Healthcare facilities struggle with dangerous pathogen transmission on high-touch surfaces. Standard cleaning protocols often fail to provide continuous protection, leading to healthcare-associated infections that endanger patients and increase treatment costs.

Anti-microbial coatings for silicone sheets incorporate active ingredients like silver ions, quaternary ammonium compounds, or copper that continuously kill or inhibit microorganisms. These specialized coatings reduce bacterial loads by 99.9% within 2-24 hours, maintain efficacy for 6-36 months, and are particularly valuable for medical devices, food processing equipment, and high-touch surfaces.

After helping dozens of medical device manufacturers implement anti-microbial solutions, I’ve seen firsthand how these specialized coatings transform silicone components from potential contamination vectors into active protection barriers. Let me share what makes these coatings so valuable in today’s infection-conscious world.

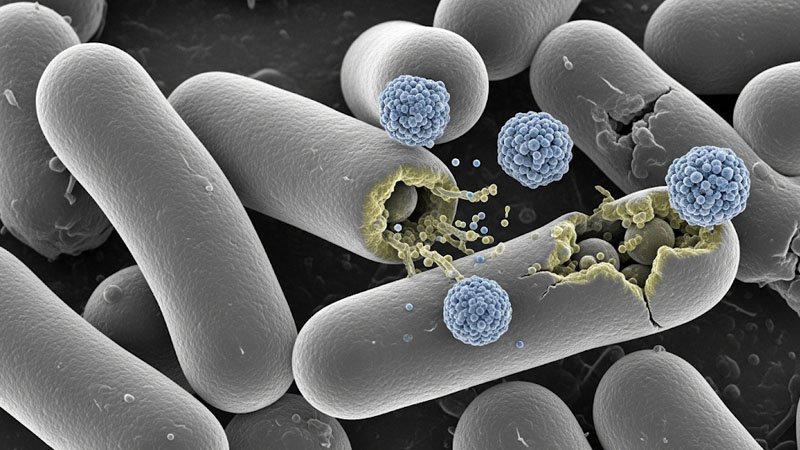

How Do Anti-Microbial Coatings Actually Work?

Medical professionals often assume standard disinfection is sufficient protection against pathogens. However, surfaces become recontaminated within minutes after cleaning, creating ongoing infection risks between disinfection cycles.

Anti-microbial coatings for silicone sheets work through multiple mechanisms including ion exchange, oxidation, and cell membrane disruption. These technologies actively release antimicrobial compounds or create surface conditions that physically destroy microorganisms through contact, providing continuous protection between regular cleaning procedures.

The Science Behind Continuous Protection

The effectiveness of anti-microbial coatings stems from their active mechanisms rather than passive barriers. I recently consulted with John’s company on implementing these coatings for their silicone baby products, helping them achieve a 99.7% reduction in bacterial contamination during product testing.

Anti-microbial technologies for silicone generally fall into three categories:

1. Ion-Based Technologies

Silver ions are the most widely used antimicrobial agents for silicone applications. These work by:

- Binding to bacterial cell membranes, disrupting cellular functions

- Interfering with DNA replication and enzyme systems

- Creating reactive oxygen species that damage cellular components

Silver-based systems typically reduce microbial populations by 99.9% within 2-24 hours of contact and maintain effectiveness for 6-24 months depending on the formulation and wear conditions.

Other ion-based technologies include copper and zinc, each with specific advantages for particular applications. Copper provides faster kill rates for certain pathogens, while zinc offers additional anti-fungal properties.

2. Organic Antimicrobial Compounds

These include quaternary ammonium compounds (QACs) and triclosan derivatives modified for silicone compatibility:

- QACs physically rupture microbial cell membranes through their charged molecular structure

- Modified triclosan compounds interfere with fatty acid synthesis in microorganisms

- Specialized silane-based compounds create a “bed of nails” effect that physically punctures microbial cells

These systems typically provide faster initial kill rates (often within minutes) but may have shorter effective lifespans (6-12 months) compared to ion-based technologies.

3. Photocatalytic Systems

These advanced coatings use light-activated titanium dioxide or similar compounds that:

- Generate reactive oxygen species when exposed to light

- Continuously self-clean the silicone surface

- Provide both antimicrobial and anti-fouling properties

While highly effective in well-lit environments, these systems have limited application in dark conditions, making them suitable primarily for external or well-illuminated applications.

What Applications Benefit Most From Anti-Microbial Silicone?

Product designers often overlook microbial contamination risks until problems arise. Without proactive antimicrobial protection, silicone components can harbor pathogens, leading to product contamination, odors, staining, and potential health risks.

Anti-microbial silicone sheets provide critical protection in healthcare settings (reducing infection transmission), food processing (preventing contamination), consumer products (controlling odor and staining), and HVAC systems (limiting mold growth). These specialized materials are particularly valuable for immunocompromised populations and high-touch surfaces.

