When clients ask about medical grade silicone, they usually already know one thing:“Silicone is soft, stable, and widely used in medical products.”

That part is true. The problem is that not all silicone behaves the same once it enters a real medical environment. Heat, sterilization, long-term skin contact, and regulatory review will quickly expose the difference.

Medical grade silicone is used because it performs predictably under these conditions. It is not chosen for marketing reasons. It is chosen to reduce risk.

What matters is not how the material feels on day one, but how it behaves after months of use and repeated processing.

What Exactly Is Medical Grade Silicone?

From an engineering point of view, medical grade silicone is a controlled system, not just a softer rubber.

Compared with general-purpose silicone, medical grade materials are produced with tighter limits on:

- Raw material purity

- Residual catalysts and by-products

- Volatile compounds and unnecessary fillers

In most medical applications, platinum-catalyzed curing is used instead of peroxide curing. This choice is deliberate. Platinum curing produces fewer residues and a more stable polymer structure. That stability becomes important after sterilization or long-term contact with the body.

In practical terms, properly formulated medical grade silicone:

- Does not irritate skin or tissue

- Does not react with blood, drugs, or body fluids

- Maintains its properties after sterilization

That baseline reliability is the reason it is accepted in regulated medical products.

Common Grades of Medical Silicone

| Grade | What It Means in Practice | Typical Uses |

| Non-implantable medical grade | Suitable for external contact or limited internal contact | Masks, oxygen tubing, external catheter components |

| Implantable medical grade | Tested and approved for long-term internal use | Cardiac catheters, prosthetics, implantable devices |

This distinction matters. Medical grade does not automatically mean implantable, and using the wrong grade is a common mistake.

What Is the Difference Between Silicone and Medical-Grade Silicone?

This is where confusion usually starts.

Standard silicone can look and feel identical to medical grade silicone. If you only touch it, you cannot tell the difference.

The real differences appear later:

- After sterilization

- After prolonged skin or fluid contact

- During regulatory review

Standard silicone may include higher filler levels, residual curing by-products, or additives that were never evaluated for biological contact. In many industries, that is acceptable. In medical applications, it is not.

Medical grade silicone is different because:

- Raw materials are traceable

- Extractables and leachables are controlled

- Biocompatibility testing, such as ISO 10993, is part of qualification

In projects we see, material problems rarely appear at the prototype stage. They appear during validation, aging tests, or after repeated sterilization cycles.

Why Medical Grade Silicone Works in Medical Applications?

From an engineering perspective, medical grade silicone solves several practical problems at once.

Biocompatibility

It can stay in contact with skin, blood, and body fluids without causing irritation or adverse reactions.

Elasticity and softness

It conforms to body contours and maintains sealing performance in masks, tubing, and wearable devices.

Sterilization stability

It tolerates steam, boiling, UV, and other common sterilization methods without significant degradation.

Chemical resistance

It does not react with drugs, disinfectants, or bodily fluids, which is critical for fluid-contact components.

Aging behavior

Over time, it resists hardening, yellowing, and surface tackiness, even after repeated sterilization.

These are not abstract properties. They directly reduce failure risk in daily medical use.

Where Medical Grade Silicone Is Commonly Used?

You will typically find medical grade silicone in applications where performance consistency matters more than cost savings.

Respiratory products

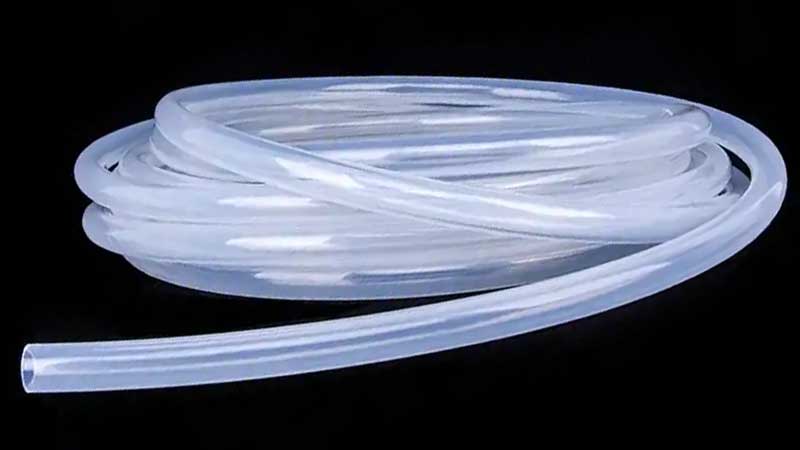

Masks, oxygen tubing, and CPAP interfaces need materials that remain soft and stable through repeated use and cleaning.

Medical tubing and catheters

Drainage tubes, infusion lines, and catheters rely on silicone for flexibility and chemical stability.

Seals and functional components

Valves, diaphragms, and pistons depend on silicone to maintain sealing performance after sterilization.

Wearable medical devices

Monitoring patches and rehabilitation devices require skin-friendly materials for extended wear.

Implantable devices

Implantable-grade silicone is used where long-term stability inside the body is non-negotiable.

How Medical Grade Silicone Is Produced and Controlled?

From a materials standpoint, formulation alone is not enough. Process control is equally important.

Most medical silicones are platinum-cured to minimize residues and volatile by-products. During compounding, fine filtration is often used to remove particles and metal contamination.

Production usually takes place in cleanroom environments. This reduces the risk of contamination that could affect biocompatibility or surface quality.

On the quality side, manufacturers operate under ISO 13485 systems. Materials, batches, and inspections are documented and traceable. This becomes critical during audits or regulatory submissions.

Before use, materials must pass ISO 10993 testing. For higher-risk applications, additional testing for extractables, aging, and sterilization compatibility is often required.

How To Know If Something Is Truly Medical-Grade Silicone?

There is no quick visual test. Verification comes from documentation and experience.

Start by checking material documentation. Medical grade silicone should come with specifications, batch traceability, and ISO 10993 test results.

Confirm the curing system. For most medical applications, platinum curing is expected.

Review the supplier’s quality system. ISO 13485 compliance is a strong indicator that the material is managed for medical use.

Match the grade to the application. External-contact materials are not automatically suitable for implantable use.

Finally, look at supplier experience. Suppliers who regularly support medical projects tend to understand regulatory expectations and common failure points.

Conclusion

Medical grade silicone is not defined by how it feels or how it is marketed. It is defined by control, testing, and long-term behavior.

When the right grade is selected and properly processed, medical grade silicone provides stable performance, regulatory confidence, and predictable results in real medical applications.