Shore A hardness is usually the most visible number on a silicone datasheet—and one of the most misunderstood.

Many teams treat it as a simple soft-versus-hard decision:

- Lower Shore A = softer feel

- Higher Shore A = better durability

In real applications, that linear logic often leads to sealing failures, user complaints, or parts that age far faster than expected.

Shore A hardness is not a single-performance attribute.

It simultaneously affects feel, sealing behavior, and long-term durability, and those effects frequently pull in different directions.

This guide helps engineers choose the correct silicone Shore A hardness for seals, gaskets, and consumer products.

What Shore A hardness actually measures (and what it doesn’t)

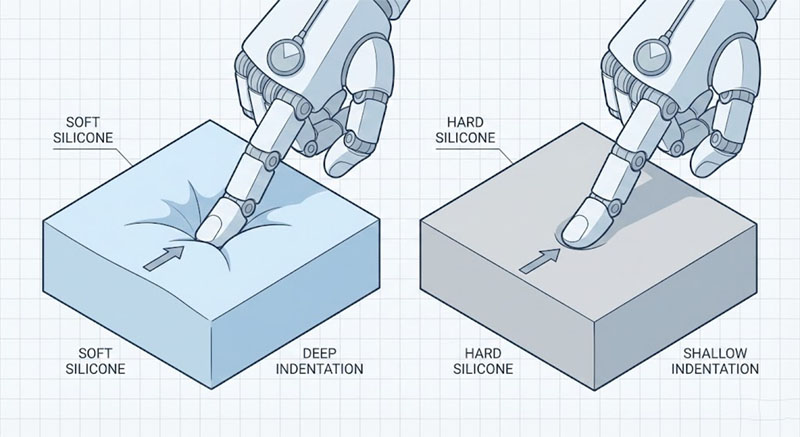

Shore A hardness measures a material’s resistance to short-duration, localized indentation under standardized conditions.

It can tell you:

- How “soft” a material feels at first touch

- Relative resistance to surface penetration

It does not directly tell you:

- Whether a seal will maintain contact over time

- How well the material recovers after long-term compression

- How it behaves after thermal aging or repeated cycling

That’s why two silicone parts with the same Shore A rating can perform very differently in real use.

How Shore A hardness affects feel

Feel is the area where Shore A is most often oversimplified.

The common mistake

“Users say it feels too hard—let’s drop Shore A by 10 points.”

Short-term, this often works.

Long-term, it frequently creates new problems.

What actually happens

- Low Shore A (20–30A)

- Very soft initial feel

- Higher risk of “skin drag” or tacky perception

- Surface chemistry and post-processing have outsized impact

- Mid Shore A (40–50A)

- Most stable perceived feel over time

- Slower user perception drift

- Common sweet spot for consumer-contact products

- High Shore A (60A+)

- Feels firm at first contact

- Can still feel compliant in thin-wall designs

- Relies more on geometry than material softness to tune feel

Key point:

Feel is the result of Shore A × geometry × surface condition, not hardness alone.

How Shore A hardness affects sealing

This is where Shore A selection causes the most expensive surprises.

Intuition vs reality

- Intuition: Softer seals better

- Reality: Too soft often fails sooner

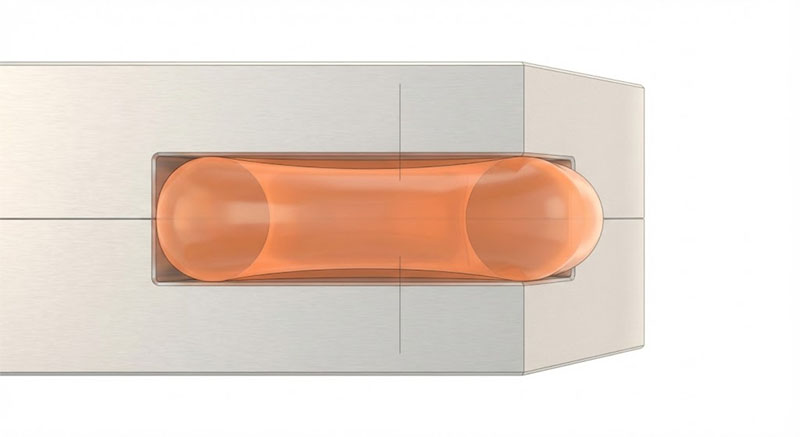

What sealing actually depends on

- Achieved compression

- Elastic recovery over time

- Tolerance to misalignment and variation

Performance by hardness range

- Low Shore A

- Excellent initial sealing

- Higher risk of extrusion, shear, or permanent set

- Seal force drops quickly after heat or aging

- Mid Shore A

- Most consistent long-term sealing

- Wider tolerance window in assembly

- Dominant range for gaskets and O-rings

- High Shore A

- Requires higher assembly force

- Maintains sealing force better over time

- Preferred for dynamic or higher-pressure applications

Rule of thumb:

Most seal failures are not caused by being “too hard,” but by not recovering after compression.

