Imagine a world where machines, appliances, and devices couldn’t keep their contents contained. Chaos would reign as liquids seeped out, gases escaped, and efficiency plummeted. Fortunately, we have a humble yet remarkable invention that ensures such disasters are kept at bay: the silicone gasket.

Silicone gaskets are the unsung heroes of various industries, silently sealing the gaps between two mating surfaces and preventing leakage. From household appliances to automotive engines, medical devices to industrial machinery, silicone gaskets play a crucial role in maintaining functionality and reliability. In this article, we will explore the remarkable qualities of silicone gaskets, their manufacturing process, and the industries that rely on them.

The Basics: What Are Silicone Gaskets?

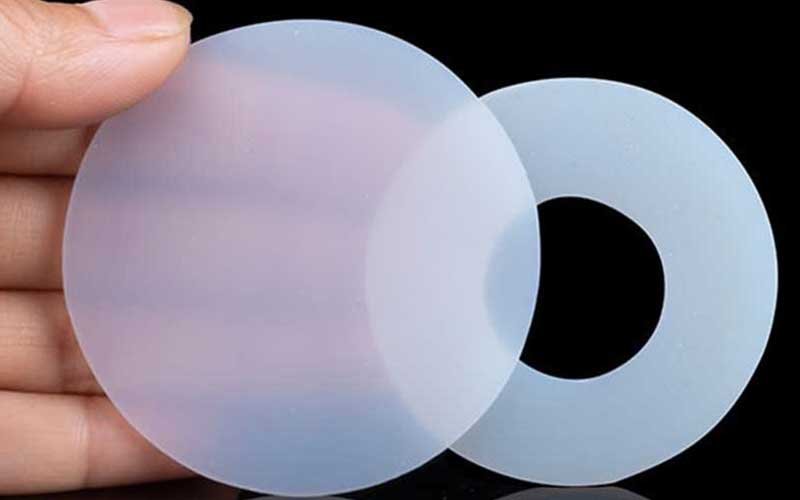

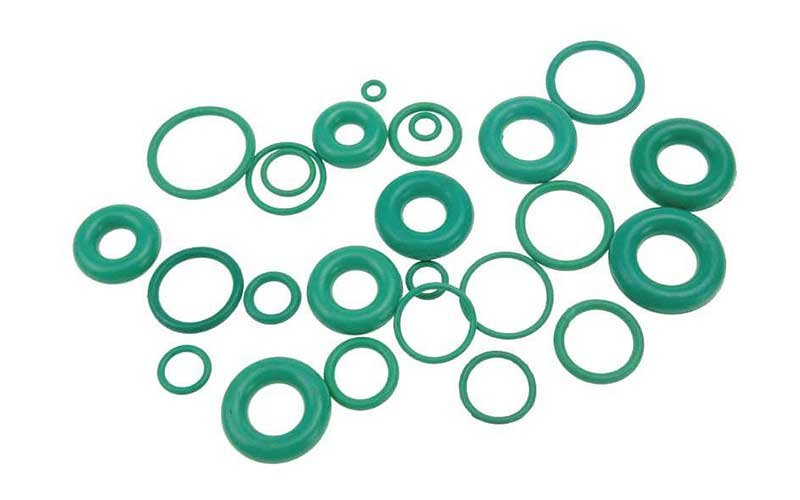

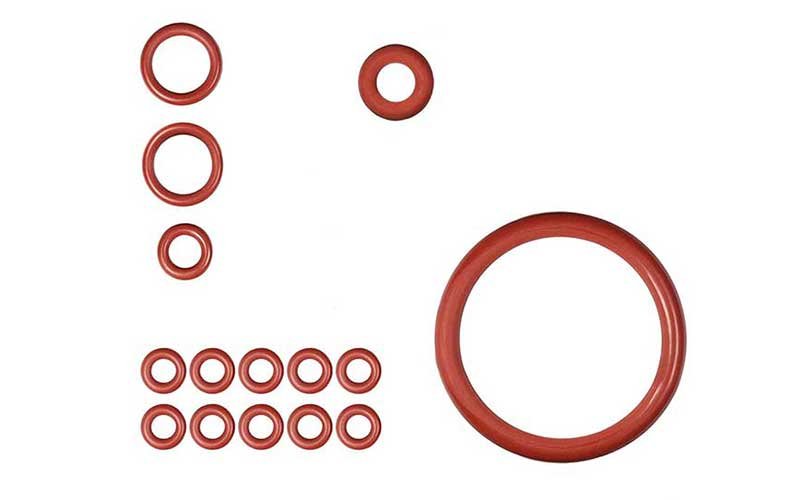

Gaskets, in general, are mechanical seals designed to fill the space between two surfaces, preventing fluid or gas leakage. Silicone gaskets are made from a synthetic rubber-like material called silicone, known for its excellent resilience and versatility. Silicone exhibits remarkable resistance to temperature extremes, UV radiation, moisture, and chemicals, making it a preferred choice for gasket applications.

