Definition and Basics

Ah, silicone rubber bellows. It’s not your everyday topic of conversation, is it? But hold onto your hats, because these little wonders are game changers! Let’s break it down, shall we?

Silicone rubber bellows are essentially flexible, expandable parts made, unsurprisingly, from silicone rubber. Think of them as the accordion-like structures you’d find in certain instruments. These structures can contract, stretch, and flex without losing their form or function. 🙌

But here’s the kicker: They didn’t just drop out of the sky yesterday. Silicone rubber bellows have evolved over time. They’ve been tweaked, molded, and redefined to suit a myriad of applications. And speaking of applications…

The Many Applications of Silicone Rubber Bellows

Silicone rubber bellows aren’t just for one trick; they’ve muscled their way into a spectrum of industries. Let’s unpack this suitcase of wonders:

- Industrial Machinery: Think of an intricate machine, teeming with parts, exposed to contaminants. Silicone rubber bellows jump in like a superhero, offering protection against the grime and wear. They’re the unsung heroes, the guardians of machinery. 🏭

- Medical Equipment: You’d be surprised, but these bellows are right there in medical devices. Given silicone’s bio-compatibility (that’s a fancy word for saying it gets along with the human body), these bellows ensure everything runs smoothly without any hiccups. Because, let’s face it, no one wants hiccups in a medical setting. 🏥

- Automotive Systems: Vroom vroom! 🚗 From the joints to the connectors, silicone rubber bellows help maintain the car’s flexibility and movement. They ensure everything’s sealed tight, and no unwanted stuff gets in or out.

- Aerospace and Aviation: If it’s flying up in the sky, you bet silicone rubber bellows are involved. They play a pivotal role in fluid control systems, ensuring our flights are smooth and turbulence (from machine errors, at least!) is a thing of the past. ✈️

- Electronics: You love your gadgets, right? Well, guess what shields them from dust and moisture? That’s right, our trusty silicone rubber bellows. They’re like the protective parent of the electronic world. 📱

- Marine Applications: Saltwater can be a beast, eroding and corroding parts. Enter silicone rubber bellows, fighting off the salt and ensuring marine devices stay pristine. A true maritime marvel! ⚓️

Now, that’s a lot of ground covered, isn’t it? From land to sea to air, silicone rubber bellows are truly universal.

Unbeatable Advantages

Alright, pop quiz time! What’s flexible, durable, and laughs in the face of extreme temperatures? You guessed it: Silicone Rubber Bellows. If they were in a superhero league, they’d definitely be leading the charge. Let’s dive into why these bad boys are the top pick for so many applications:

- The Brawny Bellow: Durability is their middle name. Whether it’s combating everyday wear or the occasional rough-and-tough, these bellows flex but never falter.

- Twist and Shout: Oh, the flexibility! Whether you stretch ’em, compress ’em, or contort ’em in crazy ways, they bounce back every. single. time.

- Hot or Not? Doesn’t Matter!: From the icy embrace of winter to the scorching kiss of summer, these bellows remain unfazed. Talk about being cool under fire (or frost!).

- Keep the Bad Stuff Out: Water, UV rays, ozone, and even many aggressive chemicals – nothing fazes these troopers. It’s like having an impenetrable shield.

- Green and Clean: Not only are they tough, but they’re also eco-warriors. Silicone rubber bellows are recyclable, making them a nod to Mother Earth. 🌍

Consumer Concerns Addressed

Alright, alright, let’s hit the pause button. With so much going for them, there’s got to be some concerns, right? Absolutely! As the saying goes, it’s not a party without some uninvited guests. Let’s address some of those lingering questions in your mind:

- Health First: “Is it safe for me? For my family?” Absolutely! Silicone’s bio-compatibility ensures it doesn’t play foul with the human body. But always ensure you’re sourcing from reputable manufacturers.

- Mother Earth’s Advocate: “Is it eco-friendly?” Silicone rubber bellows are recyclable. The industry is committed to reducing the carbon footprint, so you can rest easy. Learn more about our commitment here.

- Value for Money: “Is it going to burn a hole in my pocket?” Let’s be real: initial costs might be a bit more, but in the long run? The durability and reduced need for replacements make it cost-effective. It’s an investment, not an expense!

- The Scent of a… Bellow?: Some folks worry about off-gassing or weird smells. Quality bellows are processed to minimize this. If you’re catching a whiff of something funky, you might want to double-check your source.

