Daily sterilization of silicone feeding tools can inadvertently shorten their lifespan. Improper cleaning methods often lead to lingering odors and surface degradation, compromising the product’s safety and long-term utility.

Silicone baby products are generally dishwasher-safe, but hand-washing is the superior method for maximizing longevity and preventing chemical absorption. While dishwashers offer convenience and high-heat sanitization, gentle hand-washing with mild soap prevents the material from absorbing fragrance and protects the surface from abrasive detergents.

In my work with baby product manufacturers, I have analyzed how different maintenance routines impact material integrity. Understanding the technical trade-offs between mechanical washing and manual care is essential for brand quality.

Is it safer to wash silicone baby products by hand or in the dishwasher?

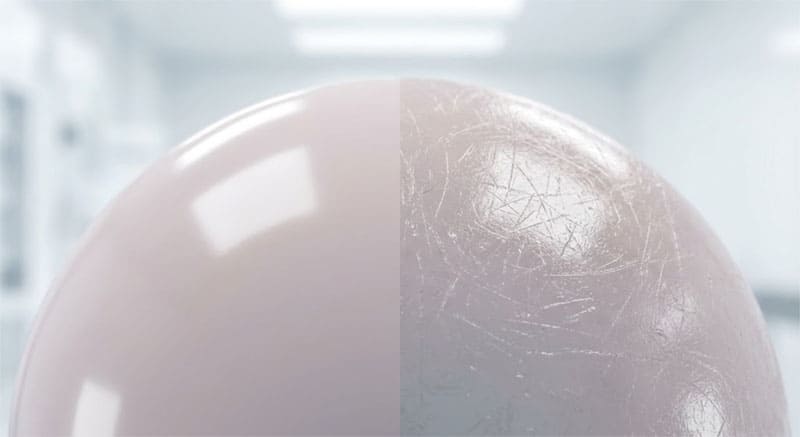

Repeated exposure to aggressive mechanical cycles can microscopic ally damage the surface of food-grade silicone. This degradation creates pockets where bacteria may reside, potentially impacting the hygiene of the infant’s feeding tools.

Hand-washing is safer for preserving the physical integrity of the silicone over hundreds of cycles. The dishwasher is effective for sterilization due to high heat, but the mechanical agitation and harsh chemicals can eventually breakdown the polymer’s protective surface tension.

Surface Tension and Hygiene

When discussing this issue with clients, I notice that the primary concern focuses on the porous nature of silicone. Although silicone is non-porous compared to plastic, it is a “breathable” polymer. Under the high-pressure spray of a dishwasher, the surfactants in commercial detergents can be forced into the material. Throughout my career in silicone manufacturing, I have observed that products subjected strictly to hand-washing maintain their “smooth-touch” finish much longer than those cycled through heavy-duty dishwashers.

Mechanical Stress and Micro-tears

In the factory setting, we perform stress tests on various Shore A hardness levels of silicone. Dishwasher racks, especially those with exposed metal or sharp plastic tines, can cause micro-abrasions during the high-vibration wash cycle. Over time, these tiny scratches become breeding grounds for biofilm. When brands report premature product failure, it is frequently linked to the mechanical stress of dishwasher cleaning rather than the chemical composition of the silicone itself. Hand-washing uses soft sponges which minimize this physical friction, ensuring the product remains smooth and easy to sanitize during its entire functional life.

The Sterilization Trade-off

While hand-washing is gentler on the material, it lacks the sustained high temperatures required to kill certain pathogens. However, most modern silicone is heat-resistant up to 230°C. I often recommend that manufacturers suggest a hybrid approach: daily gentle hand-washing supplemented by a weekly high-heat dip in boiling water. This provides the sterilization benefits of a dishwasher without the constant exposure to abrasive detergents and mechanical wear.

How does high dishwasher heat affect the longevity of food-grade silicone?

Excessive heat exposure during the drying cycle can cause silicone to become brittle or lose its structural elasticity. Over time, this results in warping or cracking that renders the product unusable.

High dishwasher heat, particularly in the “heated dry” phase, accelerates the aging process of silicone. While the material is heat-stable, frequent fluctuations between high-heat water and intense dry heat can eventually cause the silicone to lose its flexible properties.

Thermal Expansion and Contraction

Based on feedback from product development teams, the most damaging part of the dishwasher is not the hot water wash, but the drying cycle. Most dishwashers use an electric heating element at the bottom to dry dishes. This concentrated dry heat is far more aggressive than steam. Across different projects, I have seen that silicone placed on the bottom rack, closer to the heating element, exhibits signs of “chalking”—the appearance of a white powdery residue—much faster than items placed on the top rack.

