Could Adding Silicon Nanoparticles to Silicone Revolutionize Manufacturing Processes?

In this article, we explore silicone nanoparticle-embedded reactive molding, a method that combines nanotechnology with silicone molding techniques to enhance material properties. We will discuss nanoparticles, reactive molding, essential performance tests, applications, and its promising market potential.

What Is Silicone Nanoparticle-Embedded Reactive Molding?

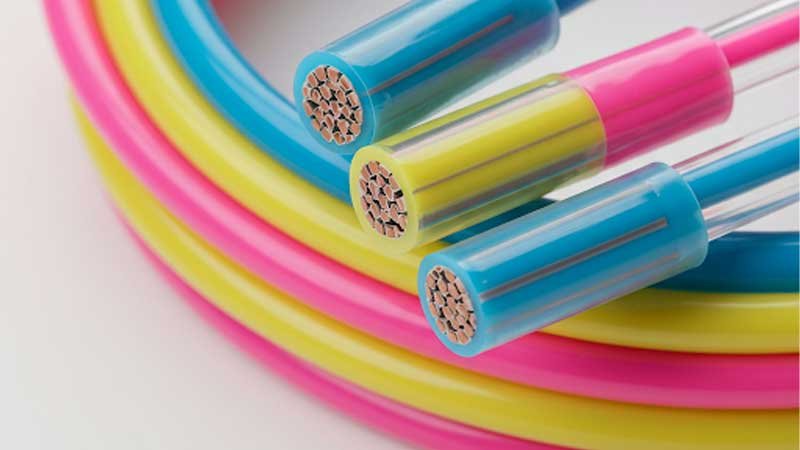

Silicone Nanoparticle-Embedded Reactive Molding is a method for creating specialized silicone products. In this process, nanoparticles of silicon are evenly mixed into the silicone base material. Then, the silicone is molded using a reactive molding process, such as injection molding or compression molding, to solidify and take shape. During this process, the tiny silicon particles are securely embedded within the molded silicone, forming a nanocomposite material. This material may have specific enhanced or functional properties, such as improved thermal conductivity or antimicrobial capabilities, depending on the type of silicon nanoparticles.

What Do You Need to Know About Silicon Nanoparticles?

The Diversity of Silicon Nanoparticle Types

Silicon nanoparticles come in various types. These include pure silicon, silica, and other silicon-based nanoparticles.

For instance, organic-silicon-modified nanoparticles have organic silane coupling agents or other groups attached to their surface. This modification improves their compatibility and dispersion in silicone.

There are also porous silicon nanoparticles with high surface area and tunable pore structures. These are useful for applications like drug delivery and adsorption.

Quantum dots are tiny silicon nanocrystals with unique light-emitting properties. They find applications in optoelectronic devices and biological imaging.

Preparation Methods for Silicon Nanoparticles

Silicon nanoparticles can be made in different ways.

One method is chemical vapor deposition. This process uses silicon precursors like silane, which react in the vapor phase to form nanoparticles.

Another method is the sol-gel process. It involves hydrolyzing and condensing silicon compounds in liquid form to create a gel. After drying and heat treatment, nanoparticles are produced.

Mechanical grinding is also used to break bulk silicon into nanosized particles.

In chemical vapor condensation, silicon sources are heated and evaporated. The vapor then condenses in a low-temperature gas to form nanoparticles.

The preparation method affects the size, shape, purity, and surface properties of nanoparticles. These factors influence how well the nanoparticles disperse in the silicone matrix and the performance of the final composite material.

Surface Modification Strategies for Silicon Nanoparticles

To improve dispersion and compatibility in the silicone matrix, surface modification is often needed.

Silane coupling agents introduce functional groups to the nanoparticle surface, which bond well with the silicone matrix.

Another method is polymer coating. It improves stability and dispersion in solvents or polymer matrices.

Electrostatic stabilization involves adding charged groups to the surface of nanoparticles. This prevents agglomeration by using electrostatic repulsion.

The choice of surface modification depends on the type of silicone matrix, the curing process, and the final application.

What Should You Know About Reactive Molding?

Liquid Silicone Rubber (LSR) Reactive Molding

LSR reactive molding typically uses a two-component system. After components A and B are precisely mixed, they are heated in the mold to form a cross-linked silicone product. The entire injection molding process relies on precise equipment that injects the well-mixed LSR into the preheated mold cavity. The curing process is completed quickly within the mold.

