In the silicone industry, developing custom silicone products requires a full set of professional documents. A complete and well-organized documentation system is key to success.

This article provides a detailed overview of the essential documents needed throughout the development process, from design and materials to manufacturing, quality control, and compliance.

Why Documentation Matters in Silicone Product Development?

Developing custom silicone products involves many steps—design, material selection, tooling, and compliance. Clear documentation keeps everyone aligned, reduces errors, and ensures quality.

It defines the product’s goals, guides production with accurate specs, supports regulatory approvals like FDA or ISO 10993, and makes quality traceable through material and batch records.

Here’s a quick overview of the key files you’ll need along the way.

| Development Stage | Key Documents |

| Design Stage | PSD, 2D Drawings, 3D Models, Renderings |

| Material Stage | Material Data Sheet, Formula Specification, Bill of Materials (BOM) |

| Mold Stage | Mold Design Files, Process Parameter Sheet, Maintenance Plan |

| Quality Control Stage | Quality Control Plan (QCP), First Article Inspection (FAI) Report, Test Reports, Traceability Records |

| Compliance Stage | MSDS, Compliance Declarations, Certification Documents, System Reports |

| Packaging Stage | Packaging Specification Sheet, Label Design Files |

How Can You Get the Concept and Design Stage Right?

The concept and design stage is the first step in making a silicone product. Getting it right helps avoid problems later. Clear and organized documents give your team and suppliers a clear guide to follow.

Product Specification Document (PSD)

This document explains what the product should do and how it should work. It includes the product’s features, performance, regulations, how many to make, and packaging details. A clear PSD helps everyone understand the goal.

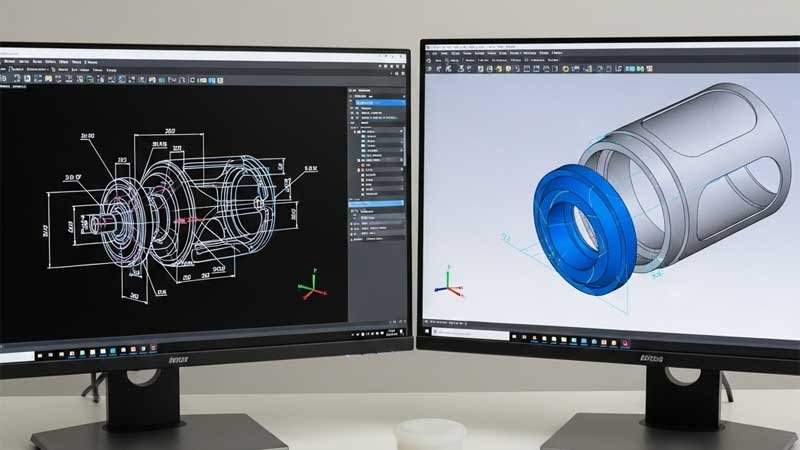

2D Technical Drawings

2D drawings show important details like size, tolerance, and surface finish. They are usually in PDF, DWG, or DXF format. These drawings include front, side, and top views with notes to help make the product correctly.

3D CAD Models

3D models show the product in three dimensions. They help with mold design and checking how parts fit together. Formats like STEP, IGS, or STL let engineers see the shape clearly.

Renderings and Visual Mockups

Renderings show how the final product will look. They include colors, textures, logo position, and usage scenes. These images help with reviews and client approval before making molds.

How Can You Ensure Material and Formula Documents Are Done Right?

Material and formula documents are important. Clear, detailed files help avoid errors and keep production smooth.

Material Data Sheet (MDS)

The MDS lists the physical, chemical, and regulatory properties of silicone raw materials. It covers key data like tensile strength, hardness, transparency, food-grade or medical-grade certifications, and temperature resistance. This sheet helps verify that materials meet your product’s needs.

Formula Specification

This document guides the exact mix of silicone base, fillers, catalysts, pigments, and additives such as anti-mold or antibacterial agents. Accurate formulas ensure the right performance and quality in the final product.

Bill of Materials (BOM)

The BOM details all parts and raw materials used in the product. It supports purchasing, cost control, and formula review. A clear BOM ensures nothing is missed during production and helps manage budgets effectively.

How Can Mold and Manufacturing Documents Improve Efficiency and Consistency?

Well-prepared mold and manufacturing documents help reduce errors, speed up production, and keep product quality stable. When every detail is clearly defined, teams can work faster and more accurately.

Mold Design Files

These files include the mold layout, flow channels, gate positions, draft angles, and venting design. They are usually shared in formats like STEP or IGES, making them easy to use across different teams and tools.

Process Parameter Sheet

This sheet lists the key settings used during molding—such as mold temperature, injection pressure, holding time, and demolding temperature. Keeping these values consistent helps avoid defects and ensures every batch meets the same standard.

Mold Maintenance Plan

To extend mold life and prevent unexpected downtime, regular maintenance is essential. The plan should cover cleaning intervals, wear inspections, and parts replacement schedules. A good maintenance routine keeps production running smoothly.

How Do Quality and Testing Documents Help You Ship Reliable Products?

When making silicone products, especially for babies or medical use, quality needs to be clear and controlled. Simple, well-prepared documents help catch problems early and keep each batch consistent.

Quality Control Plan (QCP)

This plan shows what to check, how to check it, and how many samples to inspect. It covers key points like size, surface, function, and Shore hardness. A good QCP helps make sure inspections follow clear steps every time.

First Article Inspection (FAI)

FAI is used for test runs or first batches. It checks if the product matches the design. The report includes real measurements, surface look, and material tests. This helps fix issues before full production starts.

Test Reports

These reports include strength tests (like pull, tear, and compression) and chemical tests (like odor, migration, or bacteria resistance). They show that your product is safe and meets the required standards.

Traceability Records

These records link each product to its material batch, machine, and operator. If something goes wrong, you can trace it back fast and fix it.

How Do Compliance Documents Help with Export and Certification?

If you want to export silicone products, you need more than just good quality. You also need the right paperwork. Clear, complete compliance documents help you pass inspections, enter global markets, and build trust with customers.

| Document Name | Content Example |

| Material Safety Data Sheet (MSDS) | Lists the chemical makeup and safety details of silicone raw materials. |

| Declaration of Compliance (DoC) | States the product meets standards like FDA, LFGB, REACH, or ROHS. |

| Food or Medical Certifications | Includes FDA 21 CFR 177.2600, USP Class VI, or ISO 10993 for food- or health-grade. |

| Factory System Certifications | Covers ISO 9001, ISO 13485, BSCI, SA8000, and other factory audit qualifications. |

Having these files ready helps speed up approvals and ensures your product can be sold safely and legally in your target markets.

How Do Packaging and Labeling Files Help Keep Products Safe and Share Key Information?

Good packaging isn’t just about looks. It protects your product and tells people what they need to know. That’s why clear, well-made packaging and label files are important at every step.

Packaging Specification Sheet

This file explains how the product should be packed. It shows the type of packaging, layer setup, box size, and how many pieces go in each carton. It may include plastic bags, blister trays, inner supports, and drawings of the outer box. With clear instructions, your supplier can pack everything properly and consistently.

Label Design File

Usually provided in AI or P format, this file shows the brand logo, instructions, batch number, and required symbols like CE or recycling marks. Good labels make your product look professional and ensure it meets all rules.

Conclusion

Developing custom silicone products is a complex process that requires clear, professional, and comprehensive documentation. A standardized document system not only reduces communication costs but also improves quality, efficiency, brand professionalism, and market competitiveness.

If you’re working on a custom silicone project, this article can serve as a helpful checklist. With our experience in silicone manufacturing, we’d be happy to support your production needs.