Structural Deformation and Warping

In my professional observation, thin-walled silicone items like nipple shields or collapsible bowls are the most susceptible to heat damage. While the material will not melt, the internal molecular bonds can weaken. This leads to a loss of the “snap-back” quality that parents expect from high-quality silicone. When I consult with brands on product design, we often discuss wall thickness specifically to combat the warping effects of domestic dishwasher cycles. If the wall is too thin, the heat will cause the item to lose its ergonomic shape.

Long-term Material Fatigue

Manufacturing data suggests that silicone has a high thermal threshold, but “thermal fatigue” is a real phenomenon. Repeatedly Heating the material to 70°C and then allowing it to cool rapidly creates internal stress. In the lab, we see that hand-washing in lukewarm water maintains the original Shore hardness of the material for significantly more cycles. For companies looking to market “lifetime” products, advising against the heated dry cycle is a key strategy to reduce warranty claims and product returns.

Can harsh dishwasher detergents cause silicone items to retain chemical odors?

Standard dishwasher pods often contain heavy fragrances and drying agents that bond with the silicone surface. This leads to a persistent “soapy” taste in food, which is a common technical complaint.

Yes, harsh detergents are the primary cause of odor retention in silicone. The surfactants and essential oils in detergents can permeate the silicone matrix. Once absorbed, these chemicals are difficult to remove and can leach back into food when the item is reheated.

The Science of Absorption

Many brands I work with mention that their customers report a “soapy taste” in their baby’s silicone bowls. This is rarely a fault of the silicone itself, but rather an interaction with the dishwasher detergent. Silicone is lipophilic, meaning it attracts fats and oils. Many commercial detergents contain oil-based fragrances or surfactants designed to make water sheet off plates. These oils cling to the silicone. In my professional experience, standard dishwasher tablets are too concentrated for the delicate balance required for infant feeding products.

Detergent Residue and pH Levels

Most dishwasher detergents are highly alkaline, with pH levels ranging from 10 to 11. This alkalinity is excellent for stripping grease from ceramic, but it can be too aggressive for silicone. High pH levels, combined with the “rinse aids” commonly used in dishwashers, can leave an invisible film on the product. When I analyze returned samples from clients, we often find a buildup of silicate-based residues that have been “baked” onto the item during the drying cycle. This residue is what traps the odors from the detergent.

Comparing Detergent Types

If a client insists on dishwasher compatibility for their product line, I advise them to recommend gel-based, fragrance-free detergents. Powders and pods often contain abrasive particulates that can micro-etch the silicone surface, creating more surface area for odors to latch onto. Through various manufacturing trials, we have found that fragrance-free, plant-based soaps used in hand-washing are significantly less likely to cause this “flavor transfer” issue, protecting the sensory experience of the infant during feeding.

Does consistent hand-washing help prevent color fading and surface degradation?

Brightly colored silicone can lose its aesthetic appeal after repeated exposure to the oxidizers found in dishwasher cleaners. This cosmetic degradation often signals the beginning of functional failure in the material.

Consistent hand-washing preserves the vibrant pigments and smooth surface finish of silicone baby products. By avoiding the oxidizers and aggressive abrasives in dishwasher detergents, the color remains stable and the surface maintains its original slip-resistant and soft-touch qualities.

Pigment Stability and Oxidation

In the silicone manufacturing process, we use specialized pigments to achieve the muted or bright tones popular in the baby market. These pigments are stabilized within the silicone matrix. However, dishwasher detergents often contain oxygen-based bleaching agents. In my work with baby product manufacturers, I have observed that these bleaching agents can slowly oxidize the pigments on the surface of the silicone, leading to a “washed-out” appearance. Hand-washing with pH-neutral soap does not initiate this oxidative process, keeping the products looking new for longer.

Surface Texture Maintenance

Silicone is valued for its unique tactile feel—it is soft, matte, and grip-friendly. The high-pressure spray of a dishwasher, combined with the aforementioned alkaline cleaners, can gradually “polish” the matte finish of the silicone or, conversely, make it feel unpleasantly “tacky.” This change in texture is a sign of surface degradation. When I evaluate samples that have been hand-washed exclusively, the original texture remains consistent even after six months of simulated use. This tactile consistency is a hallmark of quality for high-end silicone brands.

Protecting Graphic Prints and Logos

Many clients use screen printing or laser engraving for logos and measurements on silicone bibs or bottles. The mechanical action of dishwasher water jets can cause printed inks to flake or peel. Even laser-engraved marks can become filled with detergent residue, making them hard to read. From a manufacturing standpoint, hand-washing is the only way to guarantee that these functional and branding elements remain intact through the product’s lifespan. We frequently find that products designated as “hand-wash only” have significantly higher customer satisfaction ratings regarding visual durability.