The key advantage of LSR reactive molding is its short molding cycle, high precision, and ease of automation. This ensures stable product quality and is ideal for producing complex and thin-walled shapes. However, its main disadvantages are the high investment cost of equipment and raw material costs.

High Consistency Rubber (HCR) Reactive Molding

Unlike LSR, HCR reactive molding can use either a single-component or two-component system. The molding methods for HCR are more diverse and include compression molding, extrusion molding, and calendering.

Compared to LSR, the advantages of HCR include a wider range of material options, a more mature production process, and lower equipment investment costs. However, the molding cycle for HCR is usually longer, with lower precision and less automation than LSR.

Key Factors Affecting Reactive Molding

Whether using LSR or HCR reactive molding, several critical factors directly influence the final product’s quality and performance.

- Temperature Control: Accurate mold temperature control is essential for curing rate and final performance of silicone.

- Pressure Control: Proper injection or compression pressure helps fill the mold effectively and reduce bubbles.

- Time Control: Curing time must be optimized based on the silicone formula and mold temperature.

- Rheological Properties: The viscosity and flowability of the silicone material directly affect its ability to fill the mold effectively.

What Performance Tests Are Needed for Composite Materials Made by Silicone Nanoparticle-Embedded Reactive Molding?

The composite materials obtained by Silicone Nanoparticle-Embedded Reactive Molding need to undergo comprehensive performance evaluation.

| Test Category | Test Methods and Parameters |

| Microstructural Analysis | SEM, TEM for nanoparticle dispersion and interface in silicone matrix. |

| Mechanical Performance | Tensile strength, elongation, hardness, modulus, tear strength, abrasion resistance. |

| Thermal Performance | Thermal conductivity, thermal expansion, stability. |

| Electrical Performance | Conductivity, dielectric constant (for conductive nanoparticles). |

| Optical Performance | Transmittance, refractive index, fluorescence (for optically active nanoparticles). |

| Biocompatibility | Cytotoxicity, hemocompatibility (for biomedical use). |

| Other Specific Performance | Flame retardancy, chemical resistance, aging resistance (per application needs). |

What are the applications of Silicone Nanoparticle-Embedded Reactive Molding?

Silicon nanoparticle-embedded reactive molded composites offer versatile applications across multiple industries due to their enhanced properties. The following table summarizes their key uses in automotive, electronics, healthcare, aerospace, and consumer goods sectors.

| Industry | Applications |

| Automotive | High-performance seals/O-rings with enhanced wear/weather resistance. |

| Thermal conductive silicone gaskets for battery/electronic cooling. | |

| Sensor components with unique electrical/optical properties. | |

| Electronics | High-thermal-conductivity encapsulants for ICs/power devices. |

| Substrates/encapsulants for flexible electronics. | |

| Insulating materials with specific dielectric properties. | |

| Healthcare | Drug delivery systems using porous silicon nanoparticles. |

| Tissue engineering scaffolds with improved biocompatibility/cell adhesion. | |

| Biosensors with nanoparticle-enabled biorecognition/signal amplification. | |

| Aerospace | Lightweight, high-strength seals and damping components. |

| High-temperature, radiation-resistant cable insulation. | |

| Consumer Goods | Antibacterial kitchenware/daily products. |

| Self-cleaning surface coatings. | |

| Flexible components for wearable electronics. |

What is the Market Potential of Silicone Nanoparticle-Embedded Reactive Molding?

Silicone nanoparticle-embedded reactive molding, combining nanotechnology with reactive molding processes, has the potential to become a high-growth emerging market. Embedding silicon nanoparticles into silicone matrices can significantly enhance the material’s properties, meeting the demand for more advanced functional materials.

The market’s growth will depend on the development of nanoparticle preparation techniques, surface modification technologies, uniform dispersion methods in silicone, and effective integration with existing molding processes. Collaboration among material suppliers, equipment manufacturers, research institutions, and end-users is essential.

Success in expanding the market will rely on overcoming challenges such as the cost, dispersion, long-term stability of nanoparticles, and ensuring the safety of the final products. At the same time, there are opportunities to leverage performance improvements and explore new application areas.

Conclusion

Silicone nanoparticle-embedded reactive molding offers significant advantages in improving the properties of silicone materials. By integrating nanoparticles, manufacturers can create highly functional composites with enhanced thermal, mechanical, and electrical properties. As the technology develops, it has the potential to revolutionize a wide range of industries.

Need a custom silicone solution? With years of expertise in silicone production, we specialize in creating durable, customized solutions tailored to your needs. Contact us today to get started!