Silicone rubber strips are a staple in industries that require superior insulation and durability. As a manufacturer specializing in silicone products, I can confidently say that silicone rubber strips are one of the unsung heroes of electrical insulation. They combine flexibility, heat resistance, and electrical insulation properties, making them indispensable in various industries.

In this article, I’ll walk you through the key applications of silicone rubber strips in electrical insulation, why they are preferred over other materials, and how their features make them a go-to choice.

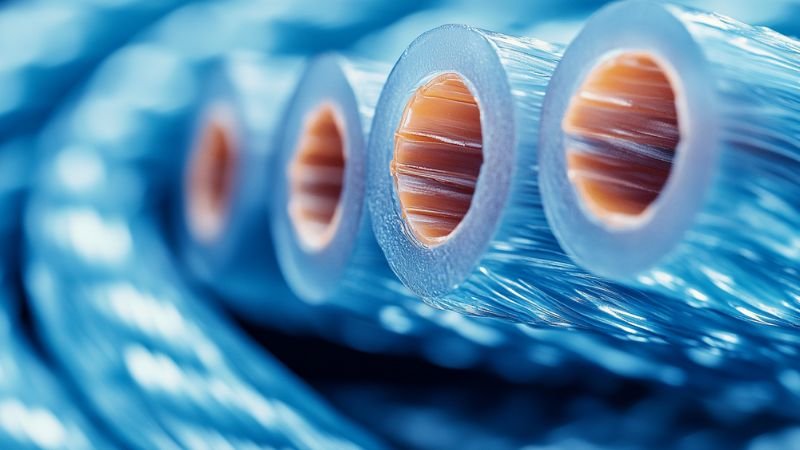

1. Cable and Wire Insulation

One of the most common applications of silicone rubber strips is cable and wire insulation. Silicone rubber is prized for its exceptional dielectric properties, which make it a perfect material for protecting cables in electrical systems. Here’s why:

- High Temperature Resistance: Silicone can withstand temperatures from -60°C to 200°C, which ensures cables remain insulated even under extreme heat. This is vital in industries like aerospace and automotive.

- Durability: Its resistance to wear and tear ensures long-lasting performance, reducing the frequency of repairs or replacements.

- Water Resistance: Silicone is non-porous, so it prevents moisture from compromising the electrical integrity of cables.

In practice, you’ll often find silicone strips being used as insulation covers for high-voltage cables or in environments where wires are exposed to harsh elements.

2. Transformer Insulation

Transformers are at the heart of electrical systems, and their insulation is critical to prevent short circuits and improve energy efficiency. Silicone rubber strips are often used for insulating transformer cores, windings, and other components.

Why silicone rubber for transformers?

- Flexible Sealing: The strips can be molded or cut to size, ensuring a snug fit for irregular shapes and small gaps.

- Thermal Stability: Silicone doesn’t break down under fluctuating temperatures, maintaining its integrity even under heavy transformer loads.

- Electrical Strength: Its dielectric constant ensures efficient energy transfer without losses caused by insulation failure.

By using silicone strips, transformer manufacturers can achieve a balance between reliability and cost-effectiveness.

3. Gaskets and Seals for Electrical Enclosures

Electrical enclosures house sensitive components that must be protected from dust, water, and environmental contaminants. Silicone rubber strips serve as gaskets and seals for these enclosures, ensuring safety and reliability.

Key features:

- Environmental Resistance: Silicone’s natural resistance to UV, ozone, and weathering makes it perfect for outdoor enclosures.

- Compression Set Resistance: Silicone gaskets maintain their sealing properties even after prolonged compression.

- Flame Retardancy: Many silicone formulations are flame-retardant, adding an extra layer of safety.

These gaskets are commonly found in electrical panels, junction boxes, and control cabinets in industrial and commercial settings.

4. Insulation for Heating Elements

Heating elements in appliances like ovens, industrial heaters, and even medical devices require insulation to ensure safety and efficiency. Silicone rubber strips are commonly used as insulating barriers for these heating elements.

