Even the best design fails without strict quality control. In silicone keypads, durability, precision, and consistency matter more than you think.

Silicone keypad quality is ensured through rigorous testing—covering tactile feedback, dimensional accuracy, resistance to wear, and environmental stress—to meet the reliability standards of various industries.

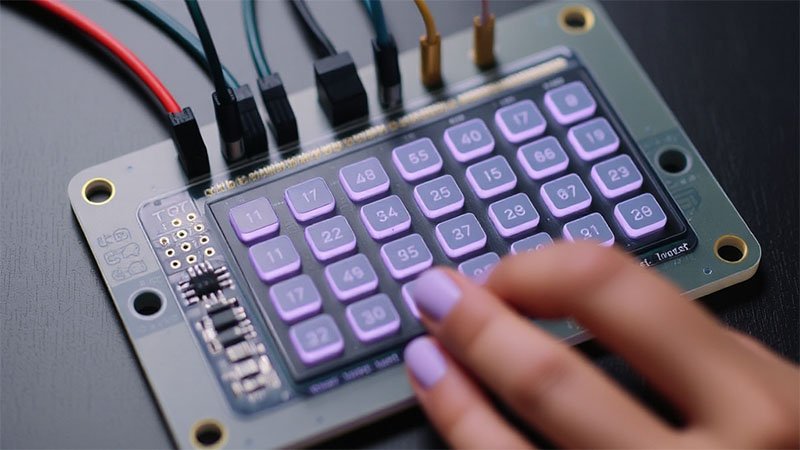

When I work with clients in medical, industrial, or consumer tech industries, they always ask one thing: how do we know the keypads will last? This is where testing and quality control come in. At RuiYang Silicone, we don’t ship anything that hasn’t passed a full checklist. Here’s how we do it.

How is tactile force measured and controlled?

Tactile force defines how the keypad feels in use—it must be both responsive and consistent.

We use a force-displacement testing machine to measure the actuation force, travel distance, and rebound curve of each button to ensure consistent tactile feedback.

Every button has a target tactile force, usually between 100g and 250g, depending on the application. A keypad that feels “off” can make a device frustrating to use.

We use a digital force tester to press each button slowly. It records how much pressure is needed to actuate and the shape of the rebound curve. We compare this against design specs. If the force is too low, it may register false presses. Too high, and the user gets fatigued.

| Parameter | Ideal Range | Purpose |

|---|---|---|

| Actuation Force | 100g – 250g | Comfort and precision |

| Travel Distance | 0.3mm – 1.2mm | Feedback and usability |

| Snap Ratio | 40% – 70% | Defines tactile sharpness |

Only keypads with consistent tactile curves across the board pass.

How do we check for dimensional accuracy?

Precision in dimensions affects how the keypad fits the device housing and aligns with PCB contacts.

Dimensional accuracy is checked with calipers, gauges, and 3D scanners to ensure each keypad matches mold tolerances.

After molding, keypads are inspected for dimensional accuracy. We verify key height, spacing, overall pad thickness, and edge tolerances. Any variation can cause key misalignment, faulty electrical contact, or fitting issues.

We often use digital calipers and customized gauges. For complex shapes, we use 3D scanning to map the surface profile and compare it with CAD models.

| Checkpoint | Tolerance |

|---|---|

| Button height | ±0.05mm |

| Key spacing | ±0.1mm |

| Pad thickness | ±0.1mm |

This step ensures the keypad fits perfectly and interacts reliably with the circuit.

How is wear resistance tested?

Durability is essential—especially for high-use devices like remotes or control panels.

We run abrasion tests, solvent rub tests, and cycle life simulations to evaluate wear resistance of coatings, legends, and silicone surface.

Silicone keypads may face hundreds of thousands of presses, rubbing, and exposure to oils or sweat. We simulate real-world wear with:

- Abrasion testing: using rotary pads to simulate finger friction.

- Solvent resistance testing: rubbing alcohol or cleaners on the printed or coated surface.

- Life-cycle testing: repetitive pressing for up to 1 million cycles.

If the legends fade, coating peels, or keys degrade, the batch fails.

| Test Method | Criteria |

|---|---|

| Abrasion Test | No legend fade after 1000 rubs |

| Solvent Rub Test | No ink transfer in 20 rubs |

| Cycle Life Test | >500,000 presses with no cracks |

This is especially critical for medical, automotive, and industrial applications.

What environmental tests are required?

Keypads must survive heat, cold, moisture, and UV—especially in outdoor or harsh settings.

Environmental testing includes temperature cycling, humidity exposure, UV aging, and water resistance evaluation to simulate field conditions.

We test silicone keypads in temperature chambers, UV ovens, and humidity boxes. This helps predict their behavior in real-world conditions.

- Temperature cycling: from -40°C to +125°C to test flexibility and adhesion.

- Humidity test: up to 95% RH at 60°C to check for swelling or delamination.

- UV exposure: simulates years of sunlight to evaluate fading or cracking.

- Ingress protection (IP): simulates water and dust entry using splash and submersion tests.

| Test Type | Common Conditions |

|---|---|

| Temp Cycle | -40°C to +125°C, 100 cycles |

| Humidity | 95% RH, 60°C for 72 hours |

| UV Aging | 500–1000 hrs simulated exposure |

| IP Rating | IP65 or IP67 for sealed designs |

We simulate worst-case environments to ensure confidence in all conditions.

How do we check for electrical conductivity and contact reliability?

In conductive keypads, poor contact can mean no response or unstable signals.

We test contact resistance using multimeters or custom jigs to ensure consistent signal performance across all conductive pads.

Conductive pills, made from carbon or gold-plated silicone, must provide stable resistance across thousands of presses. We use a test jig with printed circuit boards to simulate electrical contact.

The resistance between the pill and contact pad should be low and stable—usually under 100 ohms. We also check for bounce or delay in response using an oscilloscope when necessary.

| Test | Target Result |

|---|---|

| Contact Resistance | <100 ohms |

| Bounce Time | <10ms |

| Signal Consistency | 99.9% repeat accuracy |

Stable contact ensures the keypad communicates clearly with the device logic board.

What visual inspections are part of final QC?

The final product must look flawless. Any defect in appearance can signal poor craftsmanship.

Visual inspection checks for flash, bubbles, warping, discoloration, misaligned legends, and surface defects before packaging.

Our trained QC team examines each keypad under strong lighting and magnification. We look for:

- Silicone flash or trimming errors

- Legend misalignment or smudges

- Air bubbles under coating

- Surface contamination or color mismatch

We sort batches into pass/fail bins and log results into our quality report system.

| Defect Type | Accept/Reject Criteria |

|---|---|

| Flash/Deformation | <0.1mm max, smooth to touch |

| Legend Alignment | Offset less than ±0.2mm |

| Surface Bubbles | None in critical areas |

| Color Deviation | Within Pantone ±1 delta |

Visual perfection reflects product quality to the end customer.

Conclusion

Silicone keypads undergo extensive testing—from tactile force to environmental stress—to ensure they perform reliably in real-world applications. Quality control isn’t a step; it’s a system we live by.