A Tale of Resilience: The Benefits of Silicone Gaskets

Silicone gaskets offer a wide array of benefits, making them highly sought-after in numerous industries. Let’s dive into some of the key advantages they bring to the table:

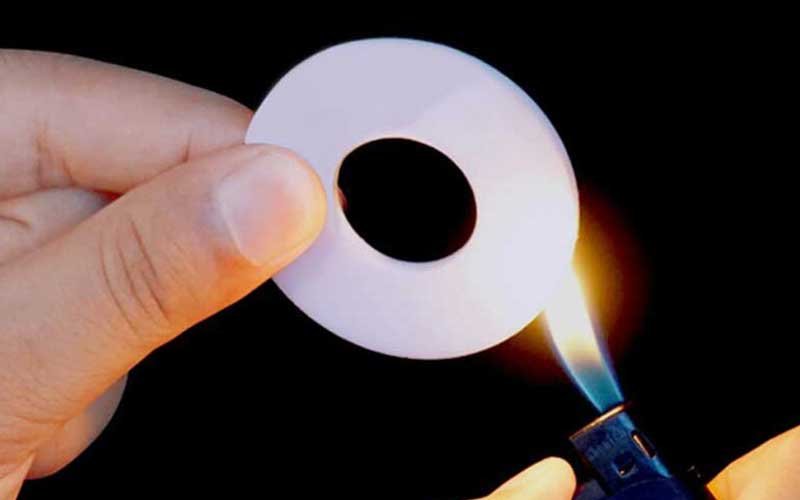

1. Temperature Resistance: From Arctic Chill to Scorching Heat

Silicone gaskets boast an impressive ability to withstand extreme temperatures. Whether it’s subzero temperatures in cold storage facilities or the blistering heat of industrial processes, silicone gaskets retain their elasticity and functionality. This remarkable thermal resistance ensures that sensitive components remain protected and operational, even in the harshest environments.

2. Chemical Resistance: Battling Corrosion and Degradation

Chemical exposure is a common challenge in many industries. Fortunately, silicone gaskets have exceptional resistance to a wide range of chemicals, including acids, alkalis, solvents, and oils. This resistance protects against corrosion and degradation, extending the lifespan of both the gasket and the equipment it seals.

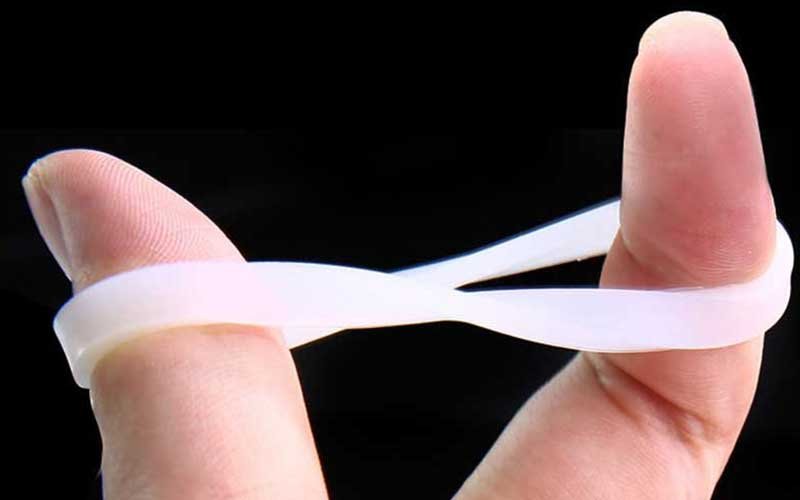

3. Compression Set Resistance: A Long-Lasting Seal

A gasket’s ability to maintain a proper seal over time is critical for preventing leaks. Silicone gaskets excel in this aspect due to their resistance to compression set. Compression set refers to the loss of elastic properties when a gasket is subjected to prolonged compression. Silicone gaskets, however, are known for their remarkable ability to rebound and maintain a reliable seal, even after repeated compression and release cycles.