What are the best practices for hand-washing baby items to ensure total sterilization?

Manual cleaning is often perceived as less hygienic than the high-heat cycles of a machine. However, following a rigorous hand-washing protocol can achieve the same safety standards without the material damage.

Effective hand-washing involves using warm, soapy water and a non-abrasive brush, followed by a separate sterilization step. To ensure total safety, items should be air-dried in a clean environment and periodically boiled or steamed to eliminate any lingering pathogens.

Effective Cleaning Protocols

When I advise brands on including care instructions for their products, I emphasize a two-step process: Cleaning and Sanitizing. Cleaning is the physical removal of food debris and oils using soap and water. I suggest using a soft silicone brush rather than a kitchen sponge, as sponges often harbor bacteria. In my professional observations, using a dedicated “baby-only” basin for washing prevents cross-contamination from other kitchen oils and fats, which is a common cause of the “greasy” feeling parents sometimes report on silicone items.

Optimizing Sanitization Without Damage

To achieve sterilization without the risks of a dishwasher, boiling water is the gold standard in the silicone industry. I recommend submerged boiling for 2 to 5 minutes. This provides a uniform temperature that a dishwasher often fails to reach in every corner of the rack. From a manufacturing perspective, silicone’s USP (Unique Selling Proposition) is its high heat resistance. Utilizing this through a controlled boil is much more efficient and less damaging than a 90-minute dishwasher cycle that includes high-pressure impact and chemical exposure.

Correct Drying and Storage

Based on my experience with material testing, how an item dries is just as important as how it is washed. Silicone should always be air-dried on a dedicated, well-ventilated rack. Drying with a cloth towel can introduce lint and bacteria back onto the clean surface. Many brands I work with have found that advising customers to air-dry their feeding sets vertically reduces the risk of water spots and mold growth in the crevices of complex shapes like sippy cup lids or divided plates.

| Method step | Benefit to Silicone | Sterilization Level |

|---|---|---|

| Mild Soap / Warm Water | Prevents chemical absorption | Low (Cleaning only) |

| Boiling Water Dip | Deep sanitization without wear | High (Sterilization) |

| Air Drying | Avoids lint and cross-contamination | N/A |

How can parents balance convenience and safety when caring for silicone feeding sets?

Managing the cleaning of multiple feeding items daily requires a realistic approach. Finding a middle ground between mechanical convenience and manual material care is necessary for the modern household.

Parents can balance these needs by using the dishwasher for high-use, sturdy items while hand-washing delicate components. Using the top rack and choosing the “air dry” setting reduces heat stress, and periodic deep cleaning removes any detergent buildup.

Setting Realistic Expectations for Durability

In the competitive baby product market, “dishwasher safe” is a required claim for most consumers. However, as a manufacturer, I know that “safe” doesn’t mean “optimal.” I often suggest to clients that they communicate the trade-off to their users. For example, a silicone bib can easily be wiped down or hand-washed in seconds, whereas a complex straw cup might benefit from the high-pressure reach of a dishwasher. By segmenting the items based on their geometry, users can save time without excessively wearing down the entire feeding set.

The “Top Rack Only” Rule

One pattern appears repeatedly in our quality assurance testing: damage is significantly reduced when silicone is kept away from the heating element. I tell all the brands I work with to emphasize “Top Rack Only” in their labeling. This single instruction can double the lifespan of a silicone bowl. Within the manufacturing industry, we understand that the temperature gradient in a domestic dishwasher can vary by as much as 20 degrees Celsius between the top and bottom racks. Using the top rack allows the silicone to be cleaned by the hot water without being “baked” by the heating coils.

Regular Maintenance Cycles

To combat the inevitable accumulation of mineral deposits or soap film from the dishwasher, I recommend a simple monthly refresh. Soaking silicone items in a mixture of white vinegar and water for 30 minutes can strip away the alkaline residues that cause odors. Throughout my years of manufacturing experience, I have found that this simple maintenance step allows parents to enjoy the convenience of the dishwasher for 90% of the time, while the occasional deep soak restores the material’s properties or “resets” the surface chemistry. This balanced approach ensures safety and hygiene while acknowledging the time constraints of the end-user.

Conclusion

While dishwashers offer speed, hand-washing remains the gold standard for preserving silicone quality. A hybrid approach of gentle washing and periodic boiling ensures both product longevity and infant safety.