In today’s market, color strongly influences buyer choice. Natural silicone is usually milky white or semi-transparent. Silicone color masterbatch gives you consistent, controllable color while keeping silicone’s flexibility and safety. It balances appearance with performance.

What is Silicone Color Masterbatch?

Silicone color masterbatch is a concentrated pigment carrier formulated to disperse evenly in a silicone matrix. It contains pigments, a compatible carrier (typically silicone), and small amounts of additives. Properly made masterbatches remain stable during high-temperature vulcanization. Compared with loose pigment powders, masterbatch improves flow and dispersion during processing and avoids negative effects on elasticity or hardness.

There are masterbatches designed for liquid silicone rubber (LSR) and for high-temperature vulcanized silicone (HTV). They work with molding, injection, extrusion, and casting. In short, a silicone color masterbatch is the medium that binds pigment to silicone, ensuring uniform, stable, and repeatable color.

Types of Silicone Color Masterbatch

By Pigment Type

- Inorganic pigments. Bright, heat resistant, and lightfast. Good for outdoor or industrial parts such as seals and external buttons.

- Organic pigments. Offer richer tones and semi-transparent effects. Common in baby products and bakeware where softer colors are preferred.

By Application Form

- Thermoplastic silicone masterbatch (HTV). For solid silicone molding and extrusion.

- Liquid silicone masterbatch (LSR). For liquid silicone injection and casting, typically disperses more uniformly.

By Functional Requirement

- Decorative. Focus on aesthetics for consumer products.

- Functional. Adds UV resistance, anti-mold, anti-static properties, or other performance features for special uses.

Compatibility Between Silicone Color Masterbatch and Base Silicone Materials

Compatibility is more than a checkbox. It directly affects curing and final properties.

- For LSR, the masterbatch must use a fully compatible silicone carrier. An incompatible carrier can inhibit platinum-catalyzed curing, causing incomplete vulcanization, surface tack, or unstable mechanical properties. This risk is critical for medical and baby products.

- For HTV, poor matching can cause uneven dispersion, color streaks, reduced tear strength, or surface defects after molding. In peroxide-cured systems, pigments and additives must tolerate higher curing temperatures without degrading.

- The practical rule is simple: choose masterbatches formulated for your silicone type and curing system. That prevents processing problems and reduces rework.

Advantages of Silicone Color Masterbatch

Silicone color masterbatch brings clear, measurable benefits:

- Uniform color. Pre-dispersion prevents inconsistent coloring from manual pigment addition.

- Processing stability. Properly formulated masterbatches resist discoloration and degradation during high-temperature curing or injection. They preserve elasticity, hardness, and surface finish.

- Safety and compliance.Food-grade and medical-grade pigments can meet FDA, LFGB, ISO 10993, and similar standards.

- Higher production efficiency. Pre-mixed masterbatch cuts on-site handling, lowers labor complexity, and reduces color defects.

Use the right masterbatch and you raise product look, reliability, and brand value.

Usage Guidelines and Precautions

Recommended Dosage and Processing Considerations

Correct use matters. Typical addition is 1%–5% of total silicone weight, adjusted by color and shade. You can mix by dry blending, drum mixing, or add directly to LSR before injection. Key points:

- Control addition. Excessive masterbatch reduces flow and harms molding quality.

- Ensure even dispersion. Poor mixing causes streaks or pigment settling.

- Pick heat-resistant pigments. Choose pigments that survive vulcanization without yellowing or forming bubbles.

Practical Impact of Color Masterbatch on Silicone Properties

Within recommended ratios, masterbatch minimally affects final properties. Still, know the limits.

- Additions above about 5% can start to change tear strength, elongation, or flow.

- Deep or highly saturated colors need more pigment. This can reduce transparency and slightly increase stiffness in thin-walled parts.

- Dark colors absorb more heat. In high-temperature or outdoor use, this can accelerate aging. For long-term thermal stability or weather resistance, test pigment choice and dosage during design.

Understanding these boundaries helps you balance appearance and performance.

Color Consistency and Batch Control in Mass Production

Color consistency is a frequent customer concern, especially for branded or large-volume runs.

- Wall thickness, surface texture, gloss, and molding temperature all change how a color looks on the finished part.

- A Pantone reference is a guide, not a guaranteed match. The molded part may differ because of material and process variables.

- Batch-to-batch control at the masterbatch supplier is crucial. Reliable suppliers maintain tight dispersion and formulation tolerances.

- Always confirm color with molded samples, not just raw material swatches or color codes. For strict color requirements, require sample approval and color retention testing before mass production.

Common Misconceptions

- “More color gives a brighter result.” Overuse can impair flow and elasticity. Brighter is not always better.

- “All masterbatches are safe.” Never assume. Check for food-grade or medical-grade certification when required.

- “Masterbatch changes hardness.” When used correctly, it usually does not. But high loadings can affect some mechanical properties.

Clear expectations avoid repeated trials and warranty claims.

Practical Applications

- Baby products.Pacifiers, teethers, and spoons require food-grade pigments and gentle tones.

- Kitchenware. Baking mats and molds demand heat and oil resistance plus uniform color.

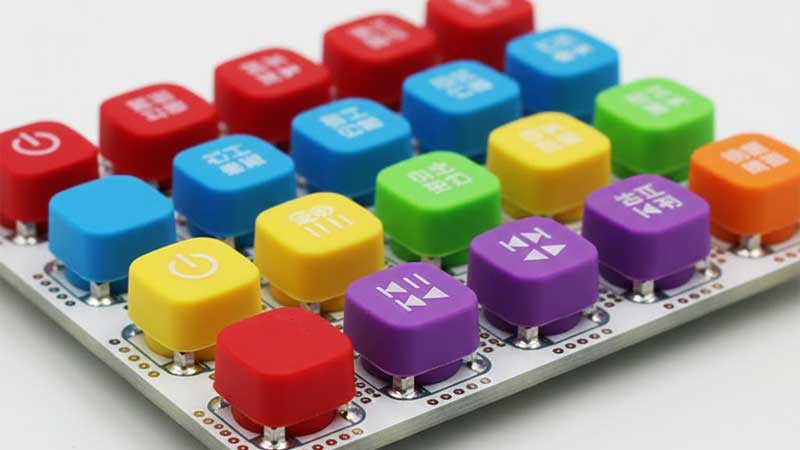

- Electronics. Colored silicone buttons and seals help usability and visual differentiation.

- Medical devices. Components such as catheter sleeves must be biocompatible and non-irritating.

Conclusion

Silicone color masterbatch is a practical tool for improving product aesthetics and manufacturing consistency. When choosing masterbatch, prioritize compatibility with your silicone system, control the addition rate, and verify color with molded samples. These steps keep your products looking consistent while protecting silicone performance. If you need, we can advise on masterbatch selection for your specific silicone type, curing system, and product design.