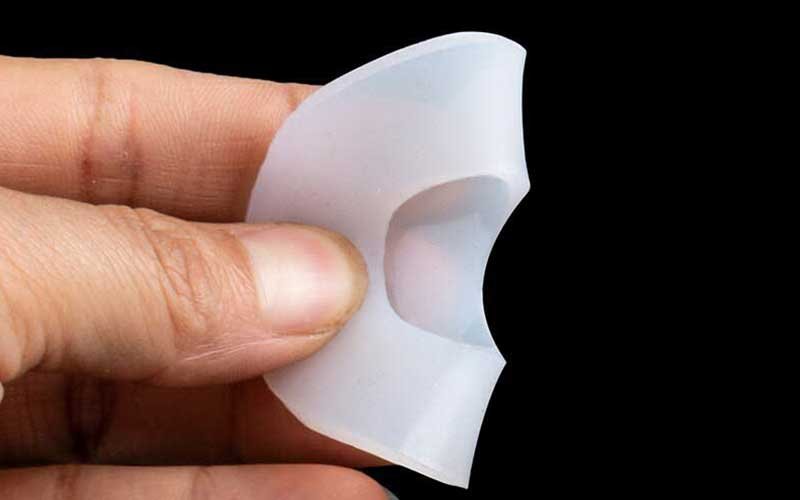

4. Flexibility: Adapting to Uneven Surfaces

Not all mating surfaces are perfectly smooth or even. Uneven surfaces can pose a challenge for gaskets, potentially leading to leakages. Silicone gaskets, with their flexibility and conformability, can adapt to these uneven surfaces, filling in the gaps and providing a secure seal. This versatility allows silicone gaskets to be used in a wide range of applications, accommodating various design complexities.

The Making of a Silicone Gasket

Now that we understand the remarkable qualities of silicone gaskets, let’s delve into their manufacturing process. While the specifics may vary among manufacturers, the general steps involved in silicone gasket production are as follows:

- Material Selection: High-quality silicone material is selected based on the specific requirements of the gasket, taking into consideration factors such as temperature resistance, chemical compatibility, and hardness.

- Material Preparation: The selected silicone material is mixed with additives and catalysts to enhance its properties and ensure proper curing.

- Molding: The prepared silicone compound is placed in a mold, which is typically made from metal or another suitable material. The mold is carefully designed to match the desired gasket shape and dimensions.

- Curing: The mold containing the silicone compound is placed in an oven or subjected to other curing methods, such as UV radiation or heat, to initiate the vulcanization process. This process solidifies the silicone material, giving it the necessary properties for gasket applications.

- Finishing and Inspection: Once the gasket is fully cured, it undergoes finishing processes, such as trimming or post-curing, to achieve the desired dimensions and surface characteristics. Rigorous quality inspections ensure that each gasket meets the required standards before it is ready for use.

Industries Relying on Silicone Gaskets

Silicone gaskets find widespread use across a diverse range of industries. Let’s explore some notable sectors that heavily rely on silicone gaskets to maintain their operations:

1. Automotive Industry

From engines to exhaust systems, silicone gaskets play a critical role in ensuring the efficient and reliable performance of vehicles. Their ability to withstand high temperatures and resist automotive fluids makes them indispensable for applications such as cylinder head gaskets, oil pan gaskets, and exhaust gaskets.

2. Electronics and Electrical Industry

Silicone gaskets provide valuable protection against moisture, dust, and other contaminants in electronic devices, enclosures, and connectors. They help maintain the integrity of the components, ensuring their longevity and reliability in various electronic applications, including smartphones, computers, and control panels.

3. Medical and Pharmaceutical Industry

In the medical and pharmaceutical sectors, maintaining sterility and preventing contamination are of paramount importance. Silicone gaskets are used in equipment such as autoclaves, medical devices, and pharmaceutical processing equipment, providing a reliable barrier against microbial ingress and ensuring the safety and efficacy of products.

4. Food and Beverage Industry

Silicone gaskets find extensive use in the food and beverage industry, where hygiene and product integrity are critical. They are utilized in food processing equipment, storage containers, and beverage dispensers, providing an effective seal and preventing cross-contamination.

Conclusion

Silicone gaskets, with their exceptional resilience, chemical resistance, and temperature tolerance, are indispensable components across various industries. Their ability to create reliable seals between mating surfaces ensures that machines and devices function optimally, preventing leaks, contamination, and inefficiencies. Whether it’s the automotive, electronics, medical, or food industry, silicone gaskets play a vital role in maintaining productivity, safety, and quality.

