rubber sheets possess excellent electrical insulation properties, making them an excellent choice for electrical applications. They can insulate against high voltages, preventing electrical arcing and ensuring safety. This property makes them a vital component in industries such as electronics, power generation, and electrical equipment manufacturing.

Manufacturing Process of Silicone Rubber Sheets

The manufacturing of silicone rubber sheets involves several steps to ensure the desired quality and properties are achieved. Let’s take a closer look at the typical manufacturing process:

- Raw Material Preparation: The silicone rubber compound is prepared by mixing the silicone polymer with additives such as fillers, pigments, and cross-linking agents. This process allows the customization of the sheet’s properties according to specific requirements.

- Mixing and Dispersion: The prepared silicone compound is mixed in specialized equipment to ensure uniform dispersion of additives. This step plays a crucial role in achieving consistent material properties and color distribution.

- Rolling and Calendering: The mixed silicone compound is passed through a series of rollers or a calendering machine. This process shapes the compound into a continuous sheet of the desired thickness.

- Curing and Vulcanization: The formed silicone sheet is then subjected to a curing process, where it is exposed to heat and pressure. This process activates the cross-linking agents in the compound, causing it to undergo vulcanization and gain its final properties.

- Surface Treatment: Depending on the intended application, the silicone rubber sheet may undergo surface treatment processes such as coating, texturing, or adhesive application. These treatments enhance the sheet’s performance and allow for better adhesion or functionality in specific applications.

A Material for Endless Possibilities

Now that we’ve explored the world of silicone rubber sheets and their manufacturing process, it’s time to appreciate their incredible versatility. Let’s take a moment to imagine some real-life applications that showcase the potential of these remarkable sheets:

- Automotive Industry: Silicone rubber sheets find their place under the hood of vehicles, providing durable gaskets and seals that withstand extreme temperatures, oil exposure, and vibration. They also play a vital role in automotive lighting, ensuring that headlights and taillights remain watertight and free from dust.

- Construction and Architecture: From curtain walls to glass facades, silicone rubber sheets are instrumental in creating stunning architectural designs. Their ability to bond glass panels seamlessly not only enhances the visual appeal but also ensures structural integrity and weather resistance.

- Food and Beverage Industry: Silicone rubber sheets are an excellent choice for food-grade applications. They can be used to create flexible molds for chocolate or confectionery production, as well as providing safe and hygienic seals for food processing equipment.

- Electronics and Electrical Engineering: Silicone rubber sheets’ electrical insulation properties make them indispensable in the world of electronics. They are used as insulation covers, gaskets, and seals, protecting sensitive electronic components from environmental factors and ensuring optimal performance.

These are just a few examples of how silicone rubber sheets contribute to our daily lives. Their versatility and durability enable innovation across multiple industries, making them an essential component in countless products and processes.

Frequently Asked Questions (FAQs)

Q: What is the price of food grade silicone sheet?

A: The price of food grade silicone sheets can vary depending on factors such as thickness, size, and quantity. It is best to contact our consult for specific pricing information.

Q: How thick is silicone rubber sheet?

A: Silicone rubber sheets come in various thicknesses, ranging from thin sheets of a few millimeters to thicker sheets measuring several centimeters. The thickness required for a specific application depends on the intended use and the level of durability or insulation needed.

Q: How long do silicone sheets last?

A: The lifespan of silicone sheets depends on various factors, including the quality of the material, the specific application, and the environmental conditions. High-quality silicone sheets can last for years, maintaining their properties and performance throughout their lifespan.

Q: How many times can you use a silicone sheet?

A: The number of times a silicone sheet can be used depends on the specific application, the quality of the sheet, and how well it is maintained. Silicone sheets that are well cared for and used within their recommended parameters can be reused multiple times, providing cost-effective and reliable performance.

Q: How do you join silicone rubber sheets?

A: Silicone rubber sheets can be joined using various methods, depending on the specific application and requirements. Common techniques include adhesive bonding, mechanical fastening, and heat welding. The appropriate joining method will depend on factors such as the desired strength of the joint, the surface characteristics of the sheets, and the environment in which they will be used.

The Journey Continues

As we conclude our exploration of silicone rubber sheets, it’s clear that these remarkable materials have revolutionized the way we construct, manufacture, and innovate. From their outstanding temperature resistance to their flexibility and electrical insulation properties, silicone rubber sheets have proven their worth in diverse applications.

To embark on your own journey with silicone rubber sheets, finding the right supplier is crucial. That’s where RY Silicone comes into play. With commitment to quality, extensive product range, and exceptional customer service, RY Silicone is your trusted partner in the world of silicone rubber sheets.

So, whether you’re a designer creating the next architectural marvel or an engineer pushing the boundaries of technology, remember that silicone rubber sheets are ready to be your reliable ally in turning your ideas into reality.

Experience the possibilities with RY Silicone – your gateway to a world of innovation and endless opportunities. Click here to contact.