Why?

High thermal conductivity ensures efficient heat transfer while protecting adjacent components. Resistance to thermal expansion prevents cracks or deformation under extreme temperatures. For instance, in industrial ovens, silicone rubber strips line the heating elements to insulate them from the metal casing, ensuring energy efficiency and user safety.

5. EMI/RFI Shielding in Electrical Systems

Electromagnetic Interference (EMI) and Radio Frequency Interference (RFI) are challenges in many industries, particularly telecommunications, aerospace, and medical equipment. Silicone rubber strips, when combined with conductive fillers like silver or graphite, act as EMI/RFI shielding gaskets.

How do they work?

- Blocking Electromagnetic Fields: Conductive silicone strips reflect or absorb interference, ensuring that sensitive components remain unaffected.

- Maintaining Electrical Integrity: These strips not only shield but also maintain insulation between different components.

The flexibility and customization options of silicone rubber strips make them ideal for tight-fitting electronic enclosures.

6. Insulation for Power Distribution Systems

High-voltage power distribution systems often require materials that can handle intense electrical loads while providing effective insulation. Silicone rubber strips are widely used in such systems, particularly for:

- Insulating busbars: Busbars are crucial in power distribution. Silicone strips provide a barrier against accidental contact, preventing shorts or arc flash incidents.

- Protecting circuit breakers: Silicone strips are used to line or wrap components, ensuring electrical safety.

Their ability to withstand prolonged exposure to high voltages makes silicone strips a reliable choice for power grids and substations.

7. Solar Panel Applications

Solar panels require efficient insulation to optimize performance and protect against environmental wear. Silicone rubber strips are used in multiple components, including:

- Edge Sealing: To protect the photovoltaic cells from moisture and dust.

- Wire Management: Silicone strips help organize and insulate the wiring system for efficient energy transfer.

These strips contribute to the overall durability of solar systems, ensuring they last for decades under harsh weather conditions.

8. Medical and Laboratory Equipment

In medical and laboratory settings, electrical insulation is a matter of safety and precision. Silicone rubber strips are used in devices like:

- Diagnostic Machines: Insulating high-frequency components to ensure accurate readings.

- Sterilizers and Autoclaves: Providing heat-resistant insulation for electrical circuits.

Silicone’s biocompatibility and food-grade options make it a preferred material for sensitive applications.

Why Silicone Rubber Strips Excel in Electrical Insulation

At this point, you’re probably wondering what sets silicone rubber strips apart from alternatives like PVC or EPDM. Here’s a quick rundown:

- Superior Heat Resistance: Silicone can withstand extreme temperatures without degrading.

- Excellent Electrical Insulation: Its dielectric properties make it perfect for high-voltage applications.

- Long Lifespan: Silicone doesn’t crack, peel, or lose its shape over time.

- Eco-Friendly: Many silicone products are non-toxic and recyclable, aligning with sustainability goals.

Choosing the Right Silicone Rubber Strips for Your Needs

When selecting silicone rubber strips for electrical insulation, consider these factors:

- Temperature Range: Ensure the material suits the operating temperatures of your application.

- Thickness and Width: Choose dimensions that provide effective insulation without adding bulk.

- Certifications: Verify that the silicone meets industry standards like UL 94 or FDA compliance (if needed).

- Customization: Work with a supplier who can tailor the strips to your exact specifications.

At Ruiyang Silicone, we offer a wide range of silicone rubber strips designed for electrical insulation. Our team works closely with clients to develop custom solutions for their unique challenges.

Conclusion

Silicone rubber strips are a versatile and reliable solution for electrical insulation. From cables to transformers, they ensure safety, efficiency, and durability in a wide range of applications. Their unmatched properties, combined with customization options, make them the preferred choice for industries worldwide.

Ready to elevate your electrical systems with premium silicone solutions? Let’s talk.