The industrial sector struggles with finding durable materials that can withstand extreme conditions. Many traditional options fail under pressure, leading to costly replacements and production delays.

Industrial silicone sheets come in various types including solid silicone sheets, foam silicone sheets, reinforced silicone sheets, and specialized formulations. Each type offers unique properties suited for specific applications, with variations in temperature resistance, durability, and chemical compatibility.

I’ve been in the silicone manufacturing business for over a decade now, and one question I hear constantly from clients is about the differences between silicone sheet types. Let’s explore the main varieties and help you determine which might be best for your specific industrial application.

What Makes Solid Silicone Sheets So Versatile in Industrial Applications?

Manufacturing facilities face constant challenges with materials that can’t handle heat, chemicals, and continuous operation. Many traditional rubber products deteriorate quickly, causing unexpected downtime.

Solid silicone sheets are homogeneous, non-porous sheets with consistent density throughout. They typically offer temperature resistance from -60°C to 230°C, excellent electrical insulation properties, and maintain flexibility even after prolonged exposure to extreme environments.

The Fundamental Industrial Workhorse

Solid silicone sheets represent the most common and versatile option in industrial settings. I remember visiting a client’s automotive manufacturing plant where they had been struggling with gasket failures in their high-temperature assembly processes. After switching to our solid silicone sheets, their maintenance calls dropped by nearly 70%.

These sheets are manufactured through compression molding or calendering processes, resulting in a uniform material with consistent properties throughout. The density typically ranges from 1.1 to 1.6 g/cm³, depending on the formulation and fillers used.

Key Properties of Solid Silicone Sheets:

| Property | Range | Benefits |

|---|---|---|

| Temperature Resistance | -60°C to 230°C | Suitable for extreme environments |

| Hardness | 30-80 Shore A | Adaptable to various compression needs |

| Tensile Strength | 4-12 MPa | Reliable under mechanical stress |

| Elongation | 200-800% | Excellent recovery properties |

| Color Options | Transparent, Red, Black, Custom | Visual identification and branding |

Solid silicone sheets excel in applications requiring reliable sealing against liquids and gases. They’re commonly used for gaskets, diaphragms, and electrical insulation. Their non-reactive nature makes them ideal for food processing equipment, medical devices, and pharmaceutical manufacturing.

One important consideration when selecting solid silicone sheets is the hardness rating. Softer sheets (30-40 Shore A) provide better conformability and sealing on irregular surfaces, while harder sheets (60-80 Shore A) offer improved wear resistance and stability under compression.

How Do Foam Silicone Sheets Enhance Cushioning and Insulation?

Traditional insulation materials often fail to provide both thermal protection and compression recovery. This creates inefficiencies in systems that need reliable cushioning alongside temperature resistance.

Foam silicone sheets contain numerous closed or open cells distributed throughout the material, creating a lightweight structure that offers excellent thermal insulation, shock absorption, and compression recovery while maintaining silicone’s inherent temperature and chemical resistance.

The Lightweight Insulation Solution

Foam silicone sheets have transformed how we approach thermal and acoustic insulation challenges in industrial settings. Last year, I worked with a client in the aerospace industry who needed a material that could provide both thermal insulation and vibration dampening in their satellite components. Foam silicone sheets were the perfect solution.

These sheets are produced through a chemical foaming process that creates gas bubbles within the silicone matrix. Depending on the manufacturing technique, we can create either open-cell foams (interconnected cells) or closed-cell foams (isolated cells), each with distinct advantages.

Foam Silicone Sheet Characteristics:

| Characteristic | Open-Cell | Closed-Cell |

|---|---|---|

| Density | 0.2-0.5 g/cm³ | 0.3-0.8 g/cm³ |

| Water Absorption | Higher | Lower |

| Compression Set | Excellent recovery | Good recovery |

| Thermal Insulation | Good | Excellent |

| Sound Dampening | Excellent | Good |

| Typical Applications | Acoustic insulation, Cushioning | Thermal insulation, Flotation |

The cellular structure of foam silicone sheets provides significant weight reduction compared to solid sheets while maintaining many of silicone’s beneficial properties. This makes them particularly valuable in applications where weight is a concern, such as aerospace, portable electronics, and transportation.

Beyond their insulation properties, foam silicone sheets offer excellent compression recovery, making them ideal for gaskets in applications with irregular surfaces or where compression forces vary. Their ability to conform to uneven surfaces creates reliable seals even under challenging conditions.

Why Are Reinforced Silicone Sheets Essential for High-Stress Applications?

Engineers often struggle with finding materials that combine flexibility with dimensional stability. Standard elastomers tend to stretch unpredictably under load, causing alignment issues and premature failure.

