“Silicone melting temperature” is one of those search terms we see all the time — especially from buyers comparing silicone to plastics or elastomers like TPE or TPU.

The short answer is simple.

The real answer needs a bit of correction.

Silicone Does Not Have a True Melting Point

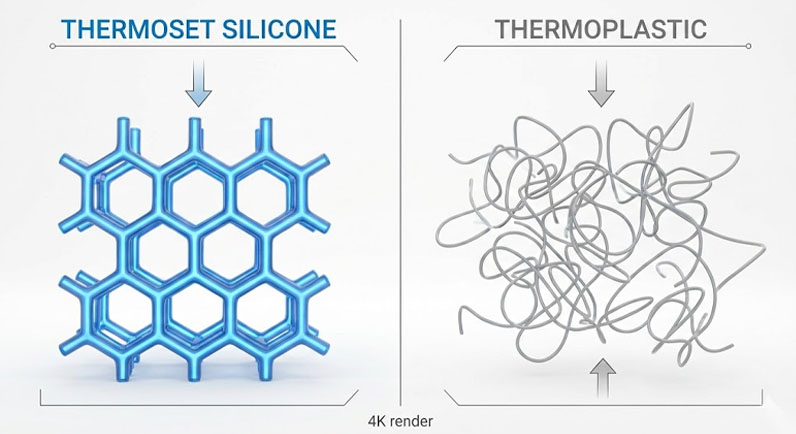

Solid silicone rubber does not melt the way thermoplastics do.

Silicone rubber is a thermoset elastomer. Once it’s cured, its polymer network is locked. Heat does not turn it into a liquid. Instead, at high enough temperatures, silicone will degrade, char, or lose mechanical properties — but it does not flow.

This is the first misunderstanding that causes spec mistakes.

When people ask for “silicone melting temperature,” they are usually trying to understand one of three things:

- Maximum service temperature

- Processing / curing temperature

- Failure temperature under heat exposure

Those are different numbers. Treating them as one is where confusion starts.

Typical Temperature Ranges for Silicone Rubber

Here’s how we frame it internally when answering customers.

Continuous Service Temperature

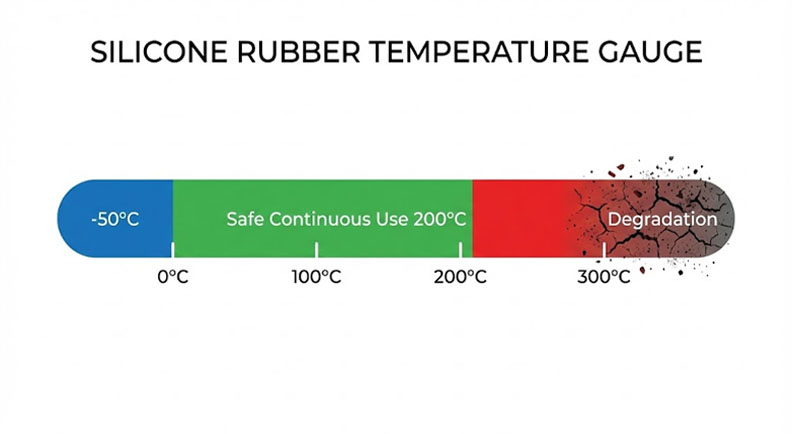

Most industrial-grade silicone rubber can operate continuously around:

- –50°C to +200°C (–58°F to +392°F)

Higher-performance formulations can reach:

- 230–250°C continuous

- Short-term exposure up to 300°C

At these temperatures, silicone remains elastic. No melting occurs.

Degradation Range (Not Melting)

Above roughly 300–350°C, silicone rubber begins to:

- Lose tensile strength

- Harden or embrittle

- Form surface ash or silica residue

This is thermal breakdown, not melting. The material does not drip or flow.

Why Liquid Silicone Rubber (LSR) Confuses the Question

Liquid Silicone Rubber is often misunderstood as “low melting” because it starts as a liquid.

In reality:

- LSR is liquid before curing

- It solidifies via heat-triggered crosslinking

- Typical molding temperatures: 160–200°C

After curing, LSR behaves like any other silicone rubber — no melting point.

So when datasheets list “processing temperature,” that number has nothing to do with melting behavior in use.

Silicone vs Thermoplastics: Why the Comparison Fails

Buyers often compare silicone to materials like PVC, TPU, or TPE and expect a melting point number like:

- PVC: ~160–210°C

- TPU: ~170–200°C

This is the wrong framework.

Thermoplastics:

- Soften

- Melt

- Re-solidify

Silicone rubber:

- Cures

- Stays solid

- Eventually degrades

That difference matters in applications involving ovens, autoclaves, hot-fill, or engine compartments.

What to Ask Instead of “Melting Temperature”

If you’re sourcing silicone parts, the useful questions are:

- What is the maximum continuous operating temperature?

- How long is the thermal exposure (minutes vs years)?

- Is mechanical retention required at high temperature?

- Will the part experience compression set under heat?

Those answers determine material selection — not a melting point value that doesn’t exist.

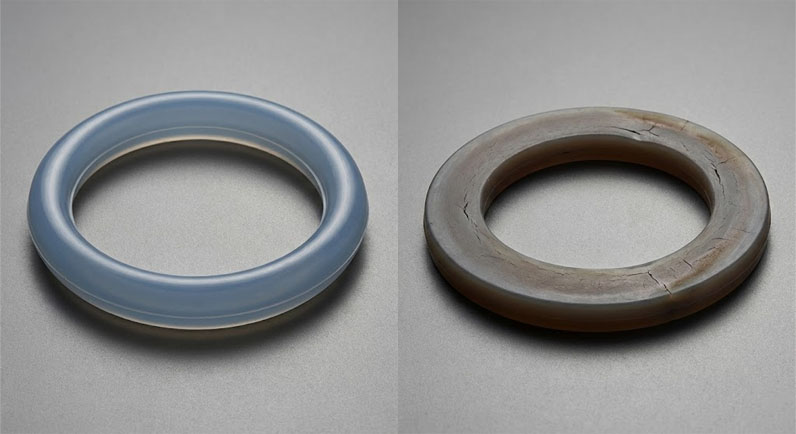

The Boundary Most Specs Miss

Silicone’s strength under heat is time-dependent, not binary.

At 200°C:

- A gasket may last years

At 230°C:

- It may pass short-term testing

- But compression set will creep faster over time

This is why datasheet numbers look generous, but real applications quietly fail earlier than expected.

Not because silicone “melted” — but because it aged.