Custom keypads aren’t just about shape and size—they’re about function, user experience, and branding. The right design makes all the difference.

Custom silicone keypad design involves selecting layout, material, tactile feel, and surface finish to match product requirements and user interaction goals.

I’ve worked with many clients across industries—from medical devices to consumer electronics—and they all face the same question: how do we design a keypad that’s functional, reliable, and easy to use? Let me show you what’s involved.

What are the key factors in keypad layout design?

The layout affects how users interact with your device. Spacing, size, and feedback must be intentional.

Keypad layout defines button size, spacing, position, and overall shape. A well-designed layout improves usability and minimizes input errors.

Layout is usually the first discussion I have with clients. For example, if it’s a medical device, spacing must allow for gloved hands. For a handheld remote, the thumb zone matters most. The number and size of keys should match the user’s task without overcrowding.

We use ergonomic studies and user testing to plan button placement. Button shapes (round, oval, rectangular) are also tailored based on how frequently they’re pressed and what function they serve.

Layout Tips

| Aspect | Impact on Usability |

|---|---|

| Key spacing | Prevents accidental presses |

| Button shape | Guides finger placement |

| Key grouping | Speeds up navigation |

| Orientation cues | Improves tactile recognition |

A clean layout ensures the keypad looks and feels right in users’ hands.

How do you choose the right material and hardness?

Material defines how the keypad feels, reacts to pressure, and lasts over time.

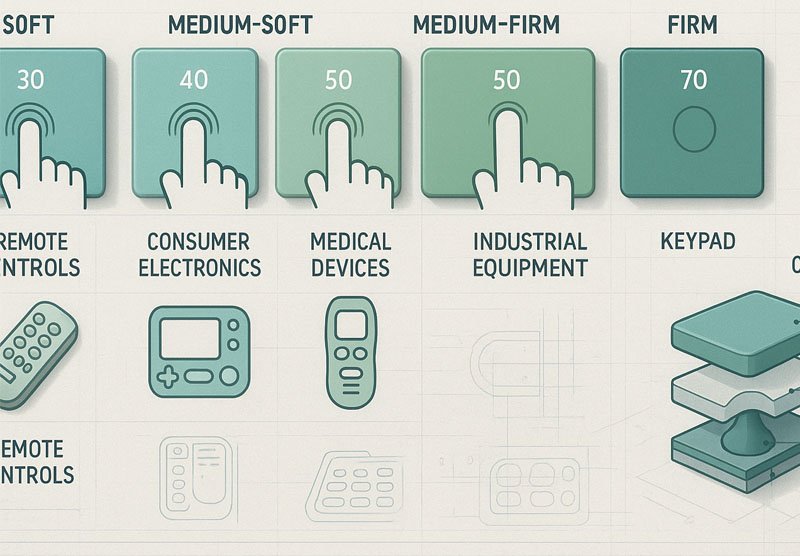

Material choice affects flexibility, temperature resistance, and tactile response. Shore A hardness typically ranges from 30 to 70 depending on the application.

We typically use VMQ silicone because it works well in both indoor and outdoor settings. But not all silicone is the same. For softer touch, we recommend Shore A 30-40. For firmer, more resistant feedback, Shore A 60-70 is better.

In baby products, for example, safety and softness are top priorities. For industrial devices, resistance to oil, heat, or chemicals becomes more important.

We also add FDA or medical-grade certifications when needed. The silicone’s performance must match the device’s environment.

Silicone Hardness Guide

| Shore A Value | Feel | Common Use Cases |

|---|---|---|

| 30-40 | Soft and flexible | Baby products, soft controls |

| 50-60 | Balanced feel | Consumer electronics, remotes |

| 70+ | Firm and stiff | Industrial, ruggedized devices |

Material affects more than just feel—it impacts lifespan and compliance too.

