Silicone O-rings play a crucial role in countless applications across various industries. These small, unassuming rings are designed to create a reliable seal, preventing leaks and ensuring optimal performance. In this guide, we will explore the properties, applications, advantages, and manufacturing process of silicone O-rings. We’ll also delve into the importance of quality management and after-sales service. So, let’s dive in!

Introduction to Silicone O-Rings

Definition and Purpose

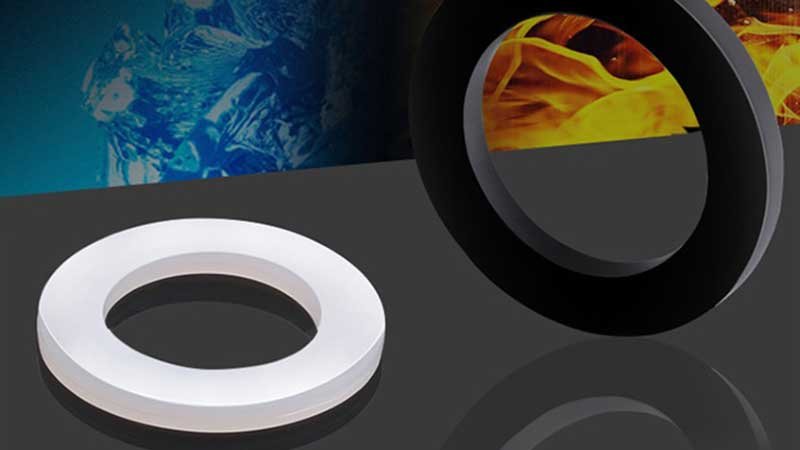

O-rings are donut-shaped seals made from different materials. Silicone O-rings, specifically, are crafted from high-quality silicone, a versatile and durable material. These rings are designed to fit into a groove, creating a tight seal between two mating surfaces. They are widely used across industries due to their excellent sealing capabilities and resistance to extreme conditions.

Overview of Silicone as a Material

Silicone is a synthetic polymer known for its unique properties. It offers high temperature resistance, chemical compatibility, and excellent elasticity. These characteristics make it an ideal material for O-rings, ensuring reliable sealing performance in demanding environments.

Importance of Silicone O-Rings

Silicone O-rings find applications in diverse industries, including automotive, aerospace, medical, industrial machinery, plumbing, and HVAC systems. Their role in maintaining sealing integrity and preventing leaks is vital to ensure optimal performance and safety.

Properties of Silicone O-Rings

High Temperature Resistance and Thermal Stability

Silicone O-rings exhibit remarkable resistance to elevated temperatures. They can withstand extreme heat without losing their sealing properties or deforming, making them suitable for applications in engines, exhaust systems, and other high-temperature environments.

Chemical Compatibility and Resistance to Fluids

Silicone O-rings demonstrate excellent chemical resistance, allowing them to withstand exposure to various fluids, including oils, fuels, solvents, and acids. This property ensures long-term durability and reliable sealing performance in chemically aggressive environments.

Excellent Sealing Capabilities and Elasticity

One of the key advantages of silicone O-rings is their ability to create reliable seals even under low pressure. Their elastic nature enables them to deform and conform to irregularities on mating surfaces, effectively sealing off gaps and preventing leaks.

Durability and Long Lifespan

Silicone O-rings are known for their durability, offering extended service life in demanding conditions. They exhibit resistance to aging, weathering, and UV radiation, ensuring their effectiveness and reliability over an extended period.

Applications of Silicone O-Rings

Automotive Industry: Examples of Silicone O-Ring Usage

In the automotive industry, silicone O-rings are widely employed in engines, transmissions, cooling systems, and fuel systems. These rings provide critical sealing functions, ensuring efficient operation and preventing fluid leaks that could lead to component failure.

Aerospace Industry: Ensuring Reliability in Extreme Conditions

Silicone O-rings play a vital role in the aerospace sector, where they are subjected to extreme temperature variations, high altitudes, and intense pressure differentials. They provide reliable sealing in aircraft engines, hydraulic systems, and fuel systems, contributing to the overall safety and performance of aerospace components.

Medical Devices: Maintaining Sterility and Preventing Leakage

Silicone O-rings find extensive use in medical devices, such as infusion pumps, ventilators, and surgical instruments. These rings provide a secure seal, preventing contamination and fluid leakage, thus ensuring the integrity and safety of medical equipment and procedures.

Industrial Machinery: Sealing and Preventing Contamination

In industrial machinery, silicone O-rings are essential for sealing hydraulic systems, pumps, valves, and other critical components. They protect against fluid leaks, prevent contamination, and maintain efficient operation in challenging industrial environments.

Plumbing and HVAC Systems: Resisting Water and Chemical Exposure

Silicone O-rings are widely utilized in plumbing and HVAC systems due to their resistance to water, chemicals, and temperature fluctuations. They ensure tight seals in pipes, fittings, and valves, preventing leaks and maintaining the integrity of plumbing and HVAC installations.

Advantages of Silicone O-Rings

Versatility and Compatibility with Diverse Environments

Silicone O-rings excel in various operating conditions, making them highly versatile. They can withstand both high and low temperatures, making them suitable for applications that experience extreme heat or cold. Additionally, silicone O-rings exhibit excellent compatibility with a wide range of fluids and chemicals, ensuring their effectiveness in diverse environments.