If you’re in need of silicone gaskets, it’s crucial to partner with a reliable and experienced silicone gasket manufacturer. One such manufacturer is RY Silicone, who specializes in high-quality silicone gasket manufacturing. From their commitment to quality management to their comprehensive after-sales service, RY Silicone ensures that their products meet the highest standards.

Next time you encounter a smoothly functioning device or witness the efficiency of a manufacturing process, remember the humble silicone gasket working silently behind the scenes, preserving order and preventing chaos.

Frequently Asked Questions

Q: Does silicone make a good gasket? A: Yes, silicone makes an excellent choice for gaskets. Silicone gaskets offer flexibility, durability, and resistance to extreme temperatures, chemicals, and UV radiation. Their ability to maintain elasticity and sealing performance over a wide temperature range makes them suitable for a variety of applications.

Q: How to make a silicone gasket? A: The manufacturing process for silicone gaskets involves several steps. First, silicone compounds are mixed with additives and cured in custom molds to achieve the desired shape and size. After curing, the gaskets are trimmed and finished to meet specifications. It is recommended to consult a reputable silicone gasket manufacturer, like RY Silicone, to ensure high-quality and precise gasket production.

Q: What are the disadvantages of silicone gaskets? A: While silicone gaskets offer numerous advantages, they do have a few limitations. Silicone gaskets tend to have a higher initial cost compared to some other materials. Additionally, silicone gaskets may not be suitable for applications requiring high compression set resistance or resistance to certain chemicals. It is important to assess the specific requirements of your application and consult with experts to determine the most suitable gasket material.

Q: Can you use silicone instead of a rubber gasket? A: In many cases, silicone can be used as an alternative to rubber gaskets. Silicone gaskets provide similar sealing capabilities as rubber gaskets but offer additional benefits such as excellent temperature resistance and flexibility. However, it is essential to consider the specific application requirements and consult with professionals to ensure the optimal choice of gasket material.

Q: What is a cheap alternative to silicone rubber? A: Neoprene rubber is often considered a cost-effective alternative to silicone rubber. Neoprene offers good resistance to weathering, oils, and chemicals. It provides similar flexibility and durability to silicone, making it suitable for various applications. However, it is important to evaluate the specific requirements of your project and consult with experts to determine the best material choice.

Q: Do you put silicone on both sides of a gasket? A: The use of silicone sealant on gaskets depends on the specific application requirements. In some cases, applying a thin layer of silicone sealant on both sides of the gasket can enhance the sealing performance and prevent leaks. However, it is essential to follow the manufacturer’s guidelines and consult with experts to determine the appropriate sealing method for your specific application.

Q: How long do silicone gaskets last? A: The lifespan of silicone gaskets can vary depending on factors such as the specific application, operating conditions, and maintenance practices. Generally, silicone gaskets are known for their durability and longevity. With proper installation and regular inspection, silicone gaskets can last for several years, providing reliable sealing performance.

Q: What is the best adhesive for silicone gaskets? A: When it comes to bonding silicone gaskets, using a silicone-based adhesive or sealant is recommended. Silicone adhesives provide excellent adhesion to silicone surfaces, ensuring a strong and reliable bond. It is important to choose an adhesive specifically designed for silicone to ensure compatibility and optimal performance.

Q: What is similar to silicone rubber? A: Several materials share similarities with silicone rubber in terms of flexibility and durability. Some alternatives include neoprene rubber, EPDM (ethylene propylene diene monomer), and fluorosilicone. Each material has its own unique properties and advantages, so it is crucial to evaluate the specific requirements of your application and consult with professionals to select the most suitable material.

Q: Can I use Permatex instead of a gasket? A: Permatex is a brand that offers a variety of sealants and gasket makers. Depending on the specific application and requirements, certain Permatex products can be used as an alternative to traditional gaskets. These products are designed to create reliable seals and prevent leaks. However, it is important to carefully follow the manufacturer’s instructions and ensure compatibility with the specific materials and conditions of your application.

Q: Do silicone gaskets need sealant? A: In most cases, silicone gaskets do not require additional sealant as they are designed to provide effective sealing on their own. However, certain applications or specific conditions may benefit from the use of silicone sealant to enhance the sealing performance and prevent leaks. It is recommended to consult with experts or refer to the manufacturer’s guidelines to determine the need for sealant in your particular application.