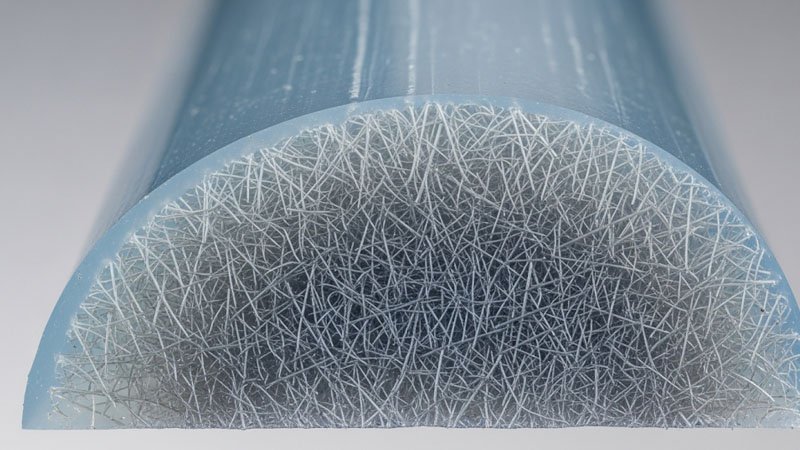

Reinforced silicone sheets incorporate fiberglass, polyester, or metal mesh within the silicone matrix to enhance tensile strength, tear resistance, and dimensional stability while maintaining flexibility. They typically offer 3-5 times the tensile strength of non-reinforced sheets.

Strength Meets Flexibility

Reinforced silicone sheets represent an engineering breakthrough for applications requiring both the elastomeric properties of silicone and enhanced mechanical strength. I recently consulted with a mining equipment manufacturer who was experiencing frequent failures with their conveyor belt skirt seals. By implementing fiberglass-reinforced silicone sheets, they extended their maintenance intervals by over 300%.

The reinforcement process involves embedding a supporting material within the silicone during manufacturing. The most common reinforcement materials include:

- Fiberglass mesh – Provides excellent dimensional stability and heat resistance

- Polyester fabric – Offers good tensile strength with some flexibility

- Metal mesh – Creates maximum tear resistance and stability

- Carbon fiber – Delivers strength with minimal weight addition

Performance Comparison of Reinforcement Types:

| Reinforcement Type | Tensile Strength | Temperature Resistance | Flexibility | Cost Factor |

|---|---|---|---|---|

| Fiberglass | High | Excellent | Moderate | Medium |

| Polyester | Moderate | Good | Good | Low |

| Metal Mesh | Very High | Excellent | Limited | High |

| Carbon Fiber | Very High | Excellent | Moderate | Very High |

The reinforcement typically increases the sheet’s tensile strength by 300-500% compared to non-reinforced silicone, while maintaining much of the material’s flexibility. This combination makes reinforced sheets ideal for applications involving repetitive stress, high pressure, or where dimensional stability is critical.

Common applications include diaphragms for pumps and valves, gaskets for high-pressure systems, conveyor belts for extreme environments, and specialized membranes for filtration systems. The reinforcement also significantly improves tear resistance, making these sheets more durable when fastened with bolts or clamps.

How Do Specialized Silicone Sheet Formulations Address Unique Industrial Challenges?

Standard materials often fall short when facing extreme conditions like high radiation, food processing requirements, or electrical conductivity needs. These limitations force engineers to compromise on performance or durability.

Specialized silicone sheets include FDA-compliant food-grade formulations, electrically conductive variants with carbon additives, high-purity platinum-cured sheets for medical use, and extreme temperature formulations that can withstand up to 315°C or as low as -100°C.

Tailored Solutions for Extreme Requirements

In my years working with industrial clients, I’ve seen the growing demand for silicone sheets that go beyond standard formulations to address specific challenges. One memorable project involved helping a semiconductor manufacturer find a material that could provide both high-temperature resistance and ultra-low particle emission for their clean room equipment.

Specialized silicone formulations represent the cutting edge of industrial elastomer technology. These sheets are engineered with specific additives or processing methods to enhance particular properties while maintaining silicone’s fundamental benefits.

Common Specialized Formulations:

| Type | Key Features | Primary Applications |

|---|---|---|

| Food-Grade (FDA) | Non-toxic, non-marking, compliant with 21 CFR 177.2600 | Food processing, pharmaceutical production |

| Conductive/Anti-Static | Carbon-loaded, electrical resistivity 10³-10⁶ Ω·cm | Electronics manufacturing, explosive environments |

| High-Purity | Platinum-cured, low extractables, minimal outgassing | Semiconductor, medical, aerospace |

| Extreme Temperature | Modified polymers, specialized fillers | Foundries, cryogenic applications |

| Flame-Retardant | Meets UL94 V-0 standards, self-extinguishing | Mass transit, power generation, construction |

The development of these specialized sheets often involves proprietary formulations and manufacturing processes. For example, electrically conductive silicone sheets incorporate precisely distributed carbon particles to achieve consistent conductivity without compromising mechanical properties.

High-purity silicone sheets used in semiconductor manufacturing undergo additional post-curing processes to remove volatile compounds that could contaminate sensitive processes. These sheets typically have extractable content measured in parts per million rather than the parts per thousand found in standard industrial grades.

Flame-retardant formulations represent another critical specialized category, incorporating additives that inhibit combustion without leaching harmful substances. These materials are increasingly important as safety regulations become more stringent across industries.

Conclusion

Industrial silicone sheets come in diverse forms to meet specific challenges across industries. Whether you need solid, foam, reinforced, or specialized formulations, understanding these differences helps you select the right material for your application.