Have you ever encountered a manufacturing challenge that traditional methods couldn’t solve efficiently? In the realm of industrial production, particularly in sectors reliant on versatile materials like silicone, the quest for more adaptive and innovative fabrication methods is never-ending. The limited versatility of traditional molding can be a significant hurdle, increasing both costs and production times.

Can 3D printers offer a solution by printing silicone? Yes, they can. Recent advancements in 3D printing technology have enabled the use of silicone as a viable printing material. This capability opens up new avenues for creating more complex and customized silicone components that were previously challenging or even impossible to produce through conventional molding.

The implications of this development are vast and could revolutionize how industries approach silicone-based production.

Why is Silicone a Preferred Material in Manufacturing?

Silicone is renowned for its thermal stability, chemical inertness, and flexibility, making it a favored choice across various industries, including automotive, aerospace, medical, and consumer goods. However, its very versatility can sometimes be a constraint in traditional manufacturing due to the complexities of molding intricate shapes.

What Challenges Do Traditional Silicone Molding Present?

Traditional molding processes for silicone involve time-consuming setups and high costs, especially for custom-designed parts. Each new part design might require a new mold, which is not cost-effective for small batch productions. Moreover, the rigidity of mold designs limits the ability to customize features easily.

How Does 3D Printing Overcome These Challenges?

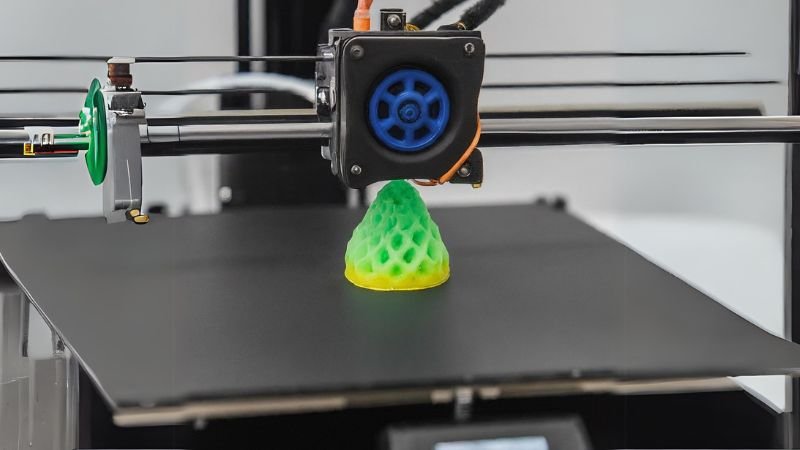

3D printing, or additive manufacturing, builds objects layer by layer, based on digital models, allowing for high levels of detail and design complexity without the need for multiple molds. This method significantly reduces the lead time and cost, particularly beneficial for custom and small-batch silicone products. Additionally, 3D printing offers the potential to adjust material density and texture through print settings, providing even greater customization.

What Are the Current Capabilities of Silicone 3D Printing?

Technological breakthroughs have led to the development of specialized 3D printers that can handle silicone. These printers utilize a process similar to the direct ink writing (DIW) method, where silicone is extruded through a nozzle, cured rapidly via ultraviolet light, and layered precisely to form durable, functional objects. Researchers and companies continue to refine this technology, enhancing its reliability and the quality of the objects produced.

What Applications Can Benefit From Silicone 3D Printing?

The potential applications for 3D-printed silicone are broad. In the medical field, for example, providers can use silicone 3D printing to create custom prosthetics or organ models for surgical preparation. In the consumer sector, manufacturers can develop bespoke products tailored to individual needs, such as ergonomic grips, seals, gaskets, and even footwear soles.

What Future Developments Are Expected in Silicone 3D Printing?

The future of silicone 3D printing looks promising, with ongoing research aimed at improving the material formulations and printing processes. Advances may soon allow even greater control over the mechanical properties of silicone, broadening the scope of applications to more demanding environments like high-temperature or corrosive contexts.

Conclusion

The ability of 3D printers to handle silicone efficiently marks a significant leap forward in manufacturing flexibility and innovation, promising to reshape how industries design and produce silicone-based products.

Related posts: