Are you curious about the production of silicone products with complex shapes and precise details? Silicone Pneumatic Forming (SPF) is the solution.

We will explore the advantages and applications of silicone pneumatic forming, and compare it with other molding processes, helping you understand which method is best suited for your needs.

What is Silicone Pneumatic Forming

Silicone Pneumatic Forming uses air pressure to help shape silicone material. In this process, liquid silicone is injected into a mold. Air pressure is then applied to push the silicone into all the details and gaps of the mold, ensuring the material forms the desired shape. By controlling the strength and direction of the air pressure, the process ensures that the silicone fills the mold evenly, avoiding bubbles or defects.

This method is especially useful for creating parts with complex shapes or small sizes. It helps achieve high precision and efficiency. Silicone pneumatic forming is commonly used in the production of medical devices, electronic seals, and automotive parts, where accuracy and consistency are crucial.

High-End Markets with Growing Demand for Silicone Pneumatic Forming

Several high-end markets are showing more need for silicone pneumatic forming. The medical industry stands out first. It uses this technology to make advanced parts like flexible implants and precise surgical tools. Demand grows here because these parts must be safe, soft, and exact.

Next, the aerospace sector is picking up interest. They want lightweight, heat-resistant silicone components for aircraft systems. This need increases as planes get more advanced.

The soft robotics field is another big one. Companies use silicone pneumatic forming for flexible robot parts, like grippers and actuators. This market expands fast with more robotics innovation.

Finally, luxury consumer goods are joining in. High-end wearables, like smartwatch straps, rely on this method for style and comfort. These markets grow because silicone pneumatic forming delivers quality and precision they can’t get elsewhere.

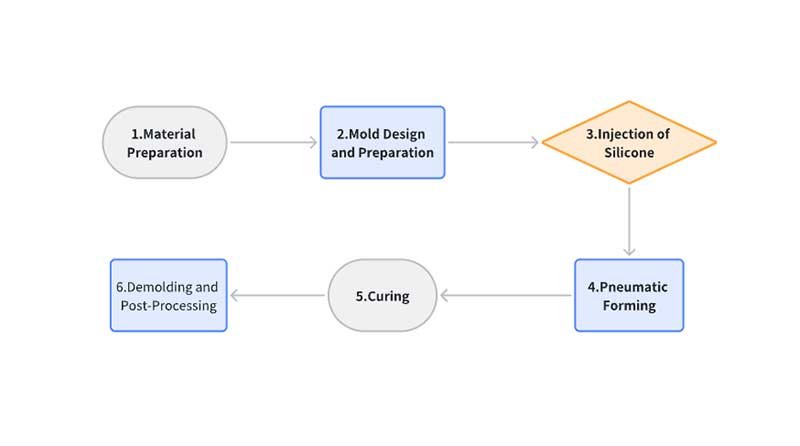

Process of Silicone Pneumatic Forming

- Material Preparation

The first step is to choose the right material, usually liquid silicone rubber (LSR). This silicone has excellent flowability and bonding properties, making it easy to fill complex mold shapes. Before use, the liquid silicone is typically processed to remove any air bubbles and ensure uniformity. This may include mixing, degassing, and heating to prepare the material.

- Mold Design and Preparation

Designing the mold is a important step. A suitable mold is created based on the product requirements. Molds are usually made from heat-resistant metals like aluminum or steel. The mold surface must be smooth and free of defects so that the silicone can easily be removed after curing.

- Injection of Silicone

Once the mold is ready, the liquid silicone is injected into it. This step requires precise control to ensure the silicone fills the mold evenly without creating air pockets. The amount and speed of injection are carefully controlled to suit the mold’s size and shape, ensuring a smooth and efficient process.

- Pneumatic Forming

After the silicone is injected, air pressure is applied to help the silicone fill every part of the mold. The pneumatic system introduces compressed air or gas into the mold. This pressure forces the silicone to fill all the fine details and gaps, ensuring an even distribution. By controlling the air pressure, manufacturers can prevent air bubbles and defects, ensuring a smooth, high-quality finish.

