Even the best silicone sheets can fail if they’re stored or handled the wrong way.

Proper storage and handling of silicone sheets prevents deformation, contamination, and aging—ensuring long-term performance in critical applications.

I once stored a full roll of silicone sheets in a poorly ventilated room. A few months later, they developed surface dust, discoloration, and warped edges. That mistake taught me that storing silicone properly is just as important as how you use it.

Why Does Proper Storage Matter?

I used to think silicone was nearly indestructible—until I learned how it degrades when exposed to the wrong conditions.

Proper storage preserves silicone sheet flexibility, color, dimensional stability, and cleanliness—especially for food-grade and medical applications.

Silicone is resistant to temperature and aging, but it’s not immune to:

- Dust and contamination from open environments

- UV light exposure which can cause discoloration

- Pressure or folding, leading to permanent creases

- High humidity, which promotes mold on packaging

- Ozone or volatile chemicals, which may react with the surface

This is especially important when the sheet will be used for gaskets, baby products, or medical equipment where performance and cleanliness are critical.

After that early mistake, I started storing all silicone sheets in climate-controlled, shaded storage racks. Since then, I haven’t had a single product failure from material degradation.

What Are the Ideal Storage Conditions for Silicone Sheets?

Not all warehouses are made equal—some can ruin silicone inventory over time.

Store silicone sheets in a clean, dry, dark environment with temperatures between 10°C and 30°C, and humidity below 60%. Keep away from direct sunlight and ozone sources.

Recommended conditions:

- Temperature: 10°C to 30°C (avoid freezing or overheating)

- Humidity: Less than 60% RH (prevent mold on packaging)

- Light: No direct UV or fluorescent lighting

- Ventilation: Avoid air near motors or welding stations (ozone risk)

- Packaging: Keep in original PE bags or dustproof wrap

- Shelf life: Generally 5 years for platinum-cured, 2–3 years for peroxide-cured silicone

Here’s a quick checklist:

| Factor | Ideal Condition |

|---|---|

| Temperature | 10°C–30°C |

| Humidity | <60% RH |

| Light | Avoid direct sunlight |

| Air Quality | No ozone or VOC exposure |

| Surface Contact | Avoid sharp or oily tools |

I always label incoming stock with the date and curing method to track shelf life. For peroxide-cured silicone, I try to use it within 2 years to avoid surface breakdown.

Should Silicone Sheets Be Stored Flat or Rolled?

I once stored thick sheets standing upright. After a few weeks, gravity won—and they slumped.

Store thin silicone sheets rolled on a core and thick sheets flat on a clean, smooth surface to prevent warping or edge curling.

For thin sheets (≤3mm):

- Roll with the smooth side inward

- Use a cardboard or plastic core

- Secure with non-adhesive wrap or straps

- Store horizontally on racks (not standing upright)

For thick sheets (>3mm):

- Store flat on a pallet or shelf

- Use plastic or paper liners between sheets

- Don’t stack more than 10 layers high

- Rotate bottom sheets every few months

Avoid folding silicone sheets. The crease may become permanent, especially in colder environments.

One of my clients had issues with uneven sealing in cut gaskets—turned out the sheets had been folded during storage. We replaced them with flat-packed silicone, and the problem disappeared.

How Should You Handle Silicone Sheets During Production?

Handling seems simple—but it’s easy to contaminate or damage silicone during cutting and assembly.

Always use clean gloves, smooth tools, and dust-free surfaces when handling silicone sheets to avoid contamination or physical damage.

Handling tips:

- ✅ Use cotton or nitrile gloves

- ✅ Clean cutting surfaces before each use

- ✅ Use sharp, clean blades or precision die cutters

- ✅ Avoid dragging the sheet on metal or concrete

- ✅ Store cut parts in labeled, sealed bags

Also consider electrostatic attraction—silicone can attract dust easily. For cleanroom use, I recommend an ionizer or anti-static gun to minimize surface contamination.

When cutting medical-grade silicone for a pump component, we noticed slight yellow streaks. It came from metal shavings left on the table. We now clean all work surfaces with isopropyl alcohol before each cut.

Can Silicone Sheets Be Reused or Recycled?

One customer asked if they could reprocess offcuts from their gasket production. The answer: it depends.

Silicone sheets can be reused or recycled depending on the formulation, exposure history, and cleanliness—platinum-cured silicone is more reusable than peroxide-cured.

Reusing offcuts:

- ✅ Safe if material is clean and uncontaminated

- ✅ Can be used for non-critical seals, pads, or mockups

- ❌ Not suitable for food, baby, or medical products after exposure

- ❌ Avoid using recycled silicone in high-stress or heat-sensitive applications

Some manufacturers regrind and mold industrial-grade silicone into sheets or pads. These are not suitable for regulated industries but can be used for non-contact vibration damping, anti-slip liners, or general sealing.

We sort all production waste. Clean trimmings from food-grade runs are labeled and reused for internal testing or packaging support—not for resale.

What Are Common Mistakes to Avoid?

Some storage and handling mistakes can silently destroy product quality before you even begin production.

Avoid folding, UV exposure, oily hands, dirty tools, or stacking too many sheets—it all affects silicone performance and appearance.

Here’s a list of the most common mistakes I’ve seen:

| Mistake | Result |

|---|---|

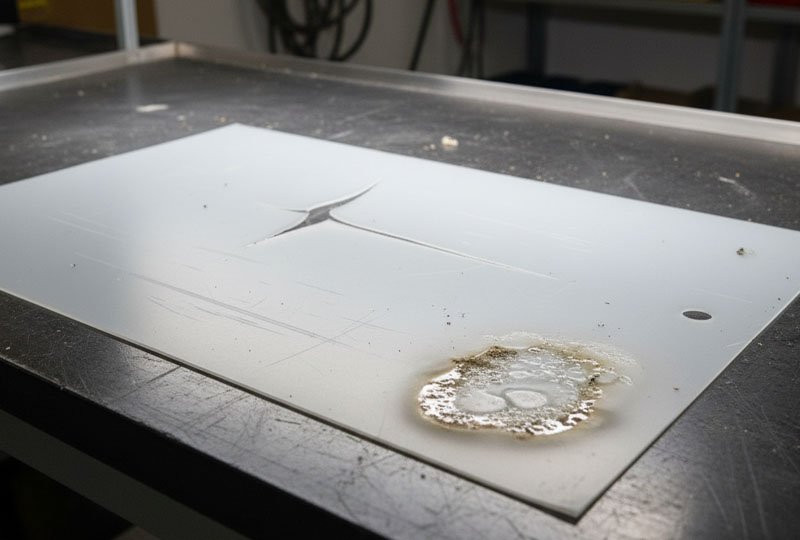

| Folding silicone sheets | Permanent creases or warping |

| Storing near ozone generators | Surface cracking |

| Direct sunlight | Discoloration or hardening |

| Using adhesive tape | Surface damage, residue |

| Stacking heavy weights | Compression marks |

| Bare-hand handling | Fingerprints, oil contamination |

If I’m storing a shipment for more than 3 months, I rewrap each roll in dust-proof film, label the curing date, and move it to a cool, shaded area. Simple steps like this save thousands in rework costs.

Conclusion

Proper silicone sheet storage and handling prevent warping, contamination, and material degradation—ensuring your products meet safety and performance standards.