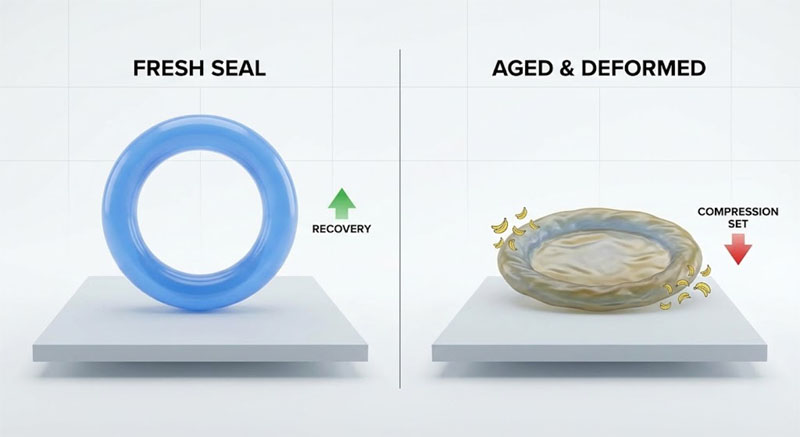

How Shore A hardness affects durability

Durability is where Shore A behavior becomes non-linear.

Two common misconceptions

- Harder always lasts longer

- Softer always wears out faster

Neither is reliably true.

What actually happens

- Low Shore A

- More prone to fatigue cracking

- Greater sensitivity to oils, sweat, and cleaning agents

- Slower shape recovery

- Mid Shore A

- Best balance of fatigue resistance and elasticity

- Aging effects are more predictable

- Widest and most forgiving process window

- High Shore A

- Strong resistance to tearing and extrusion

- More stable under high-frequency cyclic loads

- Can show brittleness sooner in thin-wall designs

Durability isn’t about surviving one cycle—it’s about behaving acceptably after hundreds of thousands or millions of cycles.

Case study 1: 30A Silicone Seal Failure in Wearable Devices

Application: Wearable device sealing ring

Initial choice: 30A (comfort-driven)

Observed issues

- Seal failure after 3–6 weeks

- User complaints of deformation and tackiness

Root cause

- Shore A too low for continuous compression

- Body temperature accelerated permanent deformation

Correction

- Increased hardness to 45A

- Minor cross-section geometry change

Result

- No noticeable loss in perceived comfort

- Service life increased by more than 4×

Case study 2: Harder fixed the seal—not the leak

Application: Reusable food container

Initial choice: 35A

Observed issues

- Leakage after hot-water use

- Loss of shape after repeated cycles

Adjustment

- Increased hardness to 55A

- Added compression preload

Result

- Stable sealing across temperature cycles

- Fewer user complaints due to reduced required closing force

How to select Shore A hardness correctly

Don’t start with hardness.

Start by answering these questions:

- What is the dominant failure mode? Leakage, collapse, fatigue, or feel complaints?

- What is the long-term mechanical state? Continuous compression, cyclic loading, thermal aging?

- Can geometry reduce material stress? Wall thickness, compression ratio, contact area?

Hardness selection should be the last step, not the first.

We prepared a table below summarizes typical Shore A trade-offs in silicone components

Silicone Shore A Hardness – Quick-Reference Selection Table

| Shore A Range | Feel & User Perception | Sealing Behavior | Durability & Aging | Typical Use Cases | Common Failure Risks |

|---|---|---|---|---|---|

| 20–30A | Very soft, compliant, high initial comfort | Excellent initial seal, poor long-term recovery | Fast compression set, fatigue cracking risk | Infant products, soft grips, low-load interfaces | Shape collapse, tackiness, seal loss after aging |

| 30–40A | Soft but more controlled feel | Good initial sealing, moderate stability | Sensitive to heat and continuous compression | Light-duty seals, comfort-driven consumer parts | Gradual sealing force decay, deformation |

| 40–50A | Balanced, stable over time | Most reliable long-term sealing | Best fatigue resistance, predictable aging | Gaskets, O-rings, wearables, consumer seals | Usually geometry-related, not material |

| 50–60A | Firm feel, still compliant in thin sections | Requires higher assembly force, stable seal | High resistance to extrusion and wear | Reusable containers, appliance seals | Assembly force complaints if geometry is wrong |

| 60–70A | Hard, precise tactile response | Strong sealing once compressed | Excellent tear resistance, may embrittle | Dynamic seals, higher pressure systems | Brittleness in thin walls, tolerance sensitivity |

The boundary most teams miss

Shore A hardness is a system variable.

It changes:

- How users perceive quality

- How sealing performance decays over time

- Whether failure is gradual—or sudden

When Shore A is wrong, problems rarely appear immediately.

They show up during validation, aging tests, or customer use—when changing hardness is already expensive.

That’s why Shore A selection is less about softness, and more about how the entire system behaves over time.

Click Silicone Shore A Hardness If you want to learn more basic information.