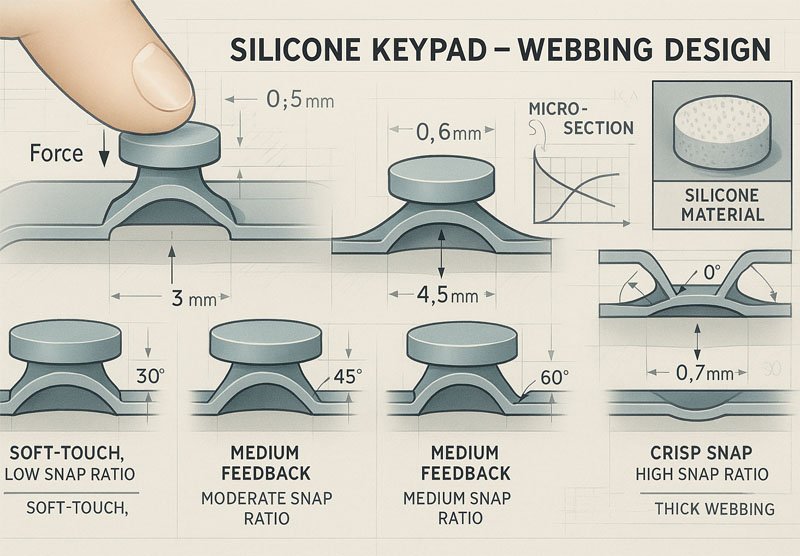

What is webbing and why is it important?

Webbing controls the tactile feedback—the press and return of each button.

Webbing is the thin silicone wall around each button. Its thickness and angle determine tactile force and snap feel.

Every key has a cone-like base underneath. This is the webbing. When pressed, it collapses and then rebounds. Its design affects how much force is needed to press and how quickly it returns.

We use simulation software to test different webbing profiles before mold cutting. A typical tactile force ranges from 100g to 250g. If the force is too low, accidental presses happen. Too high, and it tires the user.

Webbing Parameters

| Feature | Effect |

|---|---|

| Thickness | Controls tactile force |

| Angle | Affects rebound speed |

| Material stiffness | Modifies snap feel |

Getting webbing right is critical. It’s what gives the keypad its “feel.”

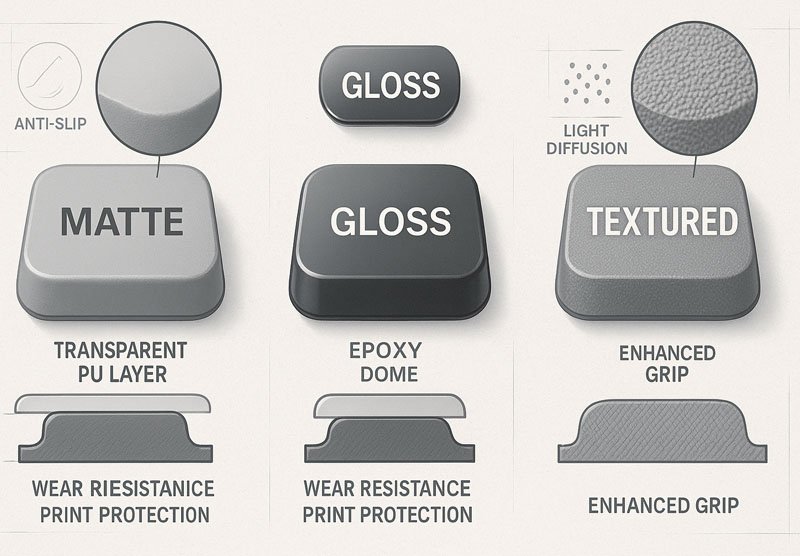

What surface finishes and coatings are available?

Surface finish affects both the look and durability of the keypad.

Surface finish options include matte, gloss, or textured. Protective coatings like PU or epoxy are added for wear resistance, printing protection, and enhanced grip.

Finishing isn’t just about looks—it protects the keypad too. For harsh environments, we apply abrasion-resistant PU coatings. These are ideal for outdoor or industrial use. For medical devices, we go for anti-bacterial and easy-to-clean coatings.

