Are you looking for a material that combines flexibility, durability, and excellent electrical properties? Silicone is the answer. Its unique combination of electrical properties makes it a top choice for many industries, from electronics to automotive.

Why Are Electrical Properties of Silicone Important?

Silicone stands out due to its high dielectric strength, low electrical conductivity, and exceptional thermal stability. These characteristics make it ideal for many applications, ensuring performance under extreme conditions. Let’s explore why silicone is the go-to material for electrical applications.

What Makes Silicone’s Electrical Properties Special?

High Dielectric Strength: Silicone’s ability to withstand high voltages without breaking down is crucial for insulating electrical components. This makes it reliable for high-voltage applications, ensuring safety and performance.

Low Electrical Conductivity: Silicone’s low conductivity prevents the flow of electric current, protecting sensitive components from short circuits and electrical issues.

Thermal Stability: Silicone remains effective as an insulator even at high temperatures, making it suitable for environments where electrical components generate significant heat.

How Does Silicone Insulate Electrical Components?

Silicone’s low electrical conductivity makes it an excellent electrical insulator. This property is essential for protecting electronic components from electrical interference and damage. Its thermal stability ensures continued performance even in high-temperature environments, such as automotive engines and industrial machinery.

Why is Dielectric Constant Important in Silicone?

The dielectric constant measures a material’s ability to store electrical energy in an electric field. Silicone’s low dielectric constant minimizes energy loss, enhancing the efficiency of electrical devices, especially in high-frequency applications.

How Does Silicone Perform Under Extreme Conditions?

Silicone maintains its electrical properties under extreme conditions, whether high heat or freezing temperatures. This resilience makes it suitable for applications like automotive parts and aerospace components, where reliability is critical.

What Are the Advantages of Using Silicone in Electronics?

Silicone is preferred in the electronics industry due to its high dielectric strength and low electrical conductivity, offering excellent insulation and protection for delicate circuits. Its thermal stability ensures components remain protected under high operational temperatures, essential for devices like computers and mobile phones.

How Does Silicone Compare to Other Insulating Materials?

Compared to materials like PVC or polyethylene, silicone excels in high-temperature and high-voltage applications. Its unique combination of electrical and thermal properties makes it more reliable for demanding environments. Additionally, silicone is non-toxic and eco-friendly, adding to its appeal in a sustainability-focused market.

Common Applications of Silicone in Electrical Insulation

- Cable Insulation: Silicone’s flexibility and durability make it ideal for insulating electrical cables, ensuring reliable performance in harsh conditions.

- Connectors and Seals: Silicone insulates electrical connections from moisture and contaminants.

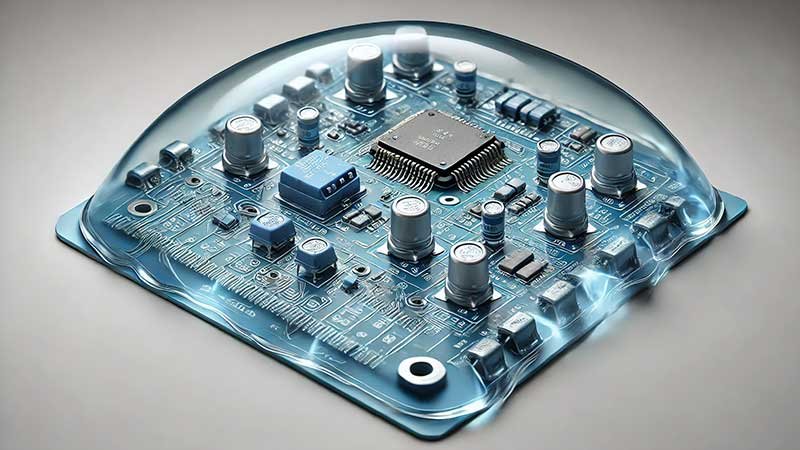

- Circuit Board Coatings: Silicone coatings protect sensitive electronic components from environmental factors.

How Does Silicone Enhance Safety in Electrical Applications?

Silicone’s high dielectric strength helps prevent electrical breakdowns, reducing the risk of short circuits and fires. Its thermal stability ensures it doesn’t degrade at high temperatures, improving the safety and reliability of electrical systems.

Why Choose Silicone for Your Electrical Insulation Needs?

Silicone’s combination of electrical properties, thermal stability, and durability makes it an excellent choice for insulating electrical components. Its eco-friendly nature and customization flexibility offer tailored solutions for your specific needs.

Conclusion

Choosing the right material for electrical insulation is crucial for the performance and safety of your products. Silicone offers a reliable and versatile solution with its exceptional electrical properties. Investing in silicone enhances the performance and safety of your products, ensuring long-term reliability and satisfaction.

Ready to explore how silicone can meet your electrical insulation needs? Contact us today to learn more about our silicone products and customization options.