There you have it. Advantages that pack a punch and addressing the murmurs of concern. In the realm of bellows, silicone is undoubtedly king. Ready to delve deeper? Let’s roll! 🚀

Innovations and Upcoming Trends

Pop the popcorn and grab a front-row seat, because the silicone rubber bellow world is bursting with drama, action, and… innovation! In an age where technology is advancing at the speed of light, these bellows are not just playing catch-up; they’re setting the pace.

- New Material Mixes: Silicone is amazing on its own, but the real magic is in the blend. Combining it with other materials to get bellows that are tougher, more flexible, and even more resilient. Fusion is the future, baby! Got a thirst for more? Dive into the manufacturing process here.

- Bellow Design Breakthroughs: It’s not just about what they’re made of, but also how they’re shaped. The geometry of bellows is evolving, allowing for even more complex and efficient designs.

- Green Machine: Sustainability is not just a trend; it’s the way forward. With eco-conscious manufacturing and recycling at the forefront, silicone rubber bellows are waving the green flag. 🌱

- Smart Bellows: Embedding sensors and integrating with IoT? Yep, that’s on the horizon. Imagine bellows that can self-diagnose wear and tear or predict maintenance needs. The future is smart!

When Others Compete: A Look at Competing Materials

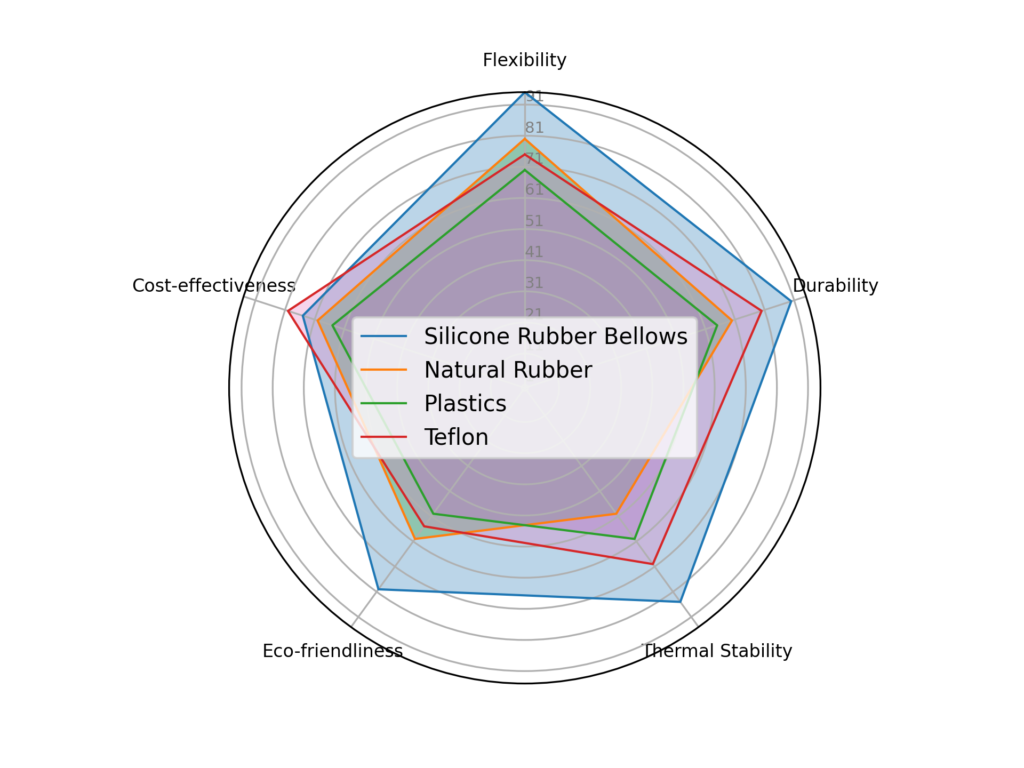

Okay, so silicone rubber bellows might seem like the star quarterback of the material world, but let’s not forget about the other players on the field. How does silicone stand against the tried-and-true classics like rubber or plastics?

- Natural Rubber: An old favorite, for sure. But while it’s flexible and relatively resilient, it can’t quite take the heat (or cold) like silicone can. Plus, ozone? UV? Rubber’s kryptonite!