Laser etching is popular for backlit designs. We first spray the keypad with a dark coating, then laser off the letters to allow light through.

We also use silicone spray coatings for matte or rubberized textures. These help reduce fingerprints and improve tactile comfort.

Finish Options

| Finish Type | Benefits |

|---|---|

| PU Coating | Scratch and wear resistance |

| Epoxy Dots | Adds gloss and highlights key areas |

| Matte Texture | Reduces glare and improves grip |

| Laser Etching | Enables backlighting |

The right finish balances form and function.

How do legends and icons stay visible and durable?

Printing techniques determine how long your labeling lasts under use.

Legends can be printed, laser-etched, or molded. For long-term use, laser etching or epoxy-filled molded legends are most durable.

For simple designs, we use pad printing or silk screen. This works well for low-wear areas. But over time, printing can fade. For high-use buttons, laser etching is better. It lasts longer, especially when combined with a top coat.

Molded-in legends—where the text or icon is part of the silicone—are extremely durable. We use different colored silicone layers, and then inject the shape directly.

Legend Techniques

| Method | Durability | Look |

|---|---|---|

| Silk Screen | Medium | Sharp and clear |

| Laser Etching | High | Backlight capable |

| Molded-in Colors | Very High | Seamless design |

We guide clients on which method suits their product best.

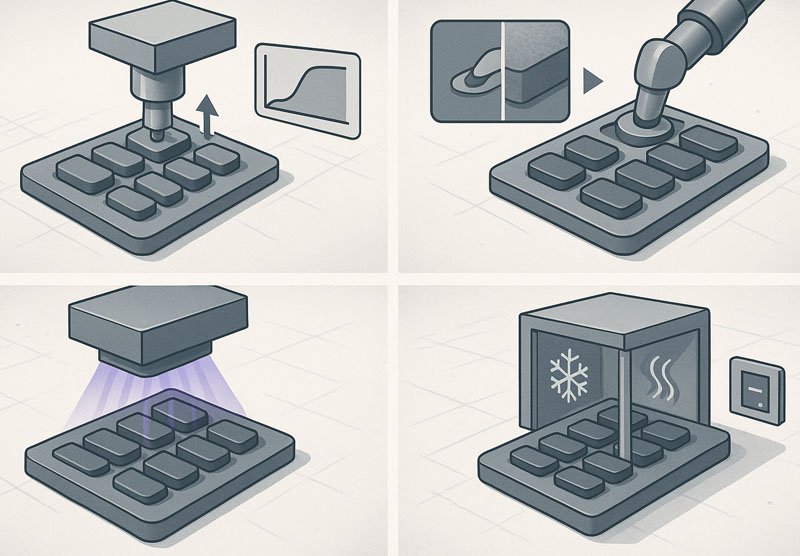

What testing ensures the keypad meets performance standards?

No design is complete without testing. It validates every design choice.

Keypads go through tests for tactile force, wear resistance, UV exposure, and environmental durability. Each test confirms performance in real-world conditions.

We perform tactile force testing using force-displacement machines. This ensures every button meets target specs. We also run cycle life tests—each button must withstand 500,000 to 1 million presses without failure.

Other tests include:

- UV aging for outdoor products

- Salt spray for marine or humid environments

- Drop and impact resistance

- Heat and cold cycles from -40°C to 200°C

All this ensures the keypad not only looks right but works right under any condition.

Testing Overview

| Test Type | Purpose |

|---|---|

| Tactile Force | Ensures press feedback consistency |

| Wear Resistance | Checks coating and legend durability |

| UV/Temp Cycling | Validates outdoor use durability |

| Life Cycle Test | Confirms long-term button reliability |

Without testing, design is just a guess. With it, you get guaranteed performance.

Conclusion

Custom silicone keypad design requires clear goals, thoughtful decisions, and precise execution. Every step—from layout to coating—affects the final product’s performance and user satisfaction.