- Curing

The silicone is then cured using heat. The temperature and time are carefully controlled to ensure the silicone fully cures, becoming durable, elastic, and heat-resistant. Typically, the curing process takes from a few minutes to several hours, depending on the type of silicone and the thickness of the product.

- Demolding and Post-Processing

After curing, the silicone product is removed from the mold. Careful removal is necessary to avoid damaging the product. Once demolded, the product undergoes post-processing. This may include trimming excess material, checking the surface for defects, and inspecting the product for quality. Final checks ensure the product meets the required specifications.

Comparison With Liquid Silicone Injection Molding

Silicone Pneumatic Forming (SPF) and Liquid Silicone Injection Molding (LIM) are two commonly used techniques for producing high-precision silicone products. Both methods are employed in various industries, such as medical devices, automotive components, and consumer electronics, but they each have unique features.

The SPF process is known for its ability to create ultra-thin walls and complex geometries, while LIM excels in high-speed production with lower material wastage.

The following table highlights the differences between these two processes, helping businesses select the most suitable method based on their product requirements.

| Comparison Dimension | Silicone Pneumatic Forming (SPF) | Liquid Silicone Injection Molding (LIM) |

| Molding Principle | Compressed air drives silicone flow | Screw injection filling + heat vulcanization |

| Mold Temperature | 160-180°C (Localized gradient control) | 180-200°C (Uniform temperature control) |

| Pressure Range | 0.2-2.0 MPa (Dynamic pressure control) | 15-30 MPa (Constant high pressure) |

| Cycle Time | 90-150 seconds (including cooling and ejection) | 45-80 seconds (high-speed vulcanization) |

| Wall Thickness Limit | 0.08 mm (advantage in ultra-thin areas) | 0.3 mm (limited by shear heat control) |

| Flow Length Ratio (L/T) | 250:1 (strong penetration in complex channels) | 150:1 (high viscosity limits) |

| Material Wastage Rate | 3-5% (cold runner residuals) | 1-2% (hot runner closed-loop control) |

Applications of Silicone Pneumatic Forming

| Application Area | Use Case |

| Medical & Healthcare | Minimally Invasive Devices:Silicone heart occluder seal |

| Bionic Organ Models:Silicone vascular networks for surgery | |

| Consumer Electronics | Waterproof Seals:Sealing rings for TWS earbuds |

| Flexible Touch Modules:Samsung Galaxy Z Fold hinge buffer pad | |

| Automotive Industry | Smart Cockpit Seals:Dynamic sealing strips for roofs |

| Electric Drive System Seals:High-voltage insulation seals | |

| Industrial Equipment | Semiconductor Equipment Seals:Plasma-resistant seals |

| Food Machinery Components:Food-grade silicone components |

Medical and Healthcare Applications

Minimally Invasive Medical Devices

Application Example: Silicone sealing membranes for heart occluders (thickness: 0.1mm ± 5μm)

Technical Breakthroughs: Multi-stage pressure control technology (gradient pressure of 0.05-0.8 MPa) ensures uniform forming of ultra-thin walls. Plasma activation treatment of mold surfaces to eliminate release agent residues, meeting ISO 10993 biocompatibility standards.

Market Status: Leading companies like Medtronic and Boston Scientific dominate the high-end market, with domestic replacement rates being less than 15%.

Bionic Organ Models

Application Example: Silicone vascular networks for surgical training (including simulated blood clot structures).

Process Innovations:Sacrificial layer technology: Water-soluble core molds assist in creating complex cavities. Multi-hardness composite molding (Shore hardness 20A-50A gradient).

Consumer Electronics Applications

Waterproof Sealing Component

Typical Product: Silicone acoustic sealing rings for TWS earbuds (IPX8 waterproof rating).

Process Parameters: 0.3mm ultra-narrow injection slot filling (pressure fluctuation < ±0.05 MPa). Micro-foaming technology (density: 0.9g/cm³, compression permanent deformation < 5%).

Flexible Touch Modules

Technological Benchmark: Samsung Galaxy Z Fold hinge buffer pad (tested for 100,000 folds).