Critical Applications Where Protection Matters Most

The value of antimicrobial silicone varies dramatically by application. For John’s baby products company, implementing these coatings provided both genuine protection and important marketing differentiation in a competitive market.

Healthcare Applications

Medical devices represent the most critical application for antimicrobial silicone:

- Wound contact materials (dressings, adhesives)

- Catheter components and insertion sites

- Respiratory equipment gaskets and seals

- Hospital bed mattresses and padding

- Medical equipment touch interfaces

In these applications, antimicrobial silicone can reduce biofilm formation and help prevent healthcare-associated infections, which affect approximately 1 in 31 hospital patients and cost the US healthcare system billions annually.

Food Processing Equipment

Silicone components in food processing benefit significantly from antimicrobial protection:

- Conveyor belts and transfer points

- Gaskets and seals in processing equipment

- Food preparation surfaces

- Storage container seals

These applications help maintain food safety by reducing cross-contamination risks and extending the clean condition of equipment between sanitization cycles.

Consumer Products

Everyday consumer items increasingly incorporate antimicrobial silicone:

- Baby products (pacifiers, teethers, feeding accessories)

- Kitchen utensils and food storage

- Personal care items

- Phone cases and electronic accessories

- Athletic equipment grips and interfaces

For these applications, the antimicrobial properties provide both hygiene benefits and extended product life by preventing odor-causing bacterial growth and material degradation.

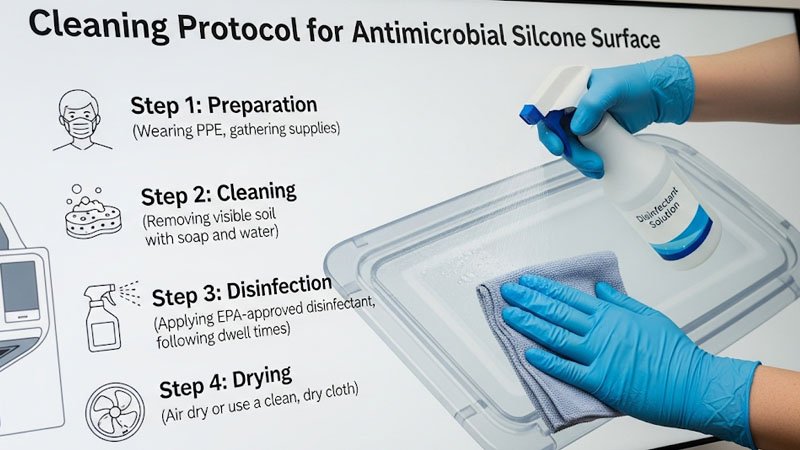

How Do You Maintain Antimicrobial Effectiveness Long-Term?

Facility managers often mistakenly believe antimicrobial surfaces eliminate the need for regular cleaning. This misconception leads to biofilm formation, coating damage, and eventual failure of the antimicrobial protection system.

Maintaining antimicrobial silicone effectiveness requires compatible cleaning protocols, avoiding abrasive materials, monitoring for wear or damage, and implementing scheduled replacement of high-wear components. Even the most advanced antimicrobial coatings require proper maintenance to deliver their full protective potential.

Best Practices for Long-Term Protection

The effectiveness of antimicrobial silicone depends heavily on proper maintenance. When I helped John implement these materials in his production line, we developed specific protocols to ensure the antimicrobial properties would last throughout the product lifecycle.

Key maintenance considerations include:

- Compatible Cleaning Agents

- Avoid quaternary ammonium disinfectants with silver-based antimicrobials

- Use pH-neutral cleaners when possible

- Follow manufacturer recommendations for specific coating types

- Physical Cleaning Techniques

- Avoid abrasive scrubbers that can damage the antimicrobial coating

- Use microfiber cloths for routine cleaning

- Implement proper pressure and motion techniques to minimize coating wear

- Monitoring and Inspection

- Regularly check high-wear areas for coating integrity

- Implement periodic testing to confirm antimicrobial efficacy

- Document cleaning procedures and maintenance activities

- Environmental Considerations

- Control humidity levels to prevent mold growth

- Minimize UV exposure for certain coating types

- Manage temperature extremes that could affect coating performance

With proper maintenance, quality antimicrobial silicone sheets can maintain their protective properties for their entire designed service life, typically 1-3 years depending on the application and wear conditions.

Conclusion

Anti-microbial coatings transform silicone sheets from passive materials into active protection barriers against harmful microorganisms. By incorporating technologies like silver ions, quaternary ammonium compounds, or photocatalytic systems, these specialized materials provide continuous protection in healthcare, food processing, and consumer applications. When properly maintained, they offer significant benefits in infection control, product longevity, and user safety.