- Plastics: They’re everywhere, aren’t they? While some high-grade plastics can rival silicone in certain scenarios, they often lack the same level of flexibility and eco-friendliness.

- Teflon and Other Specialized Materials: In some hyper-specific applications, materials like Teflon might get the nod. But in versatility? Silicone bellows still reign supreme.

- Price Wars: Now, while silicone might seem a bit pricier upfront, think long-term. Lesser replacements, higher durability, and reduced maintenance mean you’re getting a bang for your buck!

Sure, every material has its day in the sun. But when it comes to a consistent all-rounder? Silicone rubber bellows are still strutting their stuff on the catwalk of reliability and innovation. Onwards and upwards! 🌟

The Buying Guide: Picking the Perfect Bellow

You’re sold on the idea, right? You’re dreaming of silicone rubber bellows dancing in your head. But how do you pick the right one for your needs? Let’s break down the ultimate shopping checklist for the bellow enthusiasts:

- Purpose and Application: This isn’t a one-size-fits-all game. Will your bellow face high temperatures or chemical exposures? The application dictates the design and material blend.

- Size and Shape: Not all bellows are created equal. The right fit is crucial. Consider dimensions, wall thickness, and even the number of convolutions for optimal performance.

- Quality: Ah, the queen bee of buying. Ensure your bellow comes from reputable suppliers.

- Custom Solutions: Sometimes, off-the-shelf just won’t cut it. Look for suppliers who offer customization – be it in color, design, or even material blends.

- Sample Before You Commit: Testing the waters is wise. Reputable suppliers often provide samples for testing. Intrigued? Grab a free sample here.

- Reviews and Recommendations: What’s the word on the street? Check out customer reviews, feedback, and maybe even drop a question in niche forums.

FAQs: Busting Those Silicone Bellow Myths

Questions swirling around in that head of yours? Fear not! We’re here to slay those silicone rubber bellow myths and quench your burning queries.

- Are Silicone Rubber Bellows Safe for Food & Beverage Use? Yep! But, always ensure you’re sourcing bellows labeled ‘food-grade’. Your evening brew shouldn’t taste like rubber, right?

- Maintenance – Is It a Nightmare? Not at all. One of silicone’s many hats is being a low-maintenance superstar. A regular check and the occasional clean keeps these bellows rocking.

- Can I Get It in Pink? Or Blue? Or… You dream it, they dye it. Silicone rubber bellows come in a vibrant array of colors. Functional and fashionable!

- Is Silicone the Same as Plastic? Nope, not even close. While both might be synthetic, silicone offers far superior flexibility, durability, and thermal stability. Still puzzled? Dive into more answers here.

Choosing the right bellow might seem like a task, but armed with the right info? You’re unstoppable! And always remember: when in doubt, ask it out. Dive into more insights, tips, and bellow brilliance as we continue our journey. Stay flexin’! 💪

Behind the Curtain: The Making of Silicone Rubber Bellows

Let’s unravel the magic. Ever wondered how these flex-phenoms come into being? Here’s a sneak peek:

- Raw Material Selection: It starts with the best of the best. Top-grade silicone is the star ingredient, often mixed with other materials for enhanced properties.

- Design & Molding: Precision is key. Advanced CAD designs guide the mold creation, ensuring every convolution and curve is spot on.

- The Curing Process: Post-molding, the bellows are subjected to high temperatures. This step, known as vulcanization, strengthens the material and gives it that signature flexibility. Here’s the entire silicone manufacturing process.

- Quality Check: Every bellow is inspected, tested, and only the best make the cut. Because compromise? Not in our dictionary. Check out the stringent quality management processes in place.

Wrapping Up: The Future is Flexible

If there’s one thing to take away from this silicone extravaganza, it’s this: the future is flexible. Silicone rubber bellows are more than just a component; they’re a testament to human ingenuity and adaptability.

With industries evolving and technologies advancing, the demand for these all-rounders is only set to soar. They’re bridging gaps, protecting machinery, ensuring seamless operations, and so much more.

Looking to be a part of this silicone saga? Whether you’re a manufacturer, a consumer, or just a curious cat, there’s a world of possibilities waiting. Dive in, explore, and let’s flex into the future together!

So, there you have it, folks! From the ins and outs of silicone rubber bellows to their unbeatable advantages and applications. We’ve covered the A to Z, debunked myths, and looked at what the future holds. Until next time, stay curious and stay flexible! 🚀