Cost-Effectiveness and Long-Term Value

Investing in silicone O-rings offers long-term cost savings. Their durability and resistance to wear and tear reduce the need for frequent replacements, resulting in lower maintenance costs. Moreover, their reliable sealing performance helps prevent costly fluid leaks and system failures, saving both time and resources.

Reduced Maintenance and Downtime

Silicone O-rings require minimal maintenance due to their robustness and long-lasting properties. This reduces the frequency of downtime for repairs and replacements, allowing operations to run smoothly and maximizing productivity.

Superior Performance Compared to Other Materials

When compared to alternative sealing materials, silicone O-rings often outperform them in terms of temperature resistance, chemical compatibility, and sealing capabilities. Their elastic nature allows them to maintain consistent sealing performance over a wide range of conditions, ensuring enhanced reliability.

Manufacturing Process of Silicone O-Rings

Raw Material Selection and Formulation

The manufacturing process of silicone O-rings begins with careful selection of high-quality silicone materials. Various factors, such as temperature range, chemical resistance, and application-specific requirements, are considered during material formulation to ensure optimal performance.

Injection Molding or Compression Molding Techniques

Silicone O-rings are typically produced through injection molding or compression molding techniques. Injection molding involves injecting molten silicone material into a mold, while compression molding involves placing the material in a heated mold and applying pressure. Both methods result in precise and consistent O-ring shapes.

Quality Control and Testing Procedures

To ensure the highest standards of quality, silicone O-ring manufacturers employ rigorous quality control measures. These include conducting visual inspections, dimensional checks, and performing tests to evaluate properties like hardness, compression set, and tensile strength. Compliance with international quality standards and certifications, such as ISO 9001, further ensures the reliability of the produced O-rings.

Packaging and After-Sales Service

Silicone O-ring manufacturers pay attention to packaging to protect the O-rings during transportation and storage. Additionally, reputable manufacturers offer comprehensive after-sales services, including technical assistance, warranty coverage, and responsive customer support. This commitment to customer satisfaction ensures a seamless experience and reinforces the manufacturer’s reputation.

Quality Management and After-Sales Service

Importance of Quality Management in Silicone O-Ring Manufacturing

Quality management is of utmost importance in silicone O-ring manufacturing. Stringent quality control processes are implemented at every stage, from material selection to production and testing. This ensures that the final product meets or exceeds industry standards, providing customers with reliable and high-performance O-rings.

ISO Certifications and Adherence to Industry Standards

Leading silicone O-ring manufacturers prioritize quality by obtaining ISO certifications, such as ISO 9001. These certifications demonstrate their commitment to quality management systems and adherence to international standards. Customers can have confidence in the reliability and consistency of O-rings from certified manufacturers.

After-Sales Support, Warranty, and Technical Assistance

Reputable silicone O-ring manufacturers provide comprehensive after-sales support to their customers. This includes warranty coverage for product defects, technical assistance for proper installation or usage, and responsive customer service to address any concerns or inquiries. Such support ensures a positive customer experience and fosters long-term relationships.

FAQs

Q: What are silicone O-rings used for?

A: Silicone O-rings are widely used for sealing applications in various industries such as automotive, aerospace, medical, industrial machinery, plumbing, and HVAC systems. They create a reliable seal, preventing leaks and ensuring optimal performance.

Q: What are silicone O-rings for piercings?

A: Silicone O-rings are sometimes used in body piercings as a comfortable and flexible option. They can be placed on jewelry, such as earrings or nose rings, to secure them in place.

Q: Are silicone O-rings FDA approved?

A: Silicone O-rings made from medical-grade silicone are typically FDA approved for use in specific medical and food-related applications. It is important to check the specific certifications and approvals of the silicone O-rings before using them in sensitive environments.

Q: What is the best O-ring material for high temperature?

A: Silicone is often considered one of the best O-ring materials for high-temperature applications. It can withstand temperatures ranging from -55°C to 232°C (-67°F to 450°F) while maintaining its sealing properties.

Q: Why are silicone rings better than metal?

A: Silicone rings offer several advantages over metal rings. They are lightweight, comfortable, and flexible, making them ideal for active individuals or those with metal allergies. Additionally, silicone rings are non-conductive, making them safer in certain environments.

Q: How long do silicone O-rings last?

A: The lifespan of silicone O-rings depends on various factors such as application conditions, exposure to chemicals or fluids, and maintenance. In general, well-maintained silicone O-rings can last for several years, providing reliable sealing performance.

Q: Do O-rings prevent leaks?

A: Yes, O-rings are specifically designed to create a tight seal, preventing leaks between mating surfaces. They are widely used in applications where preventing fluid or gas leakage is crucial.

Q: Are silicone rings strong?

A: Silicone rings possess good tensile strength and durability. While they may not be as strong as metal rings, they are designed to withstand the rigors of everyday wear and tear.

Q: What is the difference between O-ring and sealing ring?

A: The terms “O-ring” and “sealing ring” are often used interchangeably to refer to the same type of seal. Both terms describe a ring-shaped seal used to prevent leaks between mating surfaces.

Q: What temperature does an O-ring melt?

A: The melting temperature of an O-ring depends on the material used. Silicone O-rings have a relatively high melting point, typically around 200°C (392°F) or higher, which allows them to maintain their integrity and sealing properties under normal operating conditions.

These FAQs provide additional information and address common questions related to silicone O-rings.

Conclusion

Silicone O-rings are indispensable components that play a vital role in achieving reliable sealing and preventing leaks across various industries. Their unique properties, including high temperature resistance, chemical compatibility