Pressing a button should feel right. If it doesn’t, users notice—and they won’t like it.

Tactile feedback and actuation force in silicone keypads define how responsive and comfortable a key feels when pressed. They influence usability, satisfaction, and product performance.

Getting this balance right is more than just mechanical. It’s about matching the feel to your user’s needs. I’ve designed for toys, industrial gear, and medical tools—each one demanded a unique tactile profile.

What is Tactile Feedback in Silicone Keypads?

Tactile feedback is the language of buttons. It tells the user, “Your input was received.”

Tactile feedback refers to the physical sensation a user feels when pressing a button, typically a click or resistance that signals successful actuation.

In silicone keypads, tactile feedback usually comes from a dome structure under each key. When pressed, the dome collapses and then springs back into shape, creating a crisp “snap” sensation. This feedback confirms the action.

Designers can tune the feel by changing:

- Dome shape (flat, round, conical)

- Wall thickness

- Silicone hardness (measured in Shore A)

- Travel distance (how far the button moves)

Getting this wrong can ruin the user experience. Too soft, and it feels mushy. Too stiff, and it becomes tiring to use. I once had to redesign a keypad because factory workers were getting finger fatigue—it all came down to feedback tuning.

What is Actuation Force?

It’s not just how a button feels—it’s how much effort it takes.

Actuation force is the amount of pressure, measured in grams or Newtons, required to press a key until it registers an input.

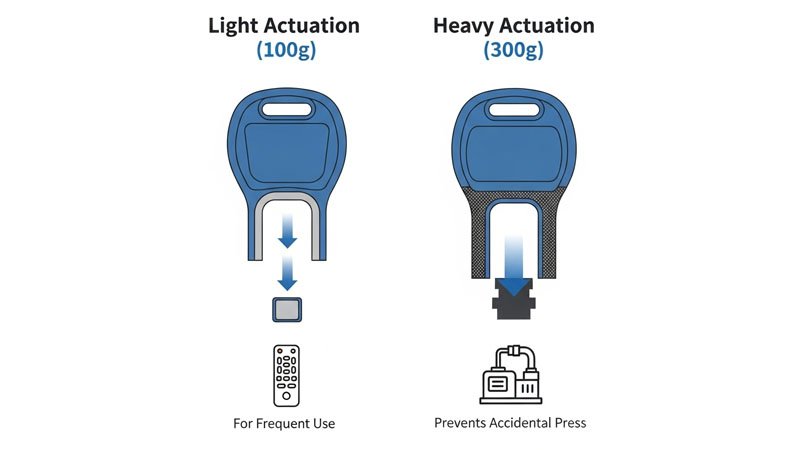

Typical values range from 100g to 300g, depending on application. Lighter forces suit handheld or frequent-use devices. Higher forces are better for rugged tools or preventing accidental presses.

Here’s how force affects use:

| Force Range | User Feel | Common Application |

|---|---|---|

| 80g–120g | Light, responsive | Remote controls, wearables |

| 130g–180g | Balanced, versatile | Consumer electronics |

| 190g–300g | Firm, deliberate | Industrial, outdoor equipment |

When I designed a medical device keypad, we settled at 150g for balance—easy to press with gloves, but not so light it triggered accidentally.

How Are Tactile Feedback and Actuation Force Measured?

You can’t design by feel alone. You need data.

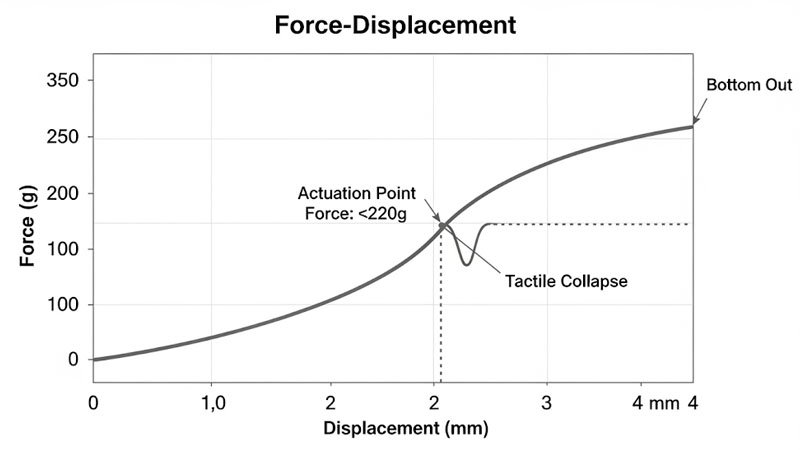

Tactile feedback is measured by force-displacement curves, while actuation force is measured using test jigs and force gauges in controlled environments.

The most common way is using a force tester. This presses a button at a consistent speed and records how much force is needed at each millimeter of travel.

The output is a curve that shows:

- Peak Force: The max force before collapse

- Tactile Ratio: Drop from peak to bottom-out force (higher is snappier)

- Return Force: How strongly the dome returns to shape

For example, a dome with a 200g peak force and 60% tactile ratio will feel more clicky than one with a 40% ratio. These numbers help us match design goals with real-world sensations.

How Do Material and Design Affect Feedback?

Feedback isn’t just shape—it’s chemistry too.

Material hardness, wall thickness, dome height, and internal geometry all control how tactile a silicone keypad feels and how much force it needs.

Silicone hardness is key. Measured in Shore A, softer silicone (30–40A) provides a smoother, quieter press. Harder silicone (50–70A) delivers a crisper snap. But harder isn’t always better—it can wear out faster under stress.

Other design tweaks:

- Thicker walls = higher force, firmer feel

- Taller domes = longer travel, more click

- Vented domes = smoother collapse

Here’s a breakdown:

| Factor | Effect on Feel |

|---|---|

| Shore A Hardness | Higher = stiffer press |

| Dome Height | Higher = more travel/click |

| Wall Thickness | Thicker = more force needed |

| Vent Hole | Present = softer response |

Balancing these factors is both art and science. I’ve spent hours with engineers tweaking dome designs by fractions of a millimeter to hit the right force curve.

What Applications Need High vs Low Actuation Force?

Not all users press buttons the same way.

High actuation force is best for rugged, outdoor, or industrial use. Low actuation force suits consumer electronics, toys, or accessibility-focused designs.

Here’s what I recommend based on real-world needs:

| Product Type | Preferred Force | Reason |

|---|---|---|

| Medical Touch Panels | 130–150g | Gloves, responsive but easy on hands |

| Outdoor Controllers | 200–250g | Prevent accidental press, resist weather |

| Consumer Electronics | 100–130g | Comfortable, fast use |

| Children’s Devices | 80–100g | Soft, safe for small fingers |

| Industrial Machinery | 250–300g | Strong press for durability and accuracy |

One project involved an automotive dashboard button. We tested different forces in a cold chamber to mimic winter driving. The 180g dome performed best with gloves, even when stiffened by cold.

How to Choose the Right Settings for Your Keypad?

Start with the user. Always.

To choose the right tactile feedback and actuation force, consider your end user’s habits, environmental conditions, and device purpose.

Here’s my checklist:

- Who is the user? Age, strength, environment

- How often will they press the key?

- Will they wear gloves?

- Is precision important?

- Does the product need to feel premium or rugged?

Then I simulate those conditions in prototype testing. One small tweak can change the whole experience. A great keypad feels like it was designed just for you—because it was.

Conclusion

Tactile feedback and actuation force shape every keypad press. Get them right, and your product becomes effortless to use.