Material Breakthroughs: Graphene-modified silicone (thermal conductivity increased to 5W/m·K). Self-healing silicone (micro-crack repair rate > 90% within 24 hours).

Automotive Industry Applications

Smart Cockpit Sealing Systems

Mass Production Case: Tesla Model Y panoramic sky roof dynamic sealing strip.

Process Challenges: Continuous curvature molding (gradual curvature radius from R50mm to R800mm). Dimensional stability under extreme temperatures (-40°C to 150°C) with thermal expansion coefficient < 200ppm/°C.

Electric Drive System Seals

Technical Specifications: 800V high-voltage system insulation seals (tracking resistance index ≥ 600V).

Material Solutions: Boron nitride-filled silicone (volume resistivity > 1×10¹⁵ Ω·cm). Sandwich structure design (conductive layer/insulating layer/shielding layer co-molded).

Industrial Equipment Applications

Semiconductor Equipment Sealing

Strict Requirements:

Plasma corrosion resistance (mass loss < 0.1mg after 10⁸ RF bombardment cycles).

Ultra-low outgassing (TML < 0.1%, CVCM < 0.01%).

Solution:

Fluorosilicone rubber combined with perfluoropolyether rubber for modification.

Molecular sieve adsorption and demolding (VOCs residue < 1μg/g).

Food Processing Machinery Components

Certification Barriers: FDA 21 CFR 177.2600 + EU 1935/2004.

Process Innovations:

Non-contact electrostatic spraying demolding technology.

Online color difference detection (ΔE < 0.5).

These innovations highlight the versatility of silicone pneumatic forming in various industries, particularly in medical devices, consumer electronics, automotive applications, and industrial equipment. The ongoing development in molding technology and material properties continues to drive progress in these fields, making silicone pneumatic forming an increasingly vital process for high-precision, durable, and cost-effective manufacturing.

Performance Proof of Aerospace-Grade Parts Generated by Silicone Pneumatic Forming

The extreme environmental performance validation system for aerospace-grade silicone components requires establishing a comprehensive multi-dimensional framework, encompassing material screening, extreme environment simulation, functional verification, lifespan prediction, and international certifications.

Through rigorous tests such as thermal-vacuum cycling (-150°C to +200°C), atomic oxygen erosion (5×10¹⁵ atoms/cm²), and 1500G mechanical shock, combined with the Arrhenius acceleration model and fatigue damage accumulation theory, the system ensures silicone components withstand deep-space radiation, extreme temperature fluctuations, and high-vacuum conditions. Compliance with NASA low outgassing certification (TML <1.0%), ESA space suitability reviews, and DO-160G aviation standards is mandatory, establishing a traceable closed-loop data chain.

| Test Category | Simulated Conditions | Test Standards | Key Performance Criteria |

| Thermal-Vacuum Cycling | -150°C to +200°C, 10⁻⁶ Torr, 100 cycles | ECSS-Q-ST-70-02C | Volume change rate <0.5% |

| Atomic Oxygen Erosion | 5×10¹⁵ atoms/cm² (LEO equivalent) | ASTM E2089 | Surface erosion depth <10μm (SEM) |

| Dynamic Sealing Performance | 0→10⁵ Pa cyclic pressure, 10⁶ cycles | ISO 3601-3 | Leakage rate <1×10⁻⁶ cc/sec (He test) |

| Cryogenic Electrical Test | -180°C +10kV sustained discharge | DO-160G Section 25 | Volume resistivity >1×10¹⁴ Ω·cm |

| Radiation Aging | 500 krad γ-ray irradiation | ASTM D1879 | Tensile strength attenuation <20% |

| Lifespan Validation | Arrhenius model (Ea=100kJ/mol) | MIL-HDBK-217F | Equivalent lifespan >15 years (mission) |

Conclusion

Silicone pneumatic forming offers unmatched precision, durability, and flexibility, making it ideal for a wide range of applications. Whether it’s for medical devices, flexible electronics, or advanced automotive components, this technology ensures high-quality, custom-made products